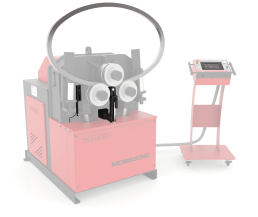

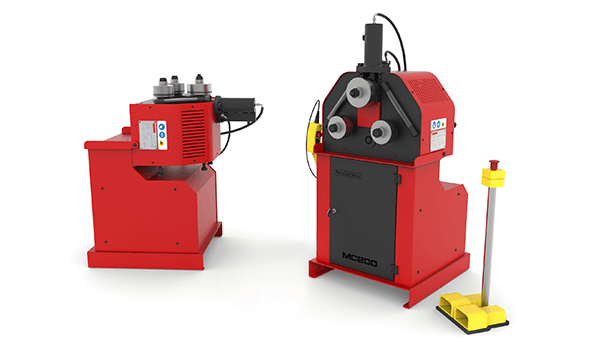

The NEW MC650 Nargesa section and pipe bending machine is specially designed to carry out mass production through the control, which saves the position of the rollers in each curve to repeat the same operations later, without longitudinal positioning control. It is ideal for manufacturing flanges, greenhouses, railings, large structures for construction... Maximum capacity for bending round pipe: 4” inches or 101,6 mm.

The MC650 NARGESA section and pipe bending machine is made of welded and machined sheet steel, making it very tough and stable. It is ideal for manufacturing flanges, greenhouses, railings, large structures for buildings such as circular beams for roofs, domes, bridge abutments, metal pergolas, curved marquees, structures for tunnels... Urban furniture such as street lamps, protections for roundabouts, bicycle parking stands, tree protectors, railings, public transport marquees, bollards or moveable bollards, children's play parks and all sorts of circular figures in different large and small sections and tubes. Its capacity, versatility, control panel and 4.0 technology make the MC650 bender an ideal machine for bending not only for your company, but for other clients as well.

All Nargesa products are according to the CE standards on manufacturing industrial machinery.

Our customers say

Technical features

Its robustness, axis diameter, reduction capacity, Control Panel and 4.0 Technology make out of it one of the best bending machines on the market in the three-driven roller category, an essential condition for working tubes and large profiles with a perfect finish.

4.0 Technology: The advantages of having this technology in a machine are endless, so we’re only going to mention the most relevant. Whenever a customer agrees, the manufacturer may remotely connect to their machine to do any software updates completely free of cost and detect any anomalies in the machine without needing to travel to the machine site. Customers are notified when preventive maintenance must be done on the machine along with many other advantageous features.

All-new EcoMode: We are well aware of the importance of saving energy nowadays. This is why our new machinery features an EcoMode which automatically disconnects the electric parts consuming the most energy if it detects any period of inactivity. Just press the movement button to restart production. We believe this feature is of vital importance to our customers for their savings as well as for the sustainability of the planet. After all, we’re a company that’s highly committed to the environment.

Robustness: The weight of the machine in comparison to other brands provides an idea of how it’s built. Some models can double the others in weight. These are not DIY machines; they’re pipe benders that can work 24 hours a day. Made of steel sheet, which is tempered in areas subject to wear, and activated with a pinion planetary gear system. We do not use chains or other weak devices that could affect how the machine operates in the future.

Vertical and horizontal position: It is important to note that when purchasing a bending machine, you need to be able to position it horizontally as well as vertically. If the piece to be manufactured has diameters less than 1500 mm, working in a vertical position is recommended. On the contrary, when the bend diameters are increased above this level, work should be done in a horizontal position. Due to the proper support, this prevents the weight of the piece from affecting the end results. Bending is also done in a horizontal position to overcome clearance issues at the customer’s facilities. The MC650 bending machine can be operated in both positions (vertical and horizontal) which proves its great versatility.

An electronically-controlled asymmetric roller position: Asymmetric bending machines offer certain advantages over pyramidal bending machines. The lower axles rise and drop in a kidney-shaped movement. This means the distances between centers are variable which saves materials and, as a result, provides for optimal use of the profile or pipe which can be bent almost to the end. Another advantage is that bends can be made with much smaller radiuses than with pyramidal bending machines as the rollers can be practically moved together.

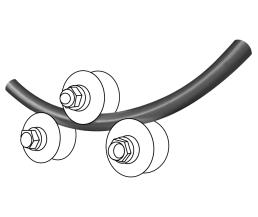

3 power rollers: The 3-roller drag system makes the work easier, mainly when bending round or square pipes. This prevents possible marks on the material which is a significant improvement over 2-power axle bending machines which feature lower layer-cut rollers for good traction. All bending work is done faster with a 3-power axle bender.

Side hardeners: The side hardeners on the MC650 model can correct profile bends in up to 6 different planes: forward, backward, upward, downward, in a left rotation and in a right rotation over the same axis. Likewise, the hardeners can be adjusted to force the profile to create a spiral. It also features a rotary device that’s essential to being able to bend the angle or establish the radius resulting from the mechanically-formed piece.

Rotation speed and programmable axle adjustment: In most cases, the production speed can be increased when the profile to be bent is small and the machine is programmed to do so. When the profile used is larger, you can also reduce the operating speed to adjust it appropriately for a proper bend. Likewise, the bend adjustment speed can be programmed on the first piece or only piece, facilitating and streamlining the most complex bending work. Unlike other brands, the Nargesa MC650 comes standard with this speed variator for roller rotation and position adjustment.

Possibility of incorporating the NEW CNC Bending Kit: This kit can be installed on the MC550 Bender at any time, even after the machine has been purchased. Its main advantages are: Predictive intelligent system for achieving the desired radius on the first attempt. Speed control and axis interpolation for perfect results and smooth transitions between segments. High-resolution encoder with 4096 pulses and a quadrature decoder (see optional accessories at the bottom of the page).

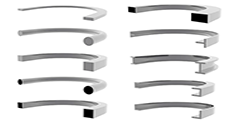

- It's equipped with 9 standard rollers by means of which you can make all kinds of profiles. Square pipe, rectangular, solid square bar, round and rectangular, U profile, T profile, angle, flat bar, edge flat bar... Optional rollers can be supplied for round pipe or tube (See optional accessories at the bottom of the page).

- It is specially designed to carry out mass production through the control, which saves the position of the rollers in each curve to repeat the same operations later. Without longitudinal positioning control.

- Max. bending capacity in round pipes: 4" inches or 101,6 mm.

- Three traction rollers, ideal and essential to bend round pipe, with smooth surface not to get the pipe or profile damaged.

- Safe transmission between tempered planetary pinions by induction.

- Tempered and rectified F-154 steel axles.

- Electrohydraulic drive system.

- Diameter of the lower axles: 65 mm.

- Diameter of the upper axle: 80 mm.

- Net length of the axles: 130 mm.

- Outer roller diameter: 202 mm.

- Bend regulation independent of the lower rollers which allows much smaller bends in diameter and takes better advantage of the material than pyramidal bending machines.

- Electronically-controlled asymmetric roller position.

- ESA S625 panel comes with the machine.

- Main motor: 3 KW/4 CV.

- Hydraulic motor unit: 0.75 KW/1 CV.

- 3-phase voltage: 230/400 V.

- Adjustable roller speed: from 3 to 8 RPM.

- Palletized lower table so it can be easily moved to the working site or storage.

- Wooden pallet and 3-layered cardboard box suitable for sea freight.

- Optional: wooden packaging NIMF15.

All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard from the best European leading trademarks, with technical suppeort all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato...

Nargesa section bending machines capacity

In the PDF file you will see and download the bending capacity for Profile Formers. This are guidance sizes, it always depends a lot on the material hardness and quality of the pipe of profile.

Download (170.72 KB)

Optional accesories for MC650 section and pipe bending machine

CNC Bending Kit · MC650

The ALL-NEW CNC bending kit is the ideal accessory designed and manufactured to get the most out of Nargesa MC650 pipe and profile benders. This kit can be installed whenever the customer wants; in other words, some time after having purchased the bending machine.

Its incredible smart predictive system, which is being offered for the first time ever in the world’s tube and profile bending industry, guarantees any desired radius right away. Unbeatable ease of programming for operators, speed and reliability for unique pieces and large series. The CNC bending kit minimizes material waste, increases productivity and speeds up the creation of complex pieces. It offers exceptional repetitiveness, a simple, intuitive and powerful interface with CNC ESA S625 control, absolute connectivity for industry 4.0, safety, durability and maximum efficiency.

The interpolated axle control and independent speed management guarantee excellent results and soft transitions, which leads to greater and better productivity with perfect mass-produced pieces and exceptional repetitiveness.

Packaging

Dimensions: 920 x 620 x 340 mm

Weight: 37 Kg.

Download (226.86 KB)

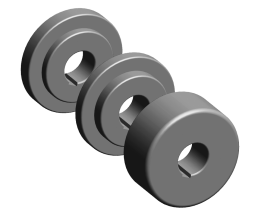

Treated steel rollers MC650

Rollers made of Steel F155 and treated to 62 Rc. Suitable for bending all kind of round steel or stainless steel pipes.

Always clean up the rollers well before using stainless steel not to get the pipe contaminated.

Download (460.21 KB)

Sustarin rollers MC650

Rollers made of Sustarin to bend round stainless steel pipes, aluminium and delicate materials with thickness not bigger than 2.5mm.

Sustarin rollers do not danage nor get the pipe contaminated.

Download (680.01 KB)

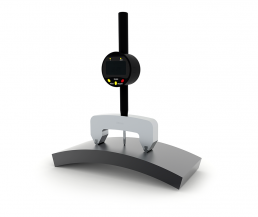

High precision digital radius gauge

Especially designed for measuring radii on profiles.

REF: 140-MED08-00001

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

The High precision digital radius gauge measures radii in spherical objects such as tubes, profiles and pipes in a quick and accurate way.

It is really fast and easy to use! It indicates the inner or outer radius of the part we are bending without removing it from the machine and without needing to previously draw and cut a guide template.

- Includes 3V CR2032 lithium battery

- Includes 3 measurement arcs (100, 200 and 300 mm).

- Supplied with a shock-resistant stainless Steel briefcase.

Included accesories for MC650 section and pipe bending machine

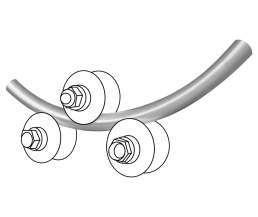

Standard rollers MC650

It's equipped with 9 standard pieces, by means of which the user can work all kinds of profiles. Square, rectangular pipe, solid round and square bars, U Profile, T profile, angle, flat bar, edged flat bar...

Adjustable rollers, by washers with the size of profile or pipe which allows us to make bending to different pipe or profile sizes.

Steel rollers F155 treated and rectified.

Download (1.46 MB)

+ Info for MC650 section and pipe bending machine

ESA S625 CONTROL CHARACTERISTICS

Nargesa MC650 pipe benders are controlled with a very intuitive and easy-to-use 7” color touchscreen with the latest 4.0 technology. You only need to do the first piece and save each step so that the control will repeat the same operations on the other pieces in the same series automatically, without longitudinal positioning control.

You can add the type and dimensions of the pipe or profile, the material and position of the rollers to the program so all of this is saved for the following series.

These are some of the most relevant features of this control system.

- Stores up to 10,000 programs.

- An endless number of different bends on the same piece can be programmed.

- Dimensions may be programmed in inches or

- millimeters.

- A library of available rollers with the possibility of programming new ones.

- A library with different profiles, pipes and materials.

- Can be programmed in more than 20 different languages.

- Automatic or manual rotation speed adjustment from 3 to 7 rpm.

- Manual or automatic operation.

- 4.0 Technology

- Joystick to activate the rotation and positioning movements.

- On-screen alarm diagnostics.

- Preventive maintenance warning.

- Can be remotely connected by the manufacturer without having to travel to the machine site.

- 7” color touchscreen with 800 x 480 resolution.

- 128 MB silicon disk.

- 2 analog inputs, 12 bit resolution.

- 16 digital inputs (24 Vdc).

- 16 digital outputs (24 Vcc, 0.7 A max.) Protected against overloads and short circuits.

- 1 RS232 serial port.

- 1 CAN port with 9 D-Sub F connector contacts.

- 24 Vdc power source

- 1 USB port.

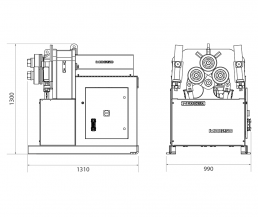

Dimensions of the machine MC650 section and pipe bending machine

Characteristics of the packaging MC650 section and pipe bending machine

Nº Pallets: 1.

Width: 1380 mm 54,3

Length: 1070 mm 42,1"

Height: 2090 mm 82,3"

Volume: 3,08 m3

Nett weight: 1290 Kg 2844lb

Gross weight: 1321 Kg 2912.3lb

Tariff Item Code: 84622900

Other Features:

- Palletized bench to transport the machine easily to the working place or storage.

- The machine is sent completely mounted.

- Packaging with wooden pallet and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

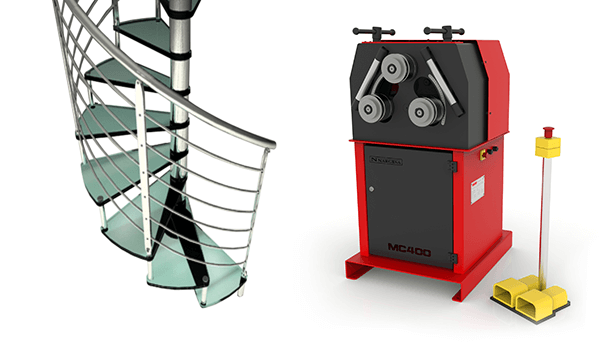

Uses of the machine MC650 section and pipe bending machine

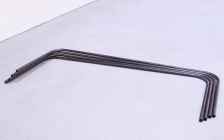

The MC650 NARGESA high capacity section and pipe bending machine can bend all types of sections: Round, square and rectangular tube, UPN channels, IPN beams, T section, angle, flat plate, edge bending... Ideal to make and curve flanges, greenhouses, railings, tables, chairs, doors, windows, street lamps, urban furniture... Especially designed to manufacture large structures for construction, such as circular beams for roofs, domes, bridge abutments, metal pergolas and curved marquees. Urban furniture such as street lamps, protection for roundabouts, bicycle parking stands, tree protectors, railings, public transport marquees, bollards or moveable bollards, children's play parks and all sorts of circular figures in different large and small sections and tubes. Manufacturing of heat exchangers in copper, aluminum, brass, bronze, iron, steel... especially ideal for bending coil heat exchangers. The MC650 bending machine can also carry out work on small sections, tubes and pipes. The design of the rollers allows them to be adjusted to very small and large diameters alike without the need for additional rollers. Supplied with 9 rollers to bent all the sections and tubes most commonly used in the market in any part of the world. Can bend tubes in millimetres as well as inches. Ideal for manufacturing of heat exchangers in copper, aluminum, brass, bronze, iron, steel... especially for bending coil heat exchangers. The MC650 bending machine has sufficient capacity to enable you to offer bending services to other companies.

A great business opportunity!