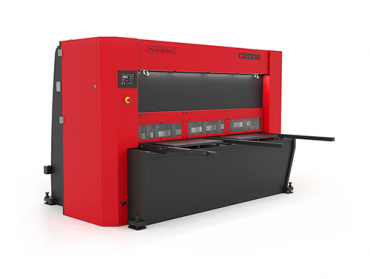

The latest generation CNC vertical cutting shears NARGESA, models C2006 and C3006, are made from welded and stabilized steel that allows them to withstand great stresses without any deformation.

Frequently Asked Questions about NARGESA Hydraulic Shears

What cutting capacity do these shears have in terms of material thickness?

Hydraulic shears can cut large thicknesses such as 20 or 25 mm. However, times change and it is most common to use shears for thicknesses up to 6 or 8 mm, like the Nargesa C2006 model with a cutting length of 2 meters and the C3006 with a total length of 3 meters.

For thicker materials, handling becomes complex and dangerous, and companies choose to buy laser cutting equipment for much thicker materials, avoiding many problems and significantly improving quality and comfort.

Can the cutting angle be adjusted?

Yes, it is possible to adjust the cutting angle in most shear models on the market.

In pendular (swing) cutting shears, adjusting the cutting angle and the clearance between the blades is mandatory; these typically only have two cutting edges. On the other hand, vertical cutting shears up to 6 mm, such as the Nargesa C3006 and C2006 models, do not require adjustment of either blade clearance or cutting angle. The cut is more like scissors and much cleaner.

The blades of vertical cutting shears last much longer, not only because they have twice as many cutting edges but also because of the blade lowering system.

What types of materials can be cut with these shears?

There are many materials that can be cut with a shear, including paper, cardboard, plastics, iron, aluminum, brass, copper, stainless steel, and many others.

Do you offer maintenance services and spare parts for the shears?

Yes, we offer maintenance services and spare parts for all Nargesa guillotines.

The shear is usually a machine that requires minimal maintenance, both mechanical and hydraulic types. Greasing the moving parts indicated by the manufacturer along with lubricating the stop screws are basically the only tasks needed to keep a shear in good condition.

Regarding spare parts, pendular shears experience more blade wear, while vertical cutting shears such as models C2006 and C3006 have much lower blade wear, with 4 cutting edges compared to the 2 of pendular types. We should also highlight that vertical cutting blades can be easily sharpened, avoiding the need for replacement.

Many of our customers have blades that are 20 to 30 years old and still working.