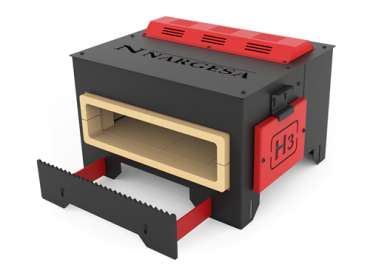

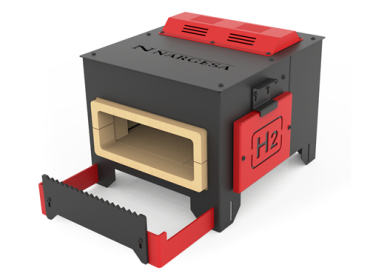

The NEW Nargesa H1, H2, and H3 Forging Furnaces have been designed for heating iron. SAFER, MORE EFFICIENT, and 100% ENVIRONMENTALLY FRIENDLY.

Nargesa propane forges are used in ornamental blacksmithing to heat iron until it becomes malleable and can be shaped into the desired forms—working the ends of rods, making horseshoes, knives, swords, axes, all kinds of artistic forged pieces, iron sculptures and decorative elements, garden iron furniture, wrought iron chairs, wrought iron tables, etc. They are a great substitute for the traditional forge—much cleaner, faster, and more effective.

Frequently Asked Questions About NARGESA Forging Furnaces

Can forging furnaces be used for welding?

Forge welding has been used since ancient times, even in the Middle Ages or earlier. It consists of heating the material to a specific temperature depending on what is being welded. Both pieces are heated and then hammered together until they fuse. This method is often stronger than filler welding. It's important to ensure the surfaces are clean and that the furnace or forge temperature does not exceed 1300°C, as the iron could start to spark and melt.

With the Nargesa H1, H2, and H3 forging furnaces, we achieve the ideal temperature for forge welding.

Which furnace is best for forging knives?

All Nargesa furnaces (H1, H2, and H3) are ideal for the knife-making industry, as they feature side openings that allow for heating longer-than-usual materials, achieving even heating of knives or swords. Another advantage of our furnaces is that, if you need to heat smaller materials, you can close the side openings to retain heat within the furnace chamber and save gas. Depending on the size of the pieces to be made, we would choose one model or another.

What is the maximum temperature they can reach?

Nargesa furnaces reach a maximum temperature of 1300°C, which is sufficient to cover virtually all the needs of a blacksmith. At temperatures above 1300°C, iron begins to spark, and there is a risk of losing the piece as some parts may begin to melt. The vermiculite lining—a 100% natural material with very low thermal conductivity—allows us to reach high temperatures without using too much gas and without damaging the exterior of the furnace, as it doesn’t let heat escape like other materials. And very importantly: it is non-toxic, unlike ceramic fiber.

What type of gas is used?

We currently recommend using propane gas, as it offers multiple advantages over other gases such as natural gas or butane. Its main benefits include:

- Higher calorific value, greater than butane.

- Higher temperatures, ideal for forging processes.

- Easier transport, as it doesn’t require a fixed connection like natural gas.

- Easier ignition and a more stable and even flame.

- Cleaner combustion, with less soot and residue that could contaminate the work, compared to coal or kerosene.

Unfortunately, it is becoming increasingly difficult to find high-quality coal for forging. If our location is in a central area, coal particles from the chimney may cause issues. Furnaces are much faster than traditional forges—imagine you only need to heat a few pieces; once everything is ready, with the furnace, they would already be hot. Another advantage of the furnace is that you don’t have to worry about overheating and damaging the pieces. There are many advantages of the furnace over the forge.