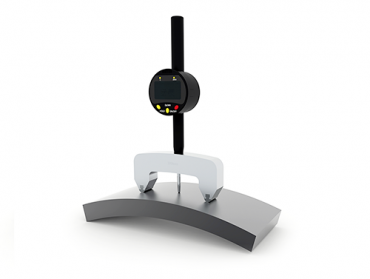

High precision digital radius gauge

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

View productThe Nargesa High-Precision Radius Gauge is specifically designed to measure radii on curved parts, both internal and external, as long as the surfaces where the gauge rests are smooth and regular.

This equipment allows for highly accurate verification of the radius of curvature of a wide variety of metal profiles, such as:

Optimal usage conditions:

The Nargesa High-Precision Digital Radius Gauge offers extremely high accuracy, designed to meet dimensional control requirements in demanding industrial applications.

Technical accuracy of the equipment:

This allows for reliable and repeatable results, even on large radii up to 11,250 mm (443 inches) with the standard equipment, or up to 20,000 mm with an optional arc, as well as on small radii, thanks to the length and design of the probe.

Factors influencing accuracy:

Thanks to this precision, the Nargesa digital gauge is ideal for quick verifications during the bending process, without needing to disassemble the part or use manual templates.

Yes, the Nargesa High-Precision Digital Radius Gauge is fully suitable for measuring radii on tubes, angles, curved profiles, and other elements with circular or curved geometry.

It is also suitable for:

Usage conditions:

The only essential requirement is that the part’s surface must be sufficiently smooth and uniform, which ensures proper contact with the gauge and accurate readings. The material does not matter: as long as the surface is curved, clean, and free of irregularities, the equipment can be used reliably.

This makes it ideal for applications in:

The Nargesa High-Precision Digital Radius Gauge can analyze a very wide range of radii, from very small radii to large-scale curves. It is capable of measuring:

The equipment comes with three interchangeable standard arcs, plus an optional arc for extremely large radii. The capacity of each arc is detailed below:

Measuring arcs and compatible ranges:

This additional 400 mm arc, available as an optional accessory, significantly expands the equipment’s capacity, allowing for measurement of radii in large-scale metal structures, industrial bends, metal roofing, architectural arches, etc.

Thanks to this range of arcs, the equipment can be used for radius measurements in a vast variety of parts, from small components to large-scale structures, all with up to 0.01 mm precision and without needing to disassemble the part or create templates.

No, the Nargesa High-Precision Digital Radius Gauge does not require frequent calibration. Its robust and precise design maintains calibration even after intensive use. However, it is recommended to verify or calibrate the equipment in certain situations, such as:

Calibration process:

This easy calibration process allows the user to verify precision at any time, always ensuring reliable results without interrupting the workflow.

Yes, the Nargesa High-Precision Digital Radius Gauge has been specifically designed for use in industrial environments where robustness, precision, and ease of use are required.

It is prepared to work in manufacturing workshops, bending plants, production lines, or assembly areas, withstanding typical industrial conditions such as:

It can also be used outdoors, as long as the following are avoided:

Although it is a durable and resistant piece of equipment, as a digital precision instrument, it is recommended to protect it from moisture to avoid potential electronic failures or data reading errors.

In short, it is an ideal tool to facilitate bending and forming work on-site, both indoors and outdoors, as long as basic protective precautions are taken.

The Nargesa High-Precision Digital Radius Gauge operates with a 3V CR2032 lithium battery, included with the equipment. This is the same type of battery used in electronic measuring devices such as digital calipers or digital micrometers.

Battery life depends on usage, but under normal conditions it provides several months of autonomy, even in industrial environments.

Its power consumption is very low, thanks to its efficient LCD screen and auto shut-off system after a period of inactivity.

Advantages:

In summary, the equipment offers long-lasting and hassle-free battery life, ideal for daily use in professional settings.

Yes, the Nargesa High-Precision Digital Radius Gauge is fully compatible with industrial metrology standards, both in terms of accuracy, repeatability, and clarity of result readings.

Features that make it suitable for metrological use:

Application in industrial environments:

Its precision makes it compatible with control procedures under ISO 9001, ISO 2768, and other industrial quality systems, especially in bending, metal forming, and structural fabrication processes.

There are more affordable radius gauge sets on the market, generally equipped with small arcs (25 to 100 mm) and intended for very small radii. However, these models have significant technical limitations that directly affect precision, versatility, and productivity.

In summary, while more affordable alternatives exist, the Nargesa Digital Radius Gauge offers a professional and precise solution that prevents costly errors and adapts to a wide variety of industrial applications, resulting in real savings in the medium and long term.

Be part of our Nargesa Community and get all information of the branch, demo clips, campaigns in Machinery…