Ring roller bender section machine MC150B

The pipes and profiles pyramidal bending machine Nargesa MC150B is made of machined steel, with two traction rollers, hardened gear transmission. Maximum capacity for bending round pipe: 2" inches or 50 mm.

View product

Ring roller bender section machine MC200

Ring roller bender and section bending machine MC200 NARGESA fabricated in steel, two traction rollers, pinion transmissions, treated and rectified. Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

View product

Profile bending machines MC400

Bending machine MC400 NARGESA is made of steel, it has got three traction rollers, pinion transmissions, treated and rectified axis. Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

View product

Hydraulic section bending machine MC200H

Hydraulic section bending machine MC200H NARGESA fabricated in steel, two traction rollers, pinion transmissions, treated and rectified axis. Maximum capacity for bending round pipe: 2" 1/2 inches or 70 mm.

View product

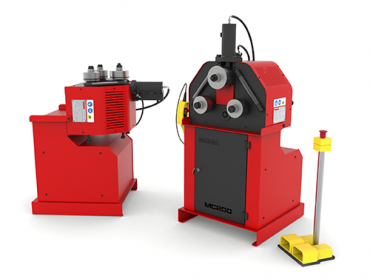

MC550 section and tube bending machine

The BRAND NEW Nargesa MC550 section and tube bending machine has been fully designed and manufactured in our facilities. It has been conceived to make large production of parts through its Control Panel, which registers the position of the rollers in each curve and repeats the same operations whenever required. Without longitudinal positioning control. Maximum capacity for bending round pipe: 3” inches (76,2 mm) or 80 mm.

View product

MC650 section and pipe bending machine

The NEW MC650 Nargesa section and pipe bending machine is specially designed to carry out mass production through the control, which saves the position of the rollers in each curve to repeat the same operations later, without longitudinal positioning control. It is ideal for manufacturing flanges, greenhouses, railings, large structures for construction... Maximum capacity for bending round pipe: 4” inches or 101,6 mm.

View product

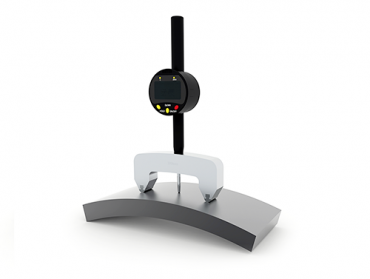

High precision digital radius gauge

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

View product