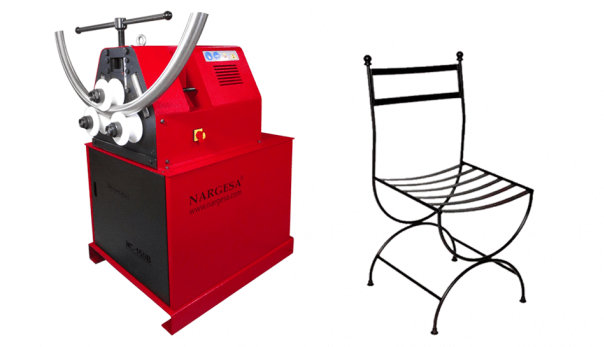

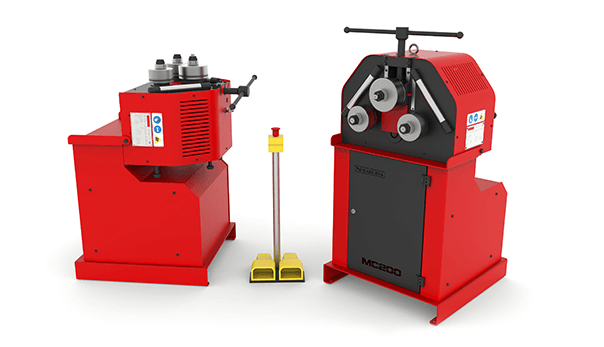

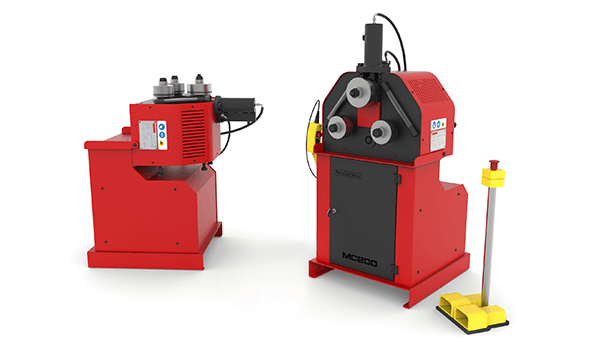

The pipes and profiles pyramidal bending machine Nargesa MC150B is made of machined steel, with two traction rollers, hardened gear transmission. Maximum capacity for bending round pipe: 2" inches or 50 mm.

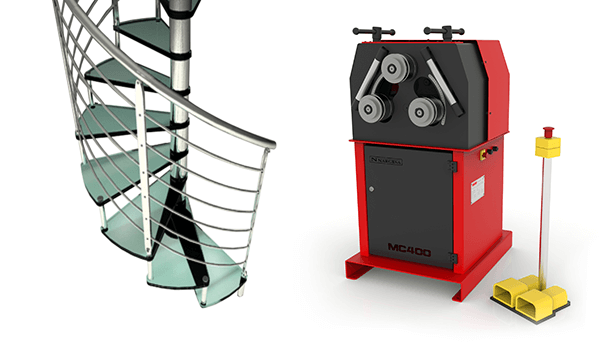

Section and pipe bending machine MC150B NARGESA. Our pipe bender MC150B is designed to minimize the manufacturing cost and provide maximum performance when bending pipes and profiles. It has been manufactured for different profiles such as flat bar or bar section, T-profile, rolling U-profile, bending angle, bending solid rod, both square and round types, spiral tube or even to perform square, rectangular or round pipe in different materials: iron, carbon steel, stainless steel, brass, copper, aluminum. The purpose of these bending operations varies from making greenhouses, tables, chairs, car guards, doors, windows, railings, fences up to countless metal products.

All Nargesa products are according to the CE standards on manufacturing industrial machinery.

Our customers say

Technical features

The pyramidal section bending machine MC150B has been designed by our team of engineers in Nargesa for making bending works in different shapes and materials at a very low cost for the customer. The secret is the mass production of it. Many of our customers were asking us to make a bending machine at an affordable price, easy to use and strong as all Nargesa’s products. One of the main reasons for purchasing this one is not to rely on third parties to perform the bending jobs. Repeated delays caused by not depending on our own is always more expensive than an investment on our MC150B bender.

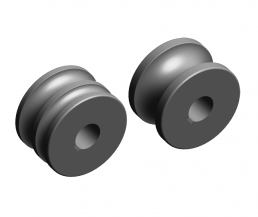

- Two drive rollers. The two lower rollers are motorized and knurled for better grip.

- Secure transmission by using flat hardened pinions.

- Diameter of axes: 40 mm.

- Useful axes length: 74 mm.

- Center distance between lower axes: 230 mm

- Maximum capacity for bending round pipe: 2" inches or 50 mm.

- Bending regulation by the upper shaft, which allows to curve tube and profile dimensions and profiles of large diameter without deformation.

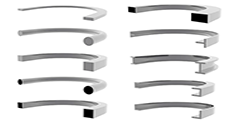

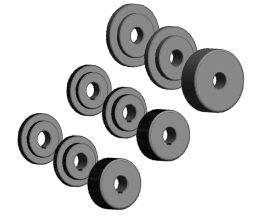

- We supply the section bending machine MC150B with 9 rollers and standard washers, that can be combined and make all kinds of profiles. (Square pipe, rectangular, square bar, round and rectangular bars, U profile, T profile, angle, flat bar, edged bar ...) It is only for special round pipes when we need special rollers.

- Millimeter scale for bending in the upper shaft.

- Two working positions, horizontal and vertical in the same workbench.

- Correction rollers on the sides to control the bending deformation when making spirals and spiral staircases.

- Base cupboard for rollers and accessories.

- Motor Power: 0.75 KW / 1 HP

- Voltage supply: Single phase 230 V (For other voltages, contact the manufacturer)

- Rollers speed: 6 RPM

- Lower bench palletized to easily transport the machine to the workplace or store it in case of lacking space.

- The machine is shipped fully assembled, you only need to connect it to the power supply.

- Palet made of steel and 3 layer cardboard box suitable for seafreight.

- Optional: Fumigated wooden box NIMF15.

All our products are manufactured in our facilities in Spain. The hydraulic and electronic components are completely standard and from leading European brands, with service worldwide: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Nargesa section bending machines capacity

In the PDF file you will see and download the bending capacity for Profile Formers. This are guidance sizes, it always depends a lot on the material hardness and quality of the pipe of profile.

Download (170.72 KB)

Optional accesories for Ring roller bender section machine MC150B

Treated steel rollers

Rollers made of Steel F155 and treated to 62 Rc. Suitable for bending all kind of round steel or stainless steel pipes.

Always clean up the rollers well before using stainless steel not to get the pipe contaminated.

Download (685.73 KB)

Sustarin rollers

Rollers made of Sustarin to bend round stainless steel pipes, aluminium and delicate materials with thickness not bigger than 2.5mm.

Sustarin rollers do not danage nor get the pipe contaminated.

Download (740.47 KB)

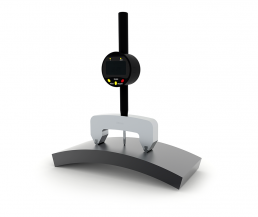

High precision digital radius gauge

Especially designed for measuring radii on profiles.

REF: 140-MED08-00001

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

The High precision digital radius gauge measures radii in spherical objects such as tubes, profiles and pipes in a quick and accurate way.

It is really fast and easy to use! It indicates the inner or outer radius of the part we are bending without removing it from the machine and without needing to previously draw and cut a guide template.

- Includes 3V CR2032 lithium battery

- Includes 3 measurement arcs (100, 200 and 300 mm).

- Supplied with a shock-resistant stainless Steel briefcase.

Included accesories for Ring roller bender section machine MC150B

Standard rollers MC150B/MC200/MC200H

It's equipped with 9 standard pieces, by means of which the user can work all kinds of profiles. Square., rectangular pipe, solid round and square bars. U Profile, T profile, angle, flat bar, edged flat bar...

Adjustable rollers. The user may combine the setup position and it will allow bending the differentprofiles, adapting the sizes.

Steel rollers F1140 treated and rectified.

Download (983.52 KB)

+ Info for Ring roller bender section machine MC150B

2 BENDING SHAPES: VERTICAL AND HORIZONTAL. The pipe bending machine MC150B can work at either upright or bent down position.

When the user has to bend any kind of profile at radius wider than 2 m or if there are height problems in the facilities, it is really uncomfortable to work vertically. It will be enough with just bending the machine down so the bending operation is made horizontally with the help of a support or stands where we place the piece in order to obtain an optimous job. Fo isntance, when we bend archs for a grrenhouse.

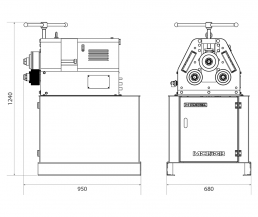

Dimensions of the machine Ring roller bender section machine MC150B

Characteristics of the packaging Ring roller bender section machine MC150B

Nº Pallets: 1.

Width: 700 mm 27,6"

Length: 950 mm 37,4"

Height: 1250 mm 49.2"

Volume: 0,83 m3

Nett weight: 270 Kg 595,3lb

Gross Weight: 280 Kg 617,3lb

Tariff Item Code: 84622900

Other features:

- Palletized bench to move the machine easily to the working site or storage.

- The machine is delivered completely mounted.

- Packaging with steel pallet and 3-layered cardboard, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine Ring roller bender section machine MC150B

The pipes and profiles bending machine Nargesa are designed to ease up the bending of different profiles and make them as comfortable as possible. The secret of bending on 50% of the profiles or pipes is in the manufacturing of the rollers. The other 50% is in the placement of the rollers for each profile or tube. The rollers for round pipes should be as tight as possible to avoid any deformation thereof. When it comes to profiles in other shapes such as flat bar, railing, square tube, rectangular, square bar, rectangular, shaped profile T, U, and angle, the positioning of the 9 rollers of the MC150B is essential for achieving a good bending job. The bending of profiles and pipes is an art that is learned with practice, however having good guidelines from the beginning helps you to progress faster. The use of this bending machine is conceived only for bending different shapes and forms, but its applications are endless: Doors, windows, railings, fences, stairs, metal furniture, sculptures, flanges for pipes, spirals pipe, greenhouses, tables chairs, traffic signs... Ideal for manufacturing of heat exchangers in copper, aluminum, brass, bronze, iron, steel... especially for bending coil heat exchangers.