The MC550CNC CNC tube bender was mass-produced with a smart control to predict radiuses, a speed variator, 4.0 technology, EcoMode, axle interpolation and the capacity to bend round pipes up to 3 inches (76.2 mm) or 80 mm 3,1".

The all-new Nargesa MC550CNC CNC pipe and profile bending machine was designed for single pieces as well as mass production. Its advanced CNC control panel makes it possible to easily create any desired geometry by directly programming the radiuses required to obtain mass-produced pieces with exceptional repetitiveness. Built with welded and machined steel sheet, the MC550CNC stands out due to its resistance and stability, perfectly adapting to applications such as the manufacture of clamps, greenhouses, railings, pergolas, windows, tables... It’s also perfect for creating urban furniture, such as streetlamps, bike racks and public transport shelters.

All Nargesa products are adapted to EC industrial machinery manufacturing standards.

Our customers say

Technical features

The Nargesa MC550CNC CNC pipe bender was designed so that any operator, even without experience, could bend pieces of all kinds with complex geometries. Finding someone who’s experienced in the world of bending is complicated and often nearly impossible. The only way is to apply new technology to the world of bending. Given the technology and quality/price ratio, the MC550CNC three-roller bending machine is considered by many government institutions, training schools, customers and manufacturers as the best 50 mm 2" axle bending option.

Smart predictive system: The all-new CNC is able to predict any desired radius right away all while avoiding material waste, thus facilitating the creation of pieces with complex geometries in just a few minutes to guarantee perfect results and optimize the production of large series.

Industry 4.0: The fourth industrial revolution is coming at the hands of Nargesa, offering complete connectivity on all of its machines for an unbeatable after-sale experience. Get free updates, professional remote technical advising, real-time diagnostics and automatic preventive maintenance warnings to enhance the machine performance and avoid problems.

EcoMode function: Automatically reduces energy consumption, disconnecting the electrical parts that consume the most during periods of inactivity. This not only minimizes energy consumption, but also reinforces Nargesa’s commitment to the sustainability of our planet and caring for the environment.

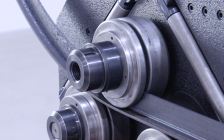

Robustness and power: Built to comply with the most demanding operating conditions, the all-new Nargesa MC550CNC 3 inch pipe bender can operate full 24-hour days without any problems. Its robustness is based on its steel sheet structure, which is thermally treated for high resistance to wear. Its power comes from an efficient reducer that transmits the movement to the axles through induction-tempered flat pinions, thus avoiding weak points.

Work in vertical and horizontal positions: The versatility of the all-new Nargesa MC550CNC 3-roller Roller makes it useful for creating small pieces as well as those with enormous radiuses. The manufacture of pieces with radiuses equal to or smaller than 750 mm 29,5" can be easily done with the bending machine, working in a vertical position. However, for larger bend radiuses, it’s best to work in a horizontal position to ensure good support and prevent the weight of the material from compromising the resulting piece. This working position is also ideal if there are any height problems at the facilities where the machine is located.

Asymmetric roller position and electronic control: Unlike pyramidal benders, the Nargesa MC550CNC asymmetric bending machine can move the two lower axles independently. This makes it possible to vary the center distances for better use of the material, which can be bent almost all the way to the ends. Likewise, the asymmetric configuration means the rollers can be practically brought together to create much smaller bend radiuses than those obtained with a pyramidal bending machine.

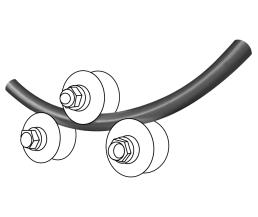

3 pull rollers: They increase the operating speed and provide the optimal material drag, which is essential when bending rectangular, square or round pipes to prevent unwanted marks on the finished product as occurs on pieces created with bending machines featuring just two pull rollers due to the need to use knurled rollers for a better hold.

Easily moved to the worksite: The hole at the top allows for movement using a crane and the lower pallet bench design means it can be moved without complicating the logistics in order to create the desired pieces in situ, thus offering better customer service and preventing continuous transfers from worksites to workshops. Plus, with a single-phase electric connection, the bending power can be available anywhere with just a standard power outlet.

Adjustable bending speed: Standard in the MC550CNC CNC pipe bender, unlike other brands, it can adapt at any time to the characteristics of the material used and optimize production without compromising the results to guarantee exceptional repetitiveness in large series as well as the creation of unique pieces in just a few minutes.

- A smart predictive system to obtain the desired radius right away.

- Easy to use: Anyone with minimal knowledge can make very complex pieces with different radiuses using the all-new CNC.

- A library with profiles, radiuses and rollers to choose from.

- Speed control and axle interpolation for perfect results and fluid transitions between segments.

- Completely automatic production, simply by pushing a button.

- A high-resolution encoder with 4096 pulses and quadrature encoder for optimal position control at all times.

- Maximum bending capacity for round tubes up to 3 inches (76.2 mm) or 80 mm.

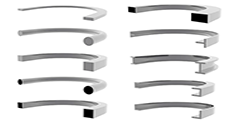

- 9 standard rollers included, which are suitable for square and rectangular pipes, for solid, UPN, IPN and T-profiles, for angles, plates and much more. Plus, optional rollers are also available for round pipes and tubes (see optional accessories in the footer).

- Outside roller diameter: 170 mm or 6.7 inches.

- Axle characteristics: Built in F154 steel, tempered and rectified.

- Diameter: 50 mm or 2 inches.

- Useful length: 90 mm or 3.5 inches.

- 3 pull rollers for a better hold and to eliminate any drag marks on the surface of the finished pieces.

- Safe transmission through tempered flat pinions, avoiding the use of chains and fragile components.

- Electro-hydraulic drive and electronic regulation independent of the position of the lower rollers to optimize the material, create smaller radiuses and provide the best results in all types of jobs.

- Adjustable roller speed: From 3 to 8 rpm, adjustable to adapt to different materials and pipe and profile sizes.

- Main motor: 1.5 kW / 2 CV.

- Hydraulic unit motor: 0.75 kW / 1 CV.

- CNC ESA S625 control panel, with a touch graphic interface.

- Voltage: 220 V single-phase.

- Palletized lower table so it can be easily moved to the working site or storage.

- Wooden pallet and 3-layered cardboard box suitable for sea freight.

- Optional: wooden packaging NIMF15.

All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are completely standard from the best European leading trademarks, with technical suppeort all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato...

Nargesa section bending machines capacity

In the PDF file you will see and download the bending capacity for Profile Formers. This are guidance sizes, it always depends a lot on the material hardness and quality of the pipe of profile.

Download (170.72 KB)

Optional accesories for MC550CNC CNC pipe bender

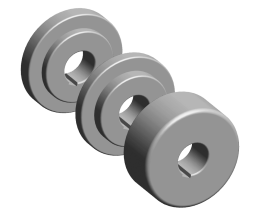

Treated steel rollers MC550

Rollers made of Steel F155 and treated to 62 Rc. Suitable for bending all kind of round steel or stainless steel pipes.

Always clean up the rollers well before using stainless steel not to get the pipe contaminated.

Download (697.01 KB)

Sustarin rollers MC550

Rollers made of Sustarin to bend round stainless steel pipes, aluminium and delicate materials with thickness not bigger than 2.5mm.

Sustarin rollers do not danage nor get the pipe contaminated.

Download (686.78 KB)

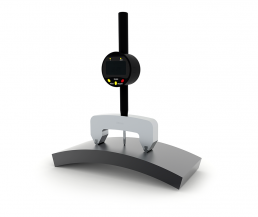

High precision digital radius gauge

Especially designed for measuring radii on profiles.

REF: 140-MED08-00001

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

The High precision digital radius gauge measures radii in spherical objects such as tubes, profiles and pipes in a quick and accurate way.

It is really fast and easy to use! It indicates the inner or outer radius of the part we are bending without removing it from the machine and without needing to previously draw and cut a guide template.

- Includes 3V CR2032 lithium battery

- Includes 3 measurement arcs (100, 200 and 300 mm).

- Supplied with a shock-resistant stainless Steel briefcase.

Included accesories for MC550CNC CNC pipe bender

MC550 Standard rollers

It's equipped with 9 standard pieces, by means of which the user can work all kinds of profiles. Square, rectangular pipe, solid round and square bars, U Profile, T profile, angle, flat bar, edged flat bar...

Adjustable rollers, by washers with the size of profile or pipe which allows us to make bending to different pipe or profile sizes.

Steel rollers F155 treated and rectified.

Download (1.67 MB)

+ Info for MC550CNC CNC pipe bender

CHARACTERISTICS OF THE CNC ESA S625 CONTROL

The CNC ESA S625 control panel which comes standard with the Nargesa MC550CNC CNC pipe bender features total connectivity to comply with the requirements of the industry 4.0 as well as a 7 inch color touchscreen, which combines processing power with an intuitive, easy-to-use graphic interface. With step-by-step digital programming modes, creating a unique piece or large series based on the initial concept is super fast and easy: define the type of tube or profile, the dimensions, the material and the axle roller configuration, and then ask the control for the desired radiuses. After that, you just have to press a button to get excellent results.

These are some of the most relevant features of this control system.

- A smart predictive system to obtain the desired radiuses right away.

- Storage capacity for more than 10,000 programs in step-by-step, digital mode.

- Interpolated axle control with independent speed adjustment for soft transitions on perfect pieces without any marks.

- Configuration of measurements in inches and millimeters.

- A database with the available rollers, featuring addition and editing options.

- A database for profiles, pipes and materials, featuring addition and editing options.

- A multilingual interface with a display in more than 20 different languages.

- Adjustable bending speeds of between 3 and 8 rpm for optimal results.

- Manual or automatic operating mode.

- Total connectivity to meet the requirements of industry 4.0 and receive remote technical advising and assistance anywhere in the world.

- A 4-way joystick for rotation movements and positioning in manual model, and step-by-step programming.

- Digital programming to more easily create the first piece.

- A button with an indicator light for mass production.

- On-screen alarm and status diagnostics.

- Real-time warnings for preventive maintenance.

- 800x480 pixel screen graphic resolution.

- SSD storage disc with 128 MB capacity.

- 2 analog inputs with a 12 bit ADC converter.

- 16 digital inputs (24 Vdc).

- 16 digital outputs (24 Vdc, 0.7 A max.), protected against overloads and short circuits.

- Up to 3 differential encoder inputs with a TTL interface and optional external power.

- 1 RS232 serial port with a standard DB9 connector.

- 1 CAN port with a standard DB9 connector.

- 24 Vdc supply voltage.

- 1 USB port.

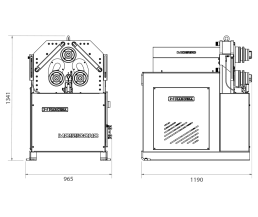

Dimensions of the machine MC550CNC CNC pipe bender

Characteristics of the packaging MC550CNC CNC pipe bender

Nº Pallets: 1.

Width: 1380 mm 54,3"

Length: 1070 mm 42,1"

Height: 2090 mm 82,3"

Volume: 3,08 m3

Nett weight: 883 Kg 1946,7lb

Gross weight: 925 Kg 2039,3lb

Tariff Item Code: 84622900

Other Features:

- Palletized bench to transport the machine easily to the working place or storage.

- The machine is sent completely mounted.

- Packaging with wooden pallet and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

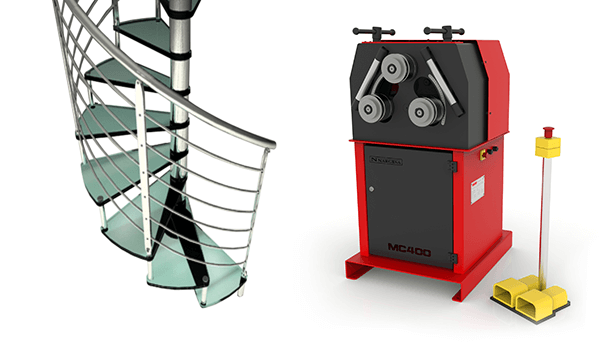

Uses of the machine MC550CNC CNC pipe bender

Versatility and immense bending capacity are the two main characteristics offered by the NARGESA MC550CNC pipe bending machine. The robust design and operating power make it possible to bend all types of profiles problem-free, such as UPN, IPN and T-profiles, angles, flat and edged plates, solid sheets and tubes, whether they are round, square or rectangular, and much more. The range of applications for which it is ideal include the creation of large architectural and construction structures to urban furniture. It’s specially recommended for manufacturing circular beams for roofs and domes, stirrups for bridges, curved shelters for public transportation stops as well as designer pergolas in addition to structures for greenhouses, clamps, streetlights, roundabout protections, fencing and other protective devices, bike racks, bollards, piles, benches, tables, chairs, windows, doors, plumbing piping, curved railings for balconies or staircases, metal structures for ceilings, curved rebar for construction work, furniture such as shelves and chair frames, metal arches for bridges, curved metal canopies, lamp bases, staircase rails, support structures for solar power systems or photovoltaic panels, custom vehicle chassis, curved paths for vehicles in work areas, bent architectural elements such as entryway arches, curved profiles for carpentry, pedestrian bridges made of metal and much more.

And it’s not just great for structures with large radiuses, as it is also useful for shaping small profiles, tubes and pipes, all without needing to use any more rollers than the nine supplied standard with the bending machine. They’re useful for most profiles and pipes available on the global market, both in millimeters and inches. And due to its design, it is particularly suitable for producing heat exchangers and reels of materials ranging from copper to aluminum, tin, bronze, iron and steel. Considering all of this, the Nargesa MC550CNC is no doubt much more than just a bending machine: it’s a complete solution for any roller project and ideal for those looking for productivity, precision and new business opportunities.