Buying a profile and section bending machine

If you're looking for a tube and profile bending machine for your business, at Prada Nargesa we are considered one of the best manufacturers of tube and profile benders, both for the quality of our products and for our prices and experience. Here, we explain the steps to follow when choosing an industrial bending machine. Learn what to consider before choosing a tube and profile roller from the range of Nargesa industrial machinery: Ring Roller Bender Section Machine MC150B, Ring Roller Bender Section Machine MC200, Profile Bending Machine Machine MC400, Hydraulic Section Bending Machine MC200H, Section and Tube Bending Machine MC550, and Section and Pipe Bending Machine MC650.

Know the type of work and maximum tube diameter

We must know exactly what work we will perform with the bender. It is important to know what types of profiles and pipes we will bend. To choose the most suitable machine, it is necessary to know the maximum diameter in round pipe, tube, or profile that we will bend. This will determine the size of the machine we need to buy. Often, the machine's capacity depends on the shaft's dimension. For example, a pipe roller with an 80mm shaft can bend a tube with a maximum diameter of 80mm under normal conditions, except for the smaller ones with a 40mm shaft that can bend tubes up to 2.5 inches (63.5mm). It is important to know the diameters of all the shafts, not just the upper one.

The prices of tube benders can vary depending on the diameter

The price difference between benders of different diameters is very high when we need a bending machine for tubes over 2.5 inches. The prices of a pipe roller of 1 inch, 2 inches, up to 2.5 inches, are very similar, but beyond 2.5 inches the price increase is considerable.

Two-roller drive or three-roller drive?

If the work we will perform is occasional and the finish is not very important, we can work with a machine where only two shafts are motorized. Keep in mind that benders with two driving rollers must have knurled rollers to help drive the material. Note that only the two lower shafts have drive power, the upper shaft does not. When bending square profiles and tubes with this type of bender, the corner of the material in contact with the two lower rollers always gets marked. Our recommendation is that if you need to bend a round tube, use a bender with three motorized rollers. This way, you avoid drive problems. With only 2 driving rollers, the roller slips and prevents the work from being as fast as with 3.

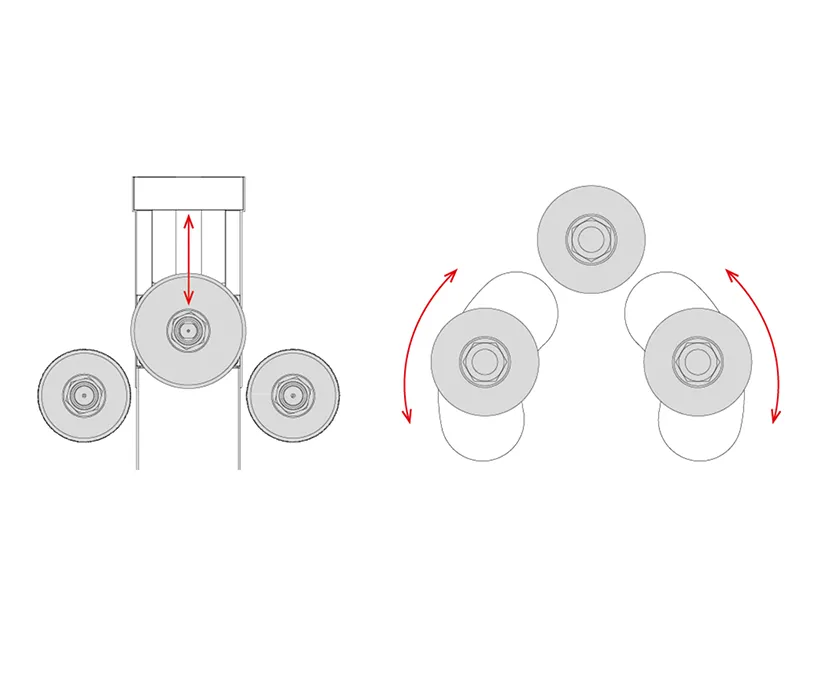

Which industrial bender suits you best: pyramid bender or asymmetric bender

The pyramid bender is easy to recognize: only the upper and central roller moves up and down. It can be manual via a lever or hydraulic piston. The asymmetric bender, on the other hand, allows the two side rollers to move to determine the bending diameter.

The pyramid bender can have either a 2-roller drive on the lower rollers or a 3-roller drive. It is easier to roll large-diameter tubes because the distance between the centers of the lower rollers is much greater and always fixed compared to asymmetric benders. If you need to bend large-diameter profiles most of the time, this system is a good option. Conversely, if the work varies and sometimes requires very small bending diameters, the best option is an asymmetric profile and tube bender, as the distance between the rollers varies until the lower rollers can touch the upper roller, allowing for the smallest bending diameters. This bending system makes better use of the material by having the rollers closer together. At Prada Nargesa, we consider the asymmetric bender to be much more versatile, efficient, and faster than the pyramid bender.

Mechanical considerations for choosing a profile bender

Knowing the material the shafts are made of helps us understand their elasticity. Never buy a bender where the shafts are not tempered and ground. Ideally, they should be made of D2 steel or its equivalents. These will allow the bender to handle overstrains without the risk of shaft breakage.

The drive of the pipe bender is very important

There are different drive systems. The best solution is drive via induction-hardened gears, as there is no loss of effectiveness throughout the roller's life. In the case of those using gears and chain, it is important to know that over time the chain stretches and the machine often becomes inefficient. Other benders use a cardan system with a plastic safety device for overstrains. This breaks when trying to bend a profile too much or too quickly. Another system, in higher-capacity bending machines, uses hydraulic motors and induction-hardened gears, similar to the gearmotor with hardened gears and equally effective. Considering these mechanical aspects is very important, as although some machines may be initially cheaper, they end up being more expensive and unsustainable.

Should you choose a vertical or horizontal roller bender?

This choice is straightforward. Sometimes, choosing one over the other is determined by the height of our facilities. If we need to bend a tube with a 4-meter diameter and our workshop doesn't have that height, when buying a bender we should choose a horizontal position bender. If we need to bend large diameters, a horizontal position is preferable, with roller supports or roller paths at both ends of the bender to facilitate bending work. Benders up to 2.5 inches or 40mm shafts are usually vertical. It's a more convenient way to bend all profiles. For machines with 60mm shafts or larger, they are typically designed to be placed in both positions, although it always depends on the profile to be bent.

How should the chassis of a pipe bender be?

Currently, almost no manufacturer uses cast iron chassis. Never buy a tube and profile bender with a cast iron chassis if you want to perform professional and guaranteed work. Under any overstrain, it can crack without detection. The bender body should be made of welded iron and properly machined afterward, after a prudent stabilization period.

What bearings should a tube and profile bender have to be more durable?

Avoid benders with conventional ball bearings. Modern benders use tapered bearings, which are much more durable and reliable.

Can an iron bender bend aluminum?

In most cases, iron benders are only for bending iron and aluminum benders for bending aluminum. For good bending of iron profiles, it is important that the shaft centers are as close as possible. Unlike aluminum benders, which have much more spaced and often adjustable shafts. If the aluminum profile is small or simple, you can ask the manufacturer if it's feasible, always indicating the minimum diameter you want to bend the aluminum profile. Most aluminum profiles are filled with fine sand or marble powder. They vibrate it, and finally, the profile is ready to be bent. Only in this way can many aluminum profiles be rolled.

What warranty does a tube and profile bender have?

The manufacturer's warranty is another factor that helps us choose one brand over another. By law, depending on the country, the warranty for profile bending machines is usually one year. At Prada Nargesa, we provide a 3-year warranty on our bender models: (Ring Roller Bender Section Machine MC150B, Ring Roller Bender Section Machine MC200, Profile Bending Machine Machine MC400, Hydraulic Section Bending Machine MC200H, Section and Tube Bending Machine MC550, and Section and Pipe Bending Machine MC650).

Emerging technologies: ESA control

The Nargesa MC550 and MC650 benders feature advanced control with a 7-inch color touch screen, very intuitive and easy to use, equipped with the latest 4.0 technology. When making the first piece, each step can be saved for the control to automatically repeat these operations on subsequent pieces, without needing to control longitudinal positioning. The program also allows storing information about the type and size of the tube or profile, material, and roller settings for future series, among other functionalities.

Sustainability

At Nargesa, we understand the crucial importance of energy savings today. Therefore, our new MC550 and MC650 machines incorporate the innovative EcoMode, a feature that automatically disconnects the highest consumption electrical parts during inactivity periods, allowing significant energy savings. When resuming production, just press a button, making the process not only efficient but also environmentally friendly. This feature not only contributes to our customers' savings but also reflects our firm commitment to sustainability and planet protection. At Nargesa, we believe that every small technological advancement can have a big impact on environmental sustainability.

Safety considerations

It's crucial to comply with safety procedures and regulations related to the use of bending machines. Essential safety features include emergency stop systems and overload protection. The use of personal protective equipment (PPE) is also indispensable to ensure operator safety.

Maintenance and durability

To ensure the longevity and efficiency of the bender, it's essential to follow preventive maintenance routines, such as regular cleaning and proper lubrication. The expected lifespan of the machines and their key components, as well as the availability and cost of spare parts, are important factors to consider.

Training and after-sales support

The availability of training for operators and technicians, as well as the quality and accessibility of the after-sales support offered by manufacturers, are key factors that can influence your decision. Good after-sales support ensures that any issues can be resolved quickly and efficiently.

Leave a comment

Join to our Newsletter

Be part of our Nargesa Community and get all information of the branch, demo clips, campaigns in Machinery…

Comments

Bending

Samuel perez - Fri, 09/16/2016

I want to bay a nargesa bending machine with everything

buying a MC650 - Nargesa

Gangadhar Maru… - Tue, 09/27/2016

I am intending in buying a MC650 - Nargesa with all accessories . kindling forwad me the qoutation and time of delivery onces the order is confirmed

Buying MC650

Awadh Ahmed - Sat, 04/01/2017

I will lke to buy MC650 please let me know CIF to Dar-es-Salaam Tanzania please.

Cheers

Awadh

MC650-NARGESA

John - Fri, 04/07/2017

I WANT TO BUY THIS THINGS

mc 150b price

polpoj polchar… - Sun, 10/02/2016

I am intending in buying a MC 150b with all accessorries .please kinding to sent me the price by e-mail.

Quotation

Sushanta kundu - Mon, 11/07/2016

I am from India kindly quote me the price of mc150 with all types of rollers

Thank you.

please send me your price

marlon - Mon, 10/03/2016

please send me your price list for bending machines.

pricing

Bob Wilt - Tue, 10/18/2016

How can I get pricing quote on the mc150 bender

About prise of mc 150 b

Asela madusanka - Mon, 11/14/2016

Hi I would like to know prise of MC150 B with all of accosery ? For Dubai

MC150B price

Justin Herrera - Sat, 12/03/2016

Hi could you please send me a price on this machine MC150B and could you also include shipping to the U.S. in San Diego

Quotation

Anil kumar - Wed, 12/07/2016

Could you please send a quotation of this machine MC150 B and also include shipping to the India

Thanks

Hi I want to bay a nargesa

ashraf kapoor - Sun, 12/11/2016

Hi I want to bay a nargesa bending machine plz send me your price list and include shipping to the india

Mc 150d price in Indian

shaik ismail - Mon, 01/30/2017

Mc 150d price in Indian rupees

price

anees rahman - Sat, 03/11/2017

sir, iwant MC150B NARGESA price

Hi I want to bay a nargesa

Deepak - Tue, 02/21/2017

Hi I want to bay a nargesa bending machine plz send me your price list and include shipping to the india kerala.

Bending Machine

David Kabengule - Tue, 12/27/2016

I need your quotion for MC150B NARGESA bender. Also advise i need it for stationing at the workshop and do bending metal for various purposes. Handling Mild steel, Stainless steel aluminium e.t.c

Quotation

JOSEPH DEVLIN - Sun, 01/29/2017

Hi I am after a quotation on your rolling machining. Possibly mc150.I wish to bend polished stainless steel 1.2mm wall. Will this be possible? I intend to make polished bars for lorries etc so I would need to be fit to bend up to 2 1/2". Could you quote and advise the best option for me and do I need different size dies to bend different diameters pipe. Thanks

HI! please send me your price

aleksander - Sun, 02/05/2017

HI! please send me your price list for bending machines whith accsessories,and shipping to Latvia,Riga.thank's!

mc150 b

joko budi raharjo - Sat, 03/25/2017

I am very interested in your product, but how can I get it

MC 650 and MCH 400

Awadh Ahmed - Sat, 04/01/2017

Hi

Please let me know the price of that two Machine as subject above,

Cheers

Awadh

Mc150B

Ian Gillett - Sun, 05/14/2017

I would like a price please, on a Nargesa Mc150B.

Machine price?

Pratik chichkoti - Sun, 05/21/2017

I want to buy the machine ,what is its cost

Machine price?

Pratik chichkoti - Sun, 05/21/2017

I want to buy the machine ,what is its cost

ms pipe bending

savan - Sun, 05/21/2017

Nargesa pipe bending machine price in India gujrat pin:384315

mod. mc150b

purchase price

Steve Young - Thu, 06/15/2017

Hi to all could you provide an estimated cost of the MC150B bending machine capable of performing all of the actions shown on your tutorial. could you also provide freight cost in total.

Thanks for your time Steve

mc 150B nargesa

Kritivas badtiya - Sat, 07/01/2017

please send me your bending maching price.

Banding machine

Santosh sharma - Mon, 08/21/2017

Nargesa banding machine

I am menufacturer of Furniture and we need banding machine

Please send price small size banding machine price

Machine price enquiry

Prashanth jain - Tue, 10/17/2017

I am from India I want buy bending machine pls contact me 919900927921

Quote

Buyer - Fri, 11/17/2017

What's the price for mc 150 bender

I want to bent stainless steel tubes from 7/8 to 11/4 dia tubes.n metric equivalent

Thank you.k1tp5

QUOTE

Mariana - Fri, 01/12/2018

Hi, could you please tell me the price of the MC650 in the US?

Nargesa MC 150b

Daniel - Tue, 01/30/2018

Salut cat costa MC150B transport in Romania,EU locuiesc acum in Irlanda,va multumesc Daniele

MC 150B

Edgardo Aves - Sun, 02/18/2018

Please send me the price of MC150 B with all bending options to all metal profiles, like: flat bar, angular, round bar, and tabular profile, square tubing and rectangular..

MC 150B

Edgardo Aves - Sun, 02/18/2018

Price if ship to FILIPINAS

Mt500a

Jerome - Mon, 10/22/2018

Do you deliver to philippines/filipinas.how much this machine mt500a and cost of deliver in manila.thank u. Please reply

REPLY: Mt500a

Nargesa - Mon, 10/22/2018

Hello Jerome. We arrange shipment anywhere in the world. Our sales department will send you a quotation as soon as possible