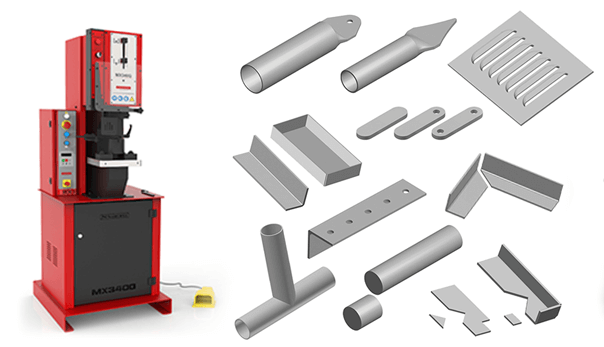

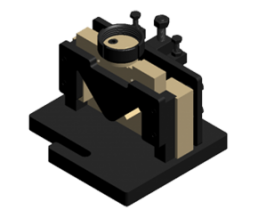

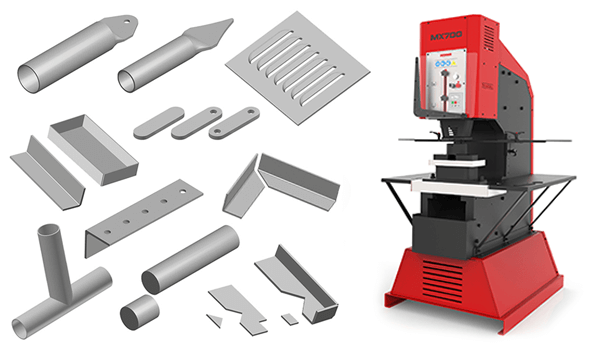

All purpose ironworker machine MX340G NARGESA more than 40 tons. Its neck, displacement and wide working table turn it into a very versatile tooling: It pierces, folds, cuts, inlays, etc...

The Hydraulic Punching machine MX340G NARGESA, is characterized by its versatility, it can make several working functions like punching in metal sheet, flat bar, pipe, angle, U profile, T profile, UPN, IPN... Bending, Cutting, inlaying, punching, pipe notching tube, embossing... it can be adapted any kind of tooling, even one made by the customer himself. Its versatility and easy use, makes it an essential item for a metal working workshop.

All products Nargesa are according to the European CE normatives and regulations for the manufacturing of industrial machinery.

Our customers say

Technical features

- Hydraulic power: 40 Tn.

- Working speed: 7,1 mm/sec.

- Return speed: 9,3 mm/sec.

- Punch displacement: 100 mm.

- Neck: 180 mm.

- Table Dimensions 245x265 mm.

- Swinging front safety protection.

- Activation with safety pedal.

- Digital display.

- Parts and strokes counter.

- Alarm diagnose.

- Motor power: 2,2 KW/ 3 HP.

- Tension 3 phase: 230/400 V.

- For other tensions or single-phased machines ask the manufacturer.

- Palletized lower bench to move it easily to the working site or storage.

- The machine is delivered completely mounted.

- Packaging with steel pallet and 3-layered cardboard box suitable for sea freight.

- Optional: Complete fumigated wooden packaging NIMF15.

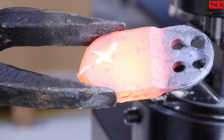

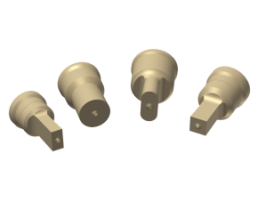

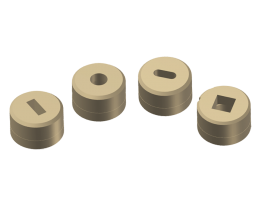

PUNCHING:

All kinds of punches can be supplied: round ones, square, oval, locks punches... Punching can be also made in a pipe.

OTHER APPLICATIONS:

There are a lot more applications for it. More than 40 standard tooling to make different jobs. (See OPTIONAL TOOLING, at the bottom of the page).

NO STANDARD APPLICATIONS:

If the customer requires it we can manufacture under-request tooling to make all kinds of parts.

ADVANTAGES:

- It is different from the rest of the other multifunctional universal punching machines because of its 180mm gooseneck, 100mm displacement and wide working table that allows to fit any kind of tooling. Many of our customers make their own tooling.

- Fast change of tooling, max. 30 seconds.

- Displacement adjustment allows an increase on productivity.

- There is no maximum dimension for punching.

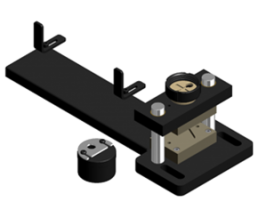

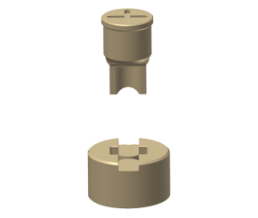

STANDARD EQUIPEMENT PROVIDED WITH THE MACHINE:

All Nargesa Hydraulic Punching Machines are equipped with the punching tool that include the fitting nut for punches and the base holder for dies. The rest of accesories are optional, which means each customer equips his machine as desired.

All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are all standard from the best leading European trademarks with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Calculation of punching capacity

In the PDF file we will show you how to calculate the punching capacity for the different thicknesses, materials and shapes... What thicknesses can be punched and with which punch diameter. Ideas and suggestions to improve jobs performance and increase punching capacity.

Download (1.77 MB)

Optional accesories for Hydraulic Punching and Shearing Machine MX340G

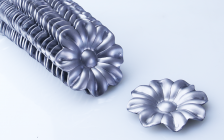

Round punches and dies, square punches, oval punches, rectangular, Nargesa

In Nargesa we have a wide catalog of punches and dies of all kinds. If the size the customer needs is not in the list, we can make it. In the PDF file you could see all the sizes we have.

Download (931.24 KB)

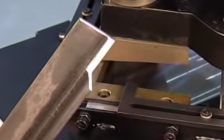

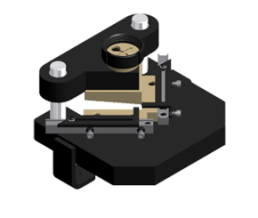

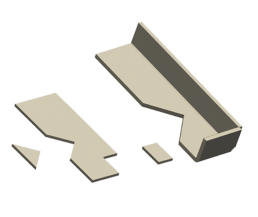

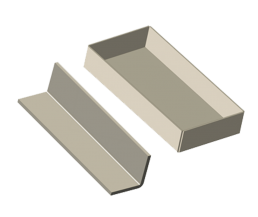

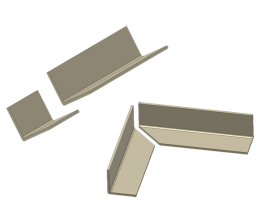

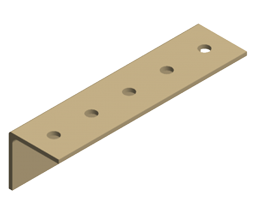

Stripper tooling 90º adjustable 100x100

Sheet stripping tooling, angle etc. adjustable up to 100x100mm to 90º fix.

REF: 140-02-01-00005

MAX. CUTTING CAPACITY: 100x100x4mm

WEIGHT: 35 Kg.

Optional Tooling.

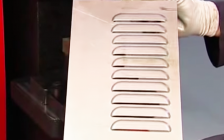

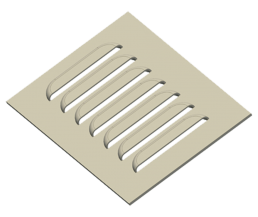

Ventilation grill tooling

REF: 140-02-01-00010

PUNCHING SIZES: 100X20mm.

MAX. THICKNESS: 2mm.

WEIGHT:20 Kg.

Optional Tooling.

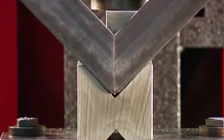

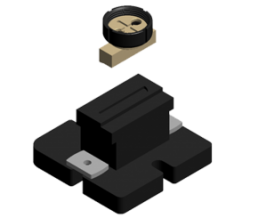

Folding tooling 170mm.

REF: 140-02-01-00004

MAX. FOLDING LENGTH: 170mm.

MAX. FOLDING THICKNESS: 8 to 12mm.

WEIGHT: 12 Kg.

Optional tooling.

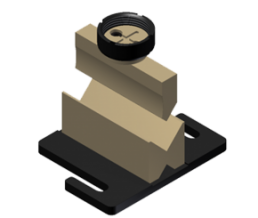

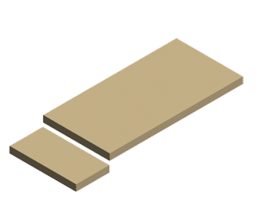

Flat bar cutting tooling 100x10mm.

REF: 140-02-01-00002

MAX. CUTTING CAPACITY: 100x10mm.

WEIGHT: 28 Kg.

Optional Tooling.

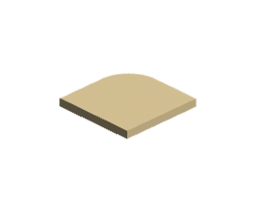

Tooling to round off corners

Tooling to round off the corners in metals sheets of different radius. In the PDF file you will be able to see all kinds we have.

Download (597.81 KB)

Flattening extractor

REF: 140-02-01-00039

MAX. THICKNESS FOR FLAT BAR OR SOLID BAR: 15mm.

WEIGHT:15 Kg.

Optional Tooling

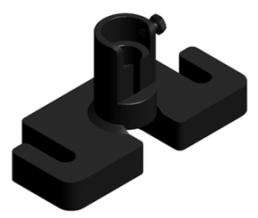

Angle cutting tooling

REF: 140-02-01-00001

MAX STRAIGHT CUTTING CAPACITY: 60x60mm

MAX.MITRE CUTTING CAPACITY: 50x50

WEIGHT: 32Kg.

Optional tooling

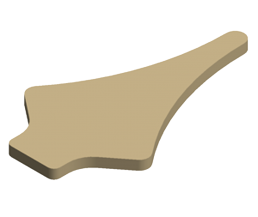

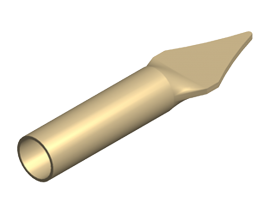

Arrow tooling for metal sheet

REF: 140-02-01-00006

MAX. SHEET THICKNESS: 3mm

WEIGHT:21 Kg.

Optional Tooling.

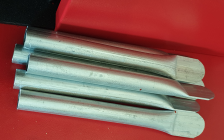

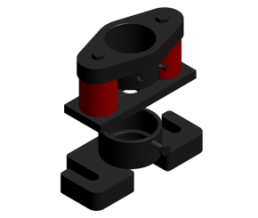

Arrows tooling for pipes

REF: 140-02-01-00007

MAX. PIPE DIAMETER: 30x2mm

MIN. PIPE DIAMETER: 10x2mm

WEIGHT:19 Kg.

Optional Tooling.

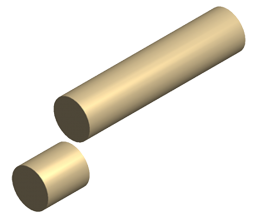

Round bar cutting tooling

REF: 140-02-01-00035

MAX. CUTTING DIAMETER: 35mm.

MIN. CUTTING DIAMETER: 3mm.

WEIGHT:15 Kg.

Optional Tooling

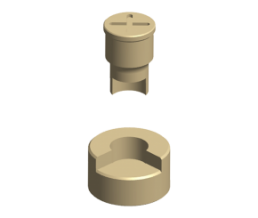

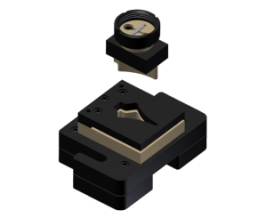

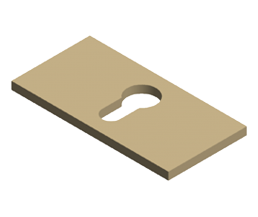

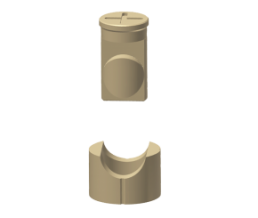

Punch and die for locks

Necessary complements: CAB60 and TAP40

REF: 140-02-01-00036

MAX. THICKNESS: 6mm

WEIGHT:1 Kg.

Optional tooling.

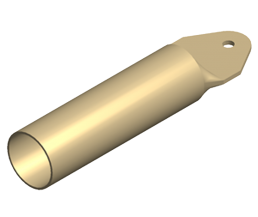

Pipe ends fencing tooling

REF: 140-02-01-00040

MAX PIPE DIAMETER: 50mm

MIN. PIPE DIAMETER: 10mm

HOLE DIAMETER: Intercambiable.

WEIGHT: 23 Kg.

Optional Tooling

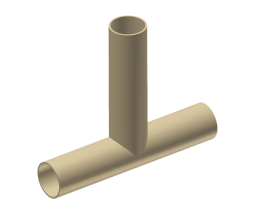

Pipe notching tooling

Pipe notching tooling from Ø16 to Ø60mm. It consists of cutting the extreme of a pipe so it can be joined to another one perpendicularly. In the PDF file you will be able to see all kinds and sizes we have.

Download (597.81 KB)

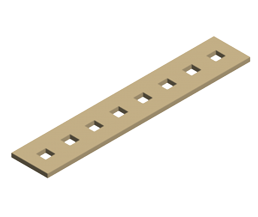

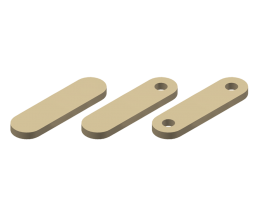

Flat bar round end tooling

Tooling to make all kinds of flat bars with round ends, with or without hole, straight, round...Very used as handles, stands, etc... Starting from a metal strip, a piece with the desired length comes out of it with every stroke. In the PDF file you will see all kinds of shapes and sizes we have.

Download (534.46 KB)

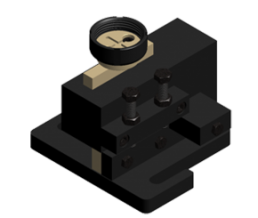

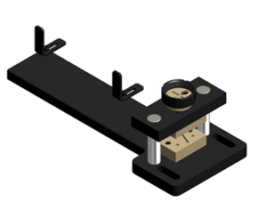

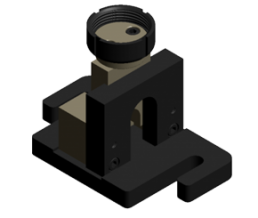

Included accesories for Hydraulic Punching and Shearing Machine MX340G

Fitting nut for punches and base holder for dies MX340

Download (558.69 KB)

+ Info for Hydraulic Punching and Shearing Machine MX340G

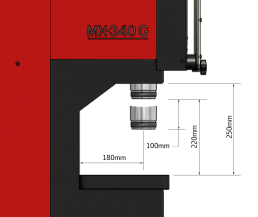

Hydraulic Punching Machine MX340G is different from the other ones because of its long displacement and working gooseneck that allows it to be adapted a number of dies and tooling. Its versatility and features makes it a fast payback machine. It carries out the same functions of 5 different machines.

- Gooseneck (Neck): 180 mm.

- Piston displacement: 100 mm.

- Mx. Height. : 220 mm.

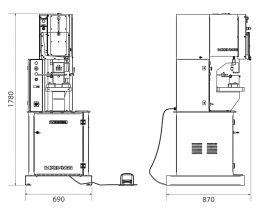

Dimensions of the machine Hydraulic Punching and Shearing Machine MX340G

Characteristics of the packaging Hydraulic Punching and Shearing Machine MX340G

Nº Pallets: 1.

Width: 700 mm.

Length: 800 mm.

Height: 1800 mm.

Volume: 1 m3

Nett weight: 615 Kg.

Gross Weight: 635 Kg.

Tariff Item Code: 84624900

Other features:

- Palletized bench to move the machine easily to the working site or storage.

- The machine is delivered completely mounted.

- Packaging with steel pallet and 3-layered cardboard, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine Hydraulic Punching and Shearing Machine MX340G

The Hydraulic Punching Machine Nargesa MX340G can punch any kind of profile: Flat bar, steel sheet, Pipe, angle, UPN, U profile, T profile, IPN, etc... They can be fit different tooling for tube notching, stripping metal sheet, fabricate arrow ending in steel sheet and pipes, roud up steel sheet corners. They can be fitted any kind of tooling made by the customer himself or bought from any other manufacturers.