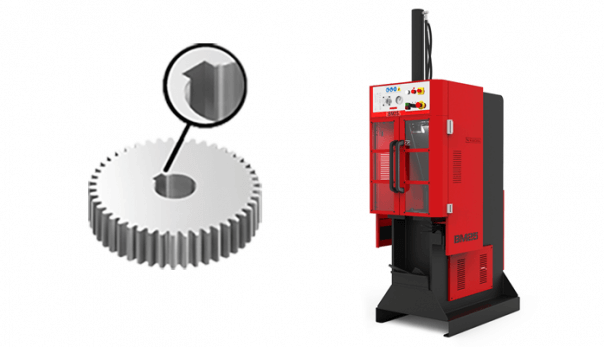

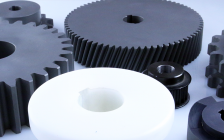

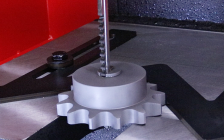

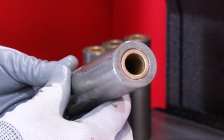

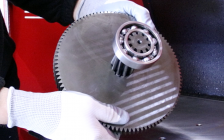

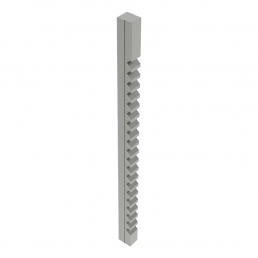

The Hydraulic Broaching machines BM25 NARGESA is a machine to make notches or keyways in all kind of pieces: sprockets, pulleys, gears, bearings...

Internal keyway broaching machine BM25 NARGESA has been fabricated in a welded and mechanized steel monoblock. It's a machine useful for making notches and keyways in all kinds of pieces: sprockets, pulleys, gears...

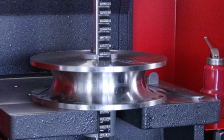

It is also used like a press to unbolt oxidated parts, assembling and dismantling bearings...

Our customers say

Technical features

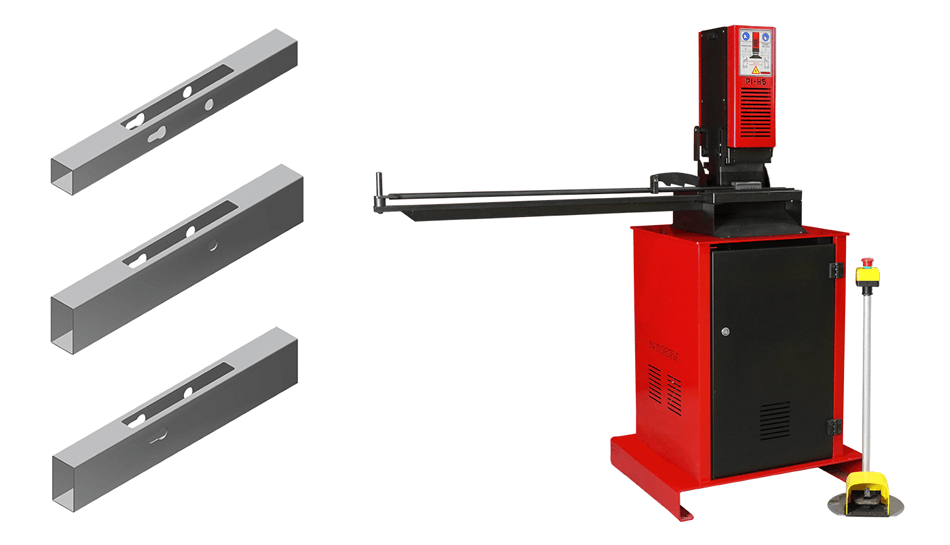

The Vertical slotting machine BM25, has been thought for small medium productions, it is characterized by its great versatility, reliability, easy use, fast setting up and effectiveness:

- Versatility: It’s used for making small and big pieces. All kinds of broaching and different tolerances. 2 mm keyways from 2 up to 25mm or 1” inch. It is also used like a press to unbolt oxidated parts, assembling and dismantling bearings...

- Reliability: Because of its use, the keyway is always made with the required tolerance and parallelism.

- Easy use: Anyone can make a keyway, ther’s no need to be a skillful operative.

- Fast setting up: The preparation time of the machine before making a broaching operation is approximately 1 min.

- Effectiveness: The machine can be moved easily next to a lathe or machining center. While those machines work, the same operative can make the broaching operation.

Structure

- Mechanized single-block bench

- Lower bench palletized to move the machine easily to the working site or storage.

- LED front lightning.

- Manual operation for a better broaching control.

- Low noise level which improves the working quality of the operator.

- Front polycarbonate protection that allows to see the broaching process.

- Front opening with safety hinges.

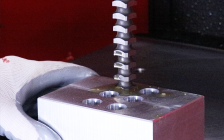

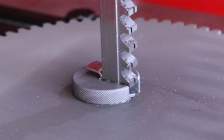

- Tooling supplied as standard for the positioning of the parts. This tool is adjusted and fixed to the work bench in the exact position so that the broaching piece is placed easily and quickly in its correct position. There is no need to hold the piece.

- Hydraulic oil CEPSA HYDRAULIC HM 68

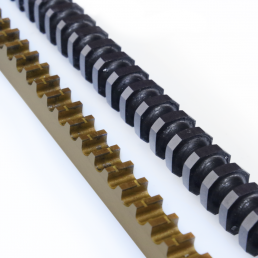

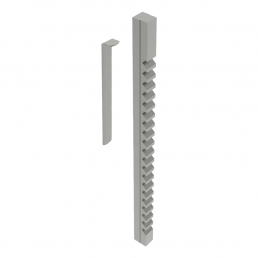

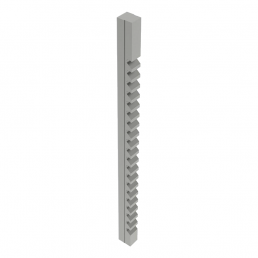

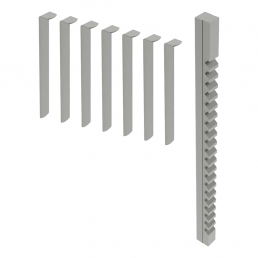

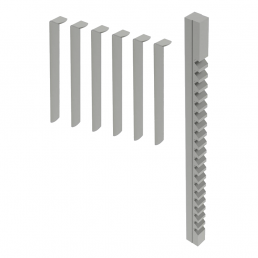

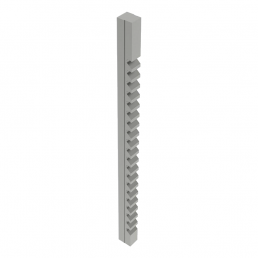

Broaches

- The broaches we offer are one of the best trademarks in the market, internationally speaking.

- They are manufactured under strict quality controls, guaranteing the higher liability and durability.

- Made in the USA.

- Some shims are provided with each broach, the ones used for accomplising the required tolerance.

- Broaches in millimeters and inches.

- Broaches of different kinds and tolerances: ISO J-9, ISO P-9.

Control panel

- The control panel is very intuitive and easy to use.

- It includes the conversion chart from pressure to tons.

- Broaching pressure regulator with pressure manometer.

Safety

- The Broaching machine BM25 incorporates all safety devices according to CE regulations.

DETAILED FEATURES

- Neck: The 300mm neck allows to broach pieces up to 600mm in diameter, without any problem.

- Front polycarbonate guards: The two front doors incorporate polycarbonate windows so that the operator can control the broaching process at all times, in total safety.

- Lighting on the broaching table: It is very important to count on a proper lighting inside the broaching cabin, so the operator can control the whole broaching process.

- Drawer for chips collection: The machine has a drawer where all the chip that is generated during the broaching process is collected. This is a removable drawer which can be easily emptied.

- Pressure regulator: By using the pressure regulator and the pressure manometer installed in the machine, we can adjust the working pressure so that it is the ideal one for each broaching operation.

The broaches we offer are one of the best trademarks in the market, internationally speaking. They are manufactured under strict quality controls, guaranteing the higher liability and durability, Made in the USA. Some shims are provided with each broach, the ones used for accomplishing the required tolerance.

- Broaches in millimeters and inches.

- Broaches of different kinds and tolerances: ISO J-9, ISO P-9.

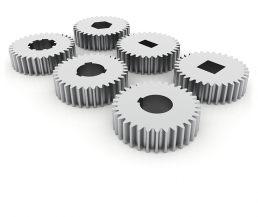

CHARACTERISTICS OF THE MACHINE

- Motor power: 2,2 Kw / 3 Hp.

- 3-phased tension: 230/400 V.

- Hydraulic power: 10 Tn.

- Max. broaching capacity: 25 mm.

- Working speed: 24 mm/s.

- Return speed: 54 mm/s.

- Pump Flow: 7,5 liters.

- Capacity of Hydraulic Tank: 25 liters

- Shank displacement: 600 mm.

- Goosneck: 300 mm.

- Max. piece diameter: 600 mm (For different sizes, please ask the manufacturer)

- Bench dimensions: 420 mm x 420 mm.

Packing with steel pallet and retractile film

Optional: Complete wooden packing NIMF15

Its versatility, reliability, productivity and easy handling make it one of the best machines for a maintenance workshop or medium production factory. By medium production we mean less than 350 units.

All our products are manufactured in our facilities in Spain. Hydraulic and electronic components are completely standard from the best European leading trademarks, with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato...

All Nargesa products are according to the CE normative and regulations for manufacturing industrial machinery.

How to broach and calculation of guide bushes

In the attached PDF file we'll show you how the steps to follow in order to carry out a correct broaching operation. Taking pictures as samples, we will present the different accessories and its correct use. Besides you will find the necessary information to manufacture the guide bushes according to the diameter and the broach.

Download (172.48 KB)

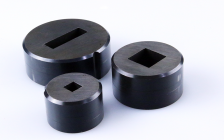

Optional accesories for Vertical Broaching Machines BM25

Keyway broaches with special coating and different shapes

Keyway broaches of different shapes

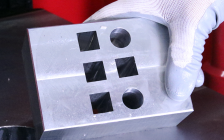

Keyway broaches to make slots of different polygonal shapes: squares, rectangles, hexagons...

Keyway broaches with special coating

Keyway broaches with TiN and TiAIN coating are supplied with the most common American standard (1/16“- 1”) and metric sizes (2mm - 25mm).

The coatings provides greater performance through high lubricity and hardness, which allows greater production in their most demanding materials. The keyway broaches are supplied with the necessary shims.

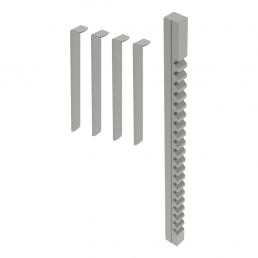

Bushings for broaching

F114 steel guide bushes in H8 diameter tolerance to optimize the perfect finish of the part.

Download (385.05 KB)

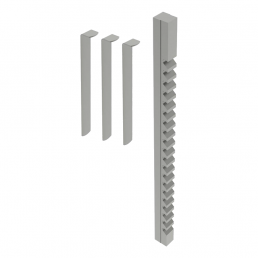

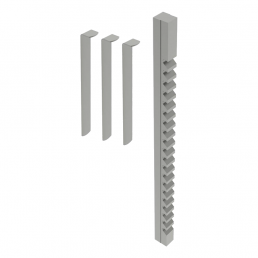

Keyway broaches 25mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00017

Broaching time: 5:00 min.

Tolerance: JS9 (-0,027 +0,013)

Model: F

Broach dimensions: 25,40 x 514,35mm

Standard keys: 25 x 14mm

Tooth pitch: 15,875mm

No. of Teeth: 26

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 12.300Ibs

Required pressure: 5.579,18Kg

Shims

Required shims: 4 units

Number of passes: 5

Thickness: 1,422mm

Bushings

Bushing diameter: 75, 80, 85, 90, 95, 100, 105, 110, 115 and 120mm

Bushing length: 152,4mm

Weight: 3,5 Kg. Approx.

Optional Tooling

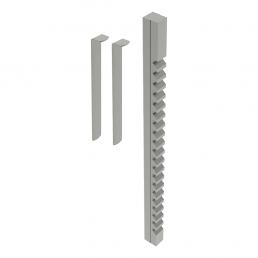

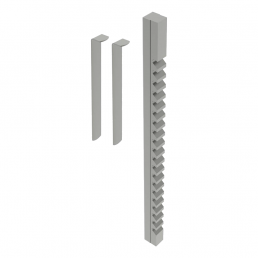

Keyway broaches 24mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00016

Broaching time: 5:00 min.

Tolerance: JS9 (-0,025 +0,015)

Model: F

Broach dimensions: 25,40 x 514,35mm

Standard keys: 24 x 14mm

Tooth pitch: 15,875mm

No. of Teeth: 26

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 10.600Ibs

Required pressure: 4.808,07Kg

Shims

Required shims: 4 units

Number of passes: 5

Thickness: 1,587mm

Bushings

Bushing diameter: 75, 80, 85, 90, 95, 100, 105, 110, 115 and 120mm

Bushing length: 152,4mm

Weight: 3,5 Kg. Approx.

Optional Tooling

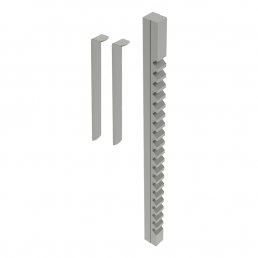

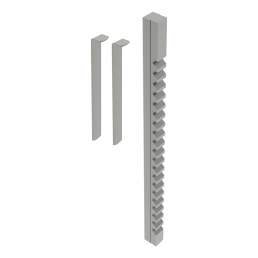

Keyway broaches 22mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00015

Broaching time: 5:00 min.

Tolerance: JS9 (-0,027 +0,014)

Model: F

Broach dimensions: 25,40 x 514,35mm

Standard keys: 22 x 14mm

Tooth pitch: 15,875mm

No. of Teeth: 26

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 9.400Ibs

Required pressure: 4.263,76Kg

Shims

Required shims: 4 units

Number of passes: 5

Thickness: 1,422mm

Bushings

Bushing diameter: 75, 80, 85, 90, 95, 100, 105, 110, 115 and 120mm

Bushing length: 152,4mm

Weight: 3,5 Kg. Approx.

Optional Tooling

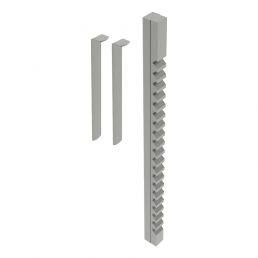

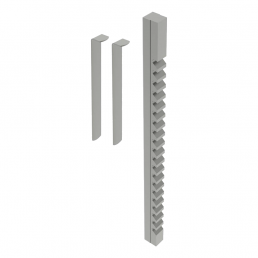

Keyway broaches 20mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00014

Broaching time: 4:20 min.

Tolerance: JS9 (-0,026 +0,015)

Model: F

Broach dimensions: 25,40 x 514,35mm

Standard keys: 20 x 12mm

Tooth pitch: 15,875mm

No. of Teeth: 26

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 8.800Ibs

Required pressure: 3.991,61Kg

Shims

Required shims: 3 units

Number of passes: 4

Thickness: 1,587mm

Bushings

Bushing diameter: 75, 80, 85, 90, 95, 100, 105, 110, 115 and 120mm

Bushing length: 152,4mm

Weight: 3,5 Kg. Approx.

Optional Tooling

Keyway broaches 18mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00013

Broaching time: 3:40 min.

Tolerance: JS9 (-0,022 +0,013)

Model: E

Broach dimensions: 19,05 x 393,7mm

Standard keys: 18 x 11mm

Tooth pitch: 15,875mm

No. of Teeth: 20

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 10.600Ibs

Required pressure: 4.808,07Kg

Shims

Required shims: 3 units

Number of passes: 4

Thickness: 1,422mm

Bushings

Bushing diameter: 52, 54, 55, 56, 58, 60, 62, 63, 64, 65, 66, 68, 70 and 72mm

Bushing length: 127 and 152,4mm

Weight: 1,5 Kg. Approx.

Optional Tooling

Keyway broaches 16mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00012

Broaching time: 3:40 min.

Tolerance: JS9 (-0,024 +0,012)

Model: E

Broach dimensions: 19,05 x 393,7mm

Standard keys: 16 x 10mm

Tooth pitch: 15,875mm

No. of Teeth: 20

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 9.400Ibs

Required pressure: 4.263,76Kg

Shims

Required shims: 3 units

Number of passes: 4

Thickness: 1,422mm

Bushings

Bushing diameter: 52, 54, 55, 56, 58, 60, 62, 63, 64, 65, 66, 68, 70 and 72mm

Bushing length: 127 and 152,4mm

Weight: 1,5 Kg. Approx.

Optional Tooling

Keyway broaches 14mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00011

Broaching time: 2:30 min.

Tolerance: JS9 (-0,023 +0,013)

Model: D

Broach dimensions: 14,28 x 352,42mm

Standard keys: 14 x 9mm

Tooth pitch: 15,875mm

No. of Teeth: 17

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 11.100Ibs

Required pressure: 5.034,87Kg

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 1,587mm

Bushings

Bushing diameter: 32, 34, 35, 36, 38, 40, 42, 44, 45, 46, 48, 50, 52, 54 and 56mm

Bushing length: 101,6 and 127mm

Weight: 1 Kg. Approx.

Optional Tooling

Keyway broaches 12mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00010

Broaching time: 2:30 min.

Tolerance: JS9 (-0,022 +0,014)

Model: D

Broach dimensions: 14,28 x 352,42mm

Standard keys: 12 x 8mm

Tooth pitch: 15,875mm

No. of Teeth: 17

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 8.400Ibs

Required pressure: 3.810,17Kg

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 1,422mm

Bushings

Bushing diameter: 32, 34, 35, 36, 38, 40, 42, 44, 45, 46, 48, 50, 52, 54 and 56mm

Bushing length: 101,6 and 127mm

Weight: 1 Kg. Approx.

Optional Tooling

Keyway broaches 10mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00009

Broaching time: 2:30 min.

Tolerance: JS9 (-0,018 +0,012)

Model: D

Broach dimensions: 14,28 x 352,42mm

Standard keys: 10 x 8mm

Tooth pitch: 15,875mm

No. of Teeth: 17

Minimum cutting length: 25,4mm

Maximum cutting length: 152,4mm

Required pressure: 6.500Ibs

Required pressure: 2.948,35Kg

Shims

Required shims: 2 unidades

Number of passes: 3

Thickness: 1,422mm

Bushings

Bushing diameter: 32, 34, 35, 36, 38, 40, 42, 44, 45, 46, 48, 50, 52, 54 and 56mm

Bushing length: 101,6 and 127mm

Weight: 1 Kg. Approx.

Optional Tooling

Keyway broaches 8mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00008

Broaching time: 2:30 min.

Tolerance: JS9 (-0,017 +0,013)

Model: C

Broach dimensions: 9,52 x 298,45mm

Standard keys: 8 x 7mm

Tooth pitch: 9,525mm

No. of Teeth: 22

Minimum cutting length: 9,921mm

Maximum cutting length: 63,5mm

Required pressure: 3.680Ibs

Required pressure: 1.669,22Kg

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 1,27mm

Bushings

Bushing diameter: 18, 19, 20, 22, 24, 25, 26, 28, 30, 32, 34, 35 and 36mm

Bushing length: 63,5mm

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 6mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00006

Broaching time: 1:20 min.

Tolerance: JS9 (-0,016 +0,009)

Model: C

Broach dimensions: 9,52 x 298,45mm

Standard keys: 6 x 6mm

Tooth pitch: 9,525mm

No. of Teeth: 22

Minimum cutting length: 9,921mm

Maximum cutting length: 63,5mm

Required pressure: 2.100Ibs

Required pressure: 952,54Kg

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 1,587mm

Bushings

Bushing diameter: 18, 19, 20, 22, 24, 25, 26, 28, 30, 32, 34, 35 and 36mm

Bushing length: 63,5mm

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 5mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00005

Broaching time: 1:20 min.

Tolerance: JS9 (-0,014 +0,008)

Model: C

Broach dimensions: 9,52 x 298,45mm

Standard keys: 5 x 5mm

Tooth pitch: 9,525mm

No. of Teeth: 22

Minimum cutting length: 9,921mm

Maximum cutting length: 63,5mm

Required pressure: 1.470Ibs

Required pressure: 666,78Kg

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 1,193mm

Bushings

Bushing diameter: 18, 19, 20, 22, 24, 25, 26, 28, 30, 32, 34, 35 and 36mm

Bushing length: 63,5mm

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 5mm short

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00004

Broaching time: 1:00 min.

Tolerance: JS9 (-0,014 +0,008)

Model: B1

Broach dimensions: 6,35 x 171,45mmm

Standard keys: 5 x 5mm

Tooth pitch: 7,143mm

No. of Teeth: 16

Minimum cutting length: 7,54mm

Maximum cutting length: 42,862mm

Required pressure: 1.860Ibs

Required pressure: 843,68Kg

Shims

Required shims: 1 units

Number of passes: 2

Thickness: 1,27mm

Bushings

Bushing diameter: 12, 14, 15, 16, 17, 18 and 19mm

Bushing length: 42,862mm

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 4mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00003

Broaching time: 1:00 min.

Tolerance: JS9 (-0,015 +0,01)

Model: B1

Broach dimensions: 6,35 x 171,45mm

Standard keys: 4 x 4mm

Tooth pitch: 7,143mm

No. of Teeth: 16

Minimum cutting length: 7,54mm

Maximum cutting length: 42,862mm

Required pressure: 1.140Ibs

Required pressure: 517,09Kg

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,965mm

Bushings

Bushing diameter: 12, 14, 15, 16, 17, 18 and 19mm

Bushing length: 42,862mm

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 3mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00002

Broaching time: 0:45 min.

Tolerance: JS9 (-0,013 +0,009)

Model: A

Broach dimensions: 3,175 x 127mmm

Standard keys: 3 x 3mm

Tooth pitch: 4,762mm

No. of Teeth: 18

Minimum cutting length: 5,159mm

Maximum cutting length: 28,575mm

Required pressure: 650Ibs

Required pressure: 294,83Kg

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,787mm

Bushings

Bushing diameter: 6, 8, 10, 12 and 15mm

Bushing length: 28,575mm

Weight: 0,020 Kg. Approx.

Optional Tooling

Keyway broaches 2mm

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance.

Each set of broach is equipped with its required shims.

REF: 125-09-01-BR-00001

Broaching time: 0:30 min.

Tolerance: JS9 (-0,014 +0,009)

Model: A

Broach dimensions: 3,175 x 127mm

Standard keys: 2 x 2mm

Tooth pitch: 4,762mm

No. of Teeth: 18

Minimum cutting length: 5,159mm

Maximum cutting length: 28,575mm

Required pressure: 720Ibs

Required pressure: 326,58Kg

Shims

Required shims: 0 units

Number of passes: 1

Bushings

Bushing diameter: 6, 8, 10, 12 and 15mm

Bushing length: 28,575mm

Weight: 0,020 Kg. Approx.

Optional Tooling

Keyway broaches 1 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00020

Broaching time: 8:00 min.

Tolerance: JS9 (1,0015 · 1,0025)

Model: F

Broach dimensions: 1 x 20 1/4 inches

Tooth pitch: 5/8 inch

No. of Teeth: 26

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 11.100Ibs

Shims

Required shims: 7 units

Number of passes: 8

Thickness: 0,0625 inches

Bushings

Bushing diameter: 3 1/16, 3 1/8, 3 3/16, 3 1/4, 3 5/16, 3 3/8, 3 7/16, 3 1/2, 3 9/16, 3 5/8, 3 11/16, 3 3/4, 3 13/16, 3 7/8, 3 15/16, 4, 4 1/16, 4 1/8, 4 3/16, 4 1/4, 4 5/16, 4 3/8, 4 7/16, 4 1/2, 7 9/16, 4 5/8, 4 11/16, 4 3/4, 4 13/16, 4 7/8, 4 15/16 and 5 inches

Bushing length: 6 inches

Weight: 3,5 Kg. Approx.

Optional Tooling

Keyway broaches 7/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00019

Broaching time: 6:00 min.

Tolerance: JS9 (0,8765 · 0,8775)

Model: F

Broach dimensions: 1 x 20 1/4 inches

Tooth pitch: 5/8 inch

No. of Teeth: 26

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 9.800Ibs

Shims

Required shims: 6 units

Number of passes: 7

Thickness: 0,0625 inches

Bushings

Bushing diameter: 3 1/16, 3 1/8, 3 3/16, 3 1/4, 3 5/16, 3 3/8, 3 7/16, 3 1/2, 3 9/16, 3 5/8, 3 11/16, 3 3/4, 3 13/16, 3 7/8, 3 15/16, 4, 4 1/16, 4 1/8, 4 3/16, 4 1/4, 4 5/16, 4 3/8, 4 7/16, 4 1/2, 7 9/16, 4 5/8, 4 11/16, 4 3/4, 4 13/16, 4 7/8, 4 15/16 and 5 inches

Bushing length: 6 inches

Weight: 3,5 Kg. Approx.

Optional Tooling

Keyway broaches 3/4 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00018

Broaching time: 5:00 min.

Tolerance: JS9 (0,7515 · 0,7525)

Model: E

Broach dimensions: 3/4 x 15 1/2 inches

Tooth pitch: 5/8 inch

No. of Teeth: 20

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 11.900Ibs

Shims

Required shims: 5 units

Number of passes: 6

Thickness: 0,0625 inches

Bushings

Bushing diameter: 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16, 3, 3 1/16, 3 1/8, 3 3/16, 3 1/4, 3 5/16, 3 3/8, 3 7/16, 3 1/2, 3 9/16, 3 5/8, 3 11/16, 3 3/4, 3 13/16, 3 7/8, 3 15/16 and 4 inches

Bushing length: 6 inches

Weight: 1,5 Kg. Approx.

Optional Tooling

Keyway broaches 5/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00017

Broaching time: 4:00 min.

Tolerance: JS9 (0,6260 · 0,6270)

Model: E

Broach dimensions: 3/4 x 15 1/2 inches

Tooth pitch: 5/8 inch

No. of Teeth: 20

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 9.600Ibs

Shims

Required shims: 4 units

Number of passes: 5

Thickness: 0,0625 inches

Bushings

Bushing diameter: 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16, 3, 3 1/16, 3 1/8, 3 3/16, 3 1/4, 3 5/16, 3 3/8, 3 7/16, 3 1/2, 3 9/16, 3 5/8, 3 11/16, 3 3/4, 3 13/16, 3 7/8, 3 15/16 and 4 inches

Bushing length: 6 inches

Weight: 1,5 Kg. Approx.

Optional Tooling

Keyway broaches 9/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00016

Broaching time: 3:40 min.

Tolerance: JS9 (0,5631 · 0,5641)

Model: D

Broach dimensions: 9/16 x 13 7/8 inches

Tooth pitch: 5/8 inch

No. of Teeth: 17

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 8.900Ibs

Shims

Required shims: 4 units

Number of passes: 5

Thickness: 0,0560 inches

Bushings

Bushing diameter: 1 7/16, 1 1/2, 1 9/16, 1 5/8, 1 11/16, 1 3/4, 1 13/16, 1 7/8, 1 15/16, 2, 2 1/16, 2 1/8, 2 3/16, 2 1/4, 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16 and 3 inches

Bushing length: 4, 5 and 6 inches

Weight: 1,00 Kg. Approx.

Optional Tooling

Keyway broaches 1/2 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00015

Broaching time: 3:00 min.

Tolerance: JS9 (0,5006 · 0,5016)

Model: D

Broach dimensions: 9/16 x 13 7/8 inches

Tooth pitch: 5/8 inches

No. of Teeth: 17

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 9.800Ibs

Shims

Required shims: 3 units

Number of passes: 4

Thickness: 0,0625 inches

Bushings

Bushing diameter: 1 7/16, 1 1/2, 1 9/16, 1 5/8, 1 11/16, 1 3/4, 1 13/16, 1 7/8, 1 15/16, 2, 2 1/16, 2 1/8, 2 3/16, 2 1/4, 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16 and 3 inches

Bushing length: 4, 5 and 6 inches

Weight: 1,00 Kg. Approx.

Optional Tooling

Keyway broaches 7/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00014

Broaching time: 3:00 min.

Tolerance: JS9 (0,4380 · 0,4390)

Model: D

Broach dimensions: 9/16 x 13 7/8 inches

Tooth pitch: 5/8 inch

No. of Teeth: 17

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 9.400Ibs

Shims

Required shims: 3 units

Number of passes: 4

Thickness: 0,0560 inches

Bushings

Bushing diameter: 1 7/16, 1 1/2, 1 9/16, 1 5/8, 1 11/16, 1 3/4, 1 13/16, 1 7/8, 1 15/16, 2, 2 1/16, 2 1/8, 2 3/16, 2 1/4, 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16 and 3 inches

Bushing length: 4, 5 and 6 inches

Weight: 1,00 Kg. Approx.

Optional Tooling

Keyway broaches 3/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00013

Broaching time: 2:30 min.

Tolerance: JS9 (0,3755 · 0,3765)

Model: D

Broach dimensions: 9/16 x 13 7/8 inches

Tooth pitch: 5/8 inch

No. of Teeth: 17

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 7.000Ibs

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 0,0625 inches

Bushings

Bushing diameter: 1 7/16, 1 1/2, 1 9/16, 1 5/8, 1 11/16, 1 3/4, 1 13/16, 1 7/8, 1 15/16, 2, 2 1/16, 2 1/8, 2 3/16, 2 1/4, 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16 and 3 inches

Bushing length: 4, 5 and 6 inches

Weight: 1,00 Kg. Approx.

Optional Tooling

Keyway broaches 5/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00012

Broaching time: 2:30 min.

Tolerance: JS9 (0,3127 · 0,3137)

Model: D

Broach dimensions: 9/16 x 13 7/8 inches

Tooth pitch: 5/8 inch

No. of Teeth: 17

Minimum cutting length: 1 inch

Maximum cutting length: 6 inches

Required pressure: 8.000Ibs

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 0,0560 inches

Bushings

Bushing diameter: 1 7/16, 1 1/2, 1 9/16, 1 5/8, 1 11/16, 1 3/4, 1 13/16, 1 7/8, 1 15/16, 2, 2 1/16, 2 1/8, 2 3/16, 2 1/4, 2 5/16, 2 3/8, 2 7/16, 2 1/2, 2 9/16, 2 5/8, 2 11/16, 2 3/4, 2 13/16, 2 7/8, 2 15/16 and 3 inches

Bushing length: 4, 5 and 6 inches

Weight: 1,00 Kg. Approx.

Optional Tooling

Keyway broaches 3/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00011

Broaching time: 2:30 min.

Tolerance: JS9 (0,3755 · 0,3765)

Model: C

Broach dimensions: 3/8 x 11 3/4 inches

Tooth pitch: 3/8 inch

No. of Teeth: 22

Minimum cutting length: 25/64 inch

Maximum cutting length: 2 1/2 inches

Required pressure: 4.340Ibs

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 0,0625 inches

Bushings

Bushing diameter: 3/4, 13/16, 7/8, 15/16, 1, 1 1/16, 1 1/8, 1 3/16, 1 1/4, 1 5/16, 1 3/8, 1 7/16, 1 1/2 and 1 9/16 inches

Bushing length: 2 1/2 inches

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 5/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00010

Broaching time: 2:30 min.

Tolerance: JS9 (0,3127 · 0,3137)

Model: C

Broach dimensions: 3/8 x 11 3/4 inches

Tooth pitch: 3/8 inch

No. of Teeth: 22

Minimum cutting length: 25/64 inch

Maximum cutting length: 2 1/2 inches

Required pressure: 3.960Ibs

Shims

Required shims: 2 units

Number of passes: 3

Thickness: 0,0550 inches

Bushings

Bushing diameter: 3/4, 13/16, 7/8, 15/16, 1, 1 1/16, 1 1/8, 1 3/16, 1 1/4, 1 5/16, 1 3/8, 1 7/16, 1 1/2 and 1 9/16 inches

Bushing length: 2 1/2 inches

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 1/4 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00009

Broaching time: 1:20 min.

Tolerance: JS9 (0,2502 · 0,2512)

Model: C

Broach dimensions: 3/8 x 11 3/4 inches

Tooth pitch: 3/8 inch

No. of Teeth: 22

Minimum cutting length: 25/64 inch

Maximum cutting length: 2 1/2 inches

Required pressure: 2.520Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0625 inches

Bushings

Bushing diameter: 3/4, 13/16, 7/8, 15/16, 1, 1 1/16, 1 1/8, 1 3/16, 1 1/4, 1 5/16, 1 3/8, 1 7/16, 1 1/2 and 1 9/16 inches

Bushing length: 2 1/2 inches

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 3/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00008

Broaching time: 1:20 min.

Tolerance: JS9 (0,1877 · 0,1887)

Model: C

Broach dimensions: 3/8 x 11 3/4 inches

Tooth pitch: 3/8 inch

No. of Teeth: 22

Minimum cutting length: 25/64 inch

Maximum cutting length: 2 1/2 inches

Required pressure: 1.540Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0500 inches

Bushings

Bushing diameter: 3/4, 13/16, 7/8, 15/16, 1, 1 1/16, 1 1/8, 1 3/16, 1 1/4, 1 5/16, 1 3/8, 1 7/16, 1 1/2 and 1 9/16 inches

Bushing length: 2 1/2 inches

Weight: 0,350 Kg. Approx.

Optional Tooling

Keyway broaches 3/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00007

Broaching time: 1:00 min.

Tolerance: JS9 (0,1877 · 0,1887)

Model: B

Broach dimensions: 3/16 x 6 3/4 inches

Tooth pitch: 9/32 inch

No. of Teeth: 16

Minimum cutting length: 19/64 inch

Maximum cutting length: 1 11/16 inches

Required pressure: 1.860Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0500 inches

Bushings

Bushing diameter: 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7/8 inch

Bushing length: 1 11/16 inches

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 5/32 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00006

Broaching time: 1:00 min.

Tolerance: JS9 (0,1564 · 0,1574)

Model: B

Broach dimensions: 3/16 x 6 3/4 inches

Tooth pitch: 9/32 inch

No. of Teeth: 16

Minimum cutting length: 19/64 inch

Maximum cutting length: 1 11/16 inches

Required pressure: 1.320Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0420 inches

Bushings

Bushing diameter: 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7/8 inch

Bushing length: 1 11/16 inch

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 1/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00005

Broaching time: 1:00 min.

Tolerance: JS9 (0,1252 · 0,1262)

Model: B

Broach dimensions: 3/16 x 6 3/4 inches

Tooth pitch: 9/32 inch

No. of Teeth: 16

Minimum cutting length: 19/64 inch

Maximum cutting length: 1 11/16 inch

Required pressure: 720Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0310 inches

Bushings

Bushing diameter: 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7/8 inch

Bushing length: 1 11/16 inch

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 3/32 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00004

Broaching time: 0:40 min.

Tolerance: JS9 (0,0938 · 0,0948)

Model: B

Broach dimensions: 3/16 x 6 3/4 inches

Tooth pitch: 9/32 inch

No. of Teeth: 16

Minimum cutting length: 19/64 inch

Maximum cutting length: 1 11/16 inch

Required pressure: 930Ibs

Shims

Required shims: 0 units

Number of passes: 1

Bushings

Bushing diameter: 1/2, 9/16, 5/8, 11/16, 3/4, 13/16 and 7/8 inch

Bushing length: 1 11/16 inch

Weight: 0,100 Kg. Approx.

Optional Tooling

Keyway broaches 1/8 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00003

Broaching time: 0:45 min.

Tolerance: JS9 (0,1252 · 0,1262)

Model: A

Broach dimensions: 1/8 x 5 inches

Tooth pitch: 3/16 inchs

No. of Teeth: 18

Minimum cutting length: 13/64 incha

Maximum cutting length: 1 1/8 inch

Required pressure: 650Ibs

Shims

Required shims: 1 unit

Number of passes: 2

Thickness: 0,0310 inches

Bushings

Bushing diameter: 1/4, 5/16, 3/8, 7/16 and 1/2 inch

Bushing length: 1 1/8 inch

Weight: 0,020 Kg. Approx.

Optional Tooling

Keyway broaches 3/32 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00002

Broaching time: 0:30 min.

Tolerance: JS9 (0,0938 · 0,0948)

Model: A

Broach dimensions: 1/8 x 5 inches

Tooth pitch: 3/16 inches

No. of Teeth: 18

Minimum cutting length: 13/64 inch

Maximum cutting length: 1 1/8 inches

Required pressure: 780Ibs

Shims

Required shims: 0 units

Number of passes: 1

Bushings

Bushing diameter: 1/4, 5/16, 3/8, 7/16 and 1/2 inch

Bushing length: 1 1/8 inches

Weight: 0,020 Kg. Approx.

Optional Tooling

Keyway broaches 1/16 inch

Broaches made of treated and rectified steel of first level to optimize the perfect finish of the piece and the exact tolerance. Each set of broach is equipped with its required shims.

REF: 125-09-01-BRP-00001

Broaching time: 0:30 min.

Tolerance: JS9 (0,0625 · 0,0635)

Model: A

Broach dimensions: 1/8 x 5 inches

Tooth pitch: 3/16 inches

No. of Teeth: 18

Minimum cutting length: 13/64 inch

Maximum cutting length: 1 1/8 inches

Required pressure: 390Ibs

Shims

Required shims: 0 units

Number of passes: 1

Bushings

Bushing diameter: 1/4, 5/16, 3/8, 7/16 and 1/2 inch

Bushing length: 1 1/8 inches

Weight: 0,020 Kg. Approx.

Optional Tooling

+ Info for Vertical Broaching Machines BM25

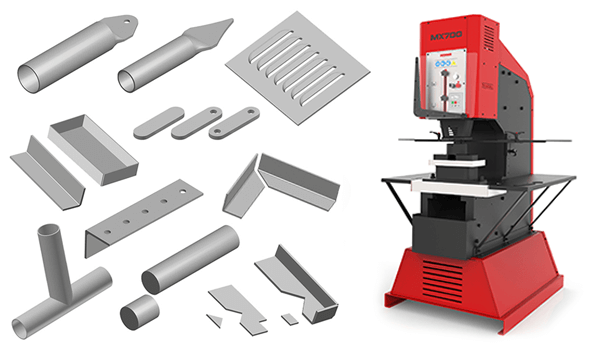

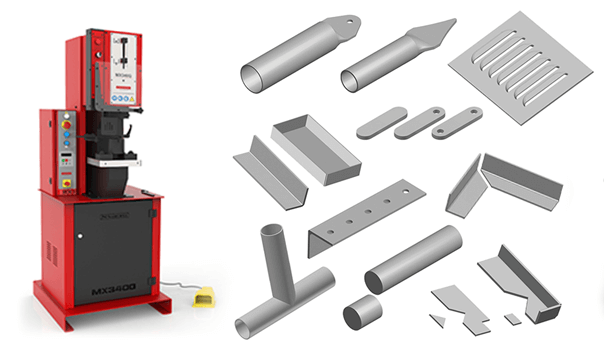

The Internal keyway broaching machine BM25 is not only capable of making slots for keyways (notches), but also polygonal shapes from cylindrical holes (squares, rectangles, hexagons,...)

It is also possible to make a given number of slots from the same hole and even getting to generate inner grooves.

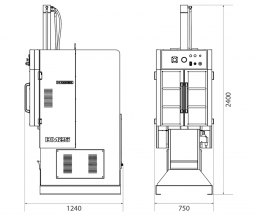

Dimensions of the machine Vertical Broaching Machines BM25

Characteristics of the packaging Vertical Broaching Machines BM25

Uses of the machine Vertical Broaching Machines BM25

The Hydraulic Broaching machine BM25 NARGESA is an equipment to make notches and slots or keyways in all kinds of pieces: Sprockets, pulleys, gears... it is thought for small and medium productions, it is characterized by its great versatility, reliability, easy handling and fast setting up.