The Hydraulic Press PI85 Nargesa, is a NOVELTY in the world of locks.

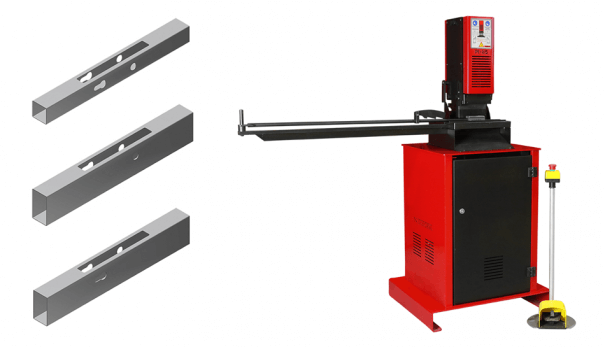

Hydraulic press for locks PI85 Nargesa, with a fast and accurate perforation for the casing , handle and lock hole in a pipe. It's a state-of-the-art NOVELTY in the world of locks. Patented by Nargesa from 2006 makes us the leaders in the manufacturing of this kind of machine. They fit 85% of locks of all trademarks and models.

All products Nargesa are according to the European CE normative and regulations for the manufacturing of industrial machinery.

Technical features

The Hydraulic Press PI85 NARGESA, is a NOVELTY in the world of locks. It was patented by Nargesa in 2006 which makes us leaders in the manufacturing of this kinds of machines. They fit 85% of locks of all trademarks and models.

- Normally, one operative has an average time between 30 - 45 minutes to make one whole operation for a casing, handle holes and the lock hole in a square or rectangular pipe. With the PI85 Nargesa the time gets reduced to less than one minute. This is a machine for high production.

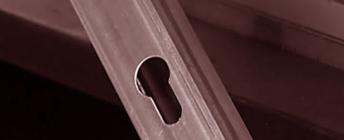

- The finish is perfect, with the proper tolerance to place the lock with no need to use a bezel. Thus the assembling time is minimum.

- Many companies that have bought this press for locks PI85, not only for their own use but also to sell the ready-to-be-used pipes to other companies.

- The pipes that can be used with the machine are 35x35, 40x40, 40x50, 40x60, 40x70, 40x80, 50x50, 50x60, 50x70 and 50x80.

- Pipe thickness can be 1,5 mm and 2 mm. No matter the material, it can either punch normal steel, galvanized steel or stainless steel.

- It's important to bear in mind the casing must be always made in the side of 35, 40 or 50 mm.

- The perforation of the lock hole and the handle could be combined, it means we can punch a pipe with lock and handle on both ends, as we can as well make either the handle or the lock in the other.

- The casing length is adjustable as it is as well the entrance of the lock. It ranges from 18 mm to 37 mm.

Characteristics of the machine

- Hydraulic punching system.

- Safety pedal.

- Operation time 58 secodns (approximately).

- Type of keyhole: Bombin.

- Type of material: M.S., S.S., Galvanized steel...

- Pipe Thickness: 1,5 mm and 2 mm.

- Adjustable casing length.

- Adjustable lock entrance from 18 mm to 37 mm.

- PI 85 distance between axis 85 mm.

- Motor power: 0,75 KW / 1HP.

- 3-phased tension: 230/400V.

Examples, Trade marks, Locks

Tesa: Ref 2010B, 2211, 2240, 2241, 2230, 2231, 2236, 2237

Serraller: Ref 20020, 20023, 20025, 20028, 20030, 20035

Lince: Ref 5530, 5532, 5542, 5570, 5571, 5572, 5590, 5402, 5403

MCM: Ref 1650, 1449, 1450, 2449, 2450, 2419, 2350

For different sizes please ask the manufacturers.

For single phased machines ask quotation.

Lower bench palletized to move the machine easily to the working site or storage.

The machine is delivered completely assembled.

Packing with a steel pallet and a 3-layered cardborad box suitable for sea freight.

Optional: Complete wooden packing NIMF15.

All our products are manufactured in our facilities in Spain. Hydraulic and electronic components are completely standard from the best European leading trademark with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Optional accesories for Hydraulic Press for Locks PI85

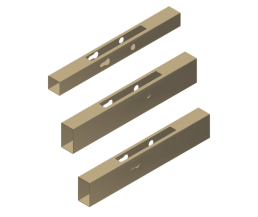

Tooling for 35x35 pipe. wall thickness 1,5mm

REF: 140-07-01-00001

PIPE: 35x35mm

THICKNESS: 1,5mm

PIECES PER DIE: 3 Units.

WEIGHT: 5 kg.

Tooling for 40x40mm pipe up to 40x80mm. wall thickness: 1,5mm

REF: 140-07-01-00003

PIPE: 40x40mm, 40x50mm, 40x60mm, 40x70mm, 40x80mm.

THICKNESS: 1,5mm

PIECES PER DIE: 8 Units.

Tooling for 40x40mm pipe up to 40x80mm. wall thickness: 2mm

PIPE: 40x40mm, 40x50mm, 40x60mm, 40x70mm, 40x80mm.

THICKNESS: 2mm

PIECES PER DIE: 8 Units.

WEIGHT: 5,3 kg.

Tooling for 50x50mm pipe up to 50x80mm. wall thickness: 1,5mm.

PIPE: 50x50mm, 50x60mm, 50x70mm, 50x80mm.

THICKNESS: 1,5mm

PIECE PER DIE: 7 Units.

WEIGHT: 5,5 kg.

+ Info for Hydraulic Press for Locks PI85

The Hydraulic Press for Locks Nargesa allows making different kinds of punching operations:

- Punching for mechanism entrance, the lock and handle to both sides.

- Punching for mechanism entrance, the lock and handle in only one side.

- Punching for mechanism entrance, the lock with no handle.

The types of punching are applicable to all the pipes the machine can work with: 35x35 / 40x40 / 40x50 / 40x60 / 40x70 / 40x80 / 50x50 / 50x60 / 50x70 / 50x80

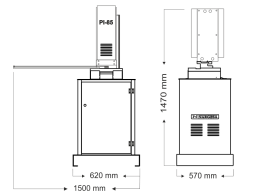

Dimensions of the machine Hydraulic Press for Locks PI85

Characteristics of the packaging Hydraulic Press for Locks PI85

Nº Pallets: 1.

Width: 660 mm.

Length: 580 mm.

Height: 1640 mm.

Volume: 0,65 m3

Nett Weight: 200 Kg.

Gross Weight: 212 Kg.

Tariff Item Code: 84624900

Other features:

- Palletized base to move it easily to the working site or storage.

- The machine is delivered completely mounted.

- Packing in a steel pallet and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packing NIMF15.

Uses of the machine Hydraulic Press for Locks PI85

Hydraulic Press for locks PI85 es thought to make a fast and precise punching for lock casings in a pipe. In just 58 seconds you will obtain the whole operation: the lock casing, the keyhole and the handle. Its design makes it a machine easy to move to the working site. It is suitable for 85% of locks in the market. It's a very easy to use machine.