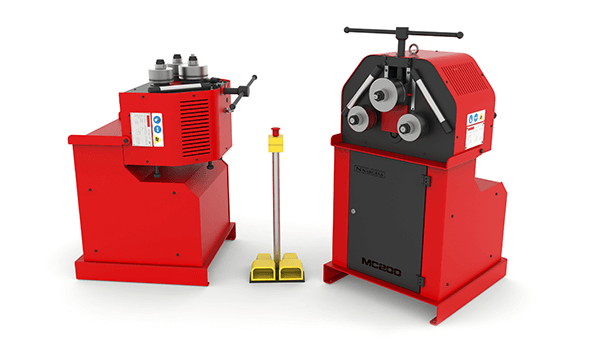

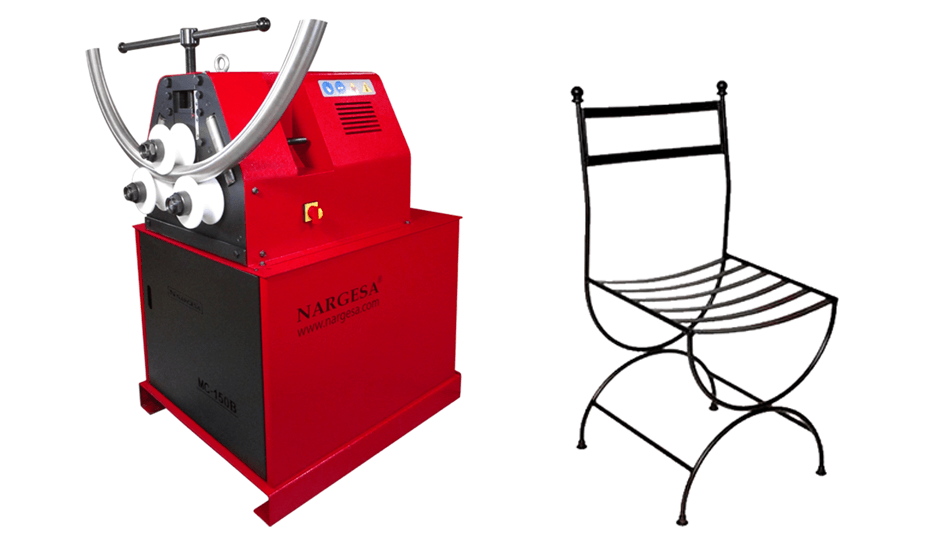

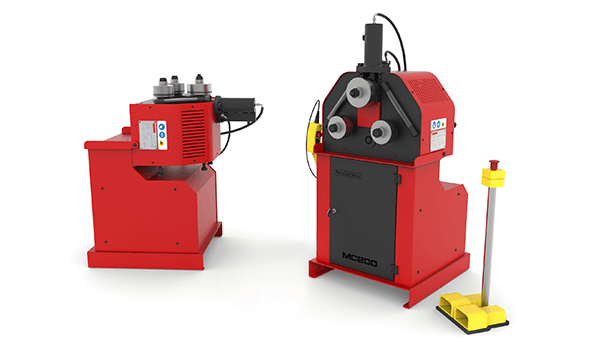

Ring roller bender and section bending machine MC200 NARGESA fabricated in steel, two traction rollers, pinion transmissions, treated and rectified. Maximum capacity for bending round pipe: 2” 1/2 inches or 63,5 mm.

Profile Former MC200 NARGESA, made of welded and mechanized steel sheet. Unlike the others, this one is not made of cast iron. Ideal for making flanges, greenhouses, balausters, tables, chairs, doors, windows... making a great number of circular shape in all kinds of profiles. Its robustness, axis diameter, reducer capacity and other features, make it one of the best bending machines in the market, within the category of two traction rollers. All products Nargesa are according to the European directives and regulations CE regarding manufacturing of industrial machinery.

Our customers say

Technical features

- It's got two traction rollers. The two lower rollers are knurled and motorized to achieve a better traction.

- Safe transmision by treated and flat pinions.

- Steel treated and rectified axis.

- Diameter of axes: 40 mm.

- Useful axes length: 74 mm.

- Center distance between lower axes: 286 mm.

- Maximum capacity for bending round pipe: 2 1/2 inch or 63.5 mm.

- Max. bending capacity in round pipes: 2" 1/2 inch or 63.5 mm.

- Bending regulation by means of the upper axis which permits to make bending operations in big pipes and profiles diameters without any distortion.

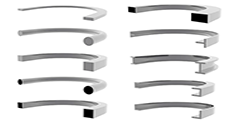

- It's equipped with 9 standard rollers and washers by means of which you can make all kinds of profiles. (Square pipe, rectan-gular, solid square bar, round and rectangular, U profile, T profile, angle, flat bar, edge flat bar,…).

- Millimeter scale in the upper axis to regulate bending.

- Vertical and Horizontal working position in the same table.

- Side corrector rollers to rule the bending operation and make spiral bendings.

- Motor Power: 1,1 KW / 1,5 HP.

- Voltage supply: 3 phased 230/400 V.

- For single phased machines, request quotation.

- Rollers speed: 8 RPM.

- Lower bench palletized to easily transport the machine to the workplace or store it in case of lacking space.

- The machine is shipped fully assembled, you only need to connect it to the power supply.

- Palet made of steel and 3 layer cardboard box suitable for seafreight.

- Optional: Fumigated wooden box ISPM15.

All our products are manufactured in our facilities in Spain. The hydraulic and electronic components are completely standard and from leading European brands, with service worldwide: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

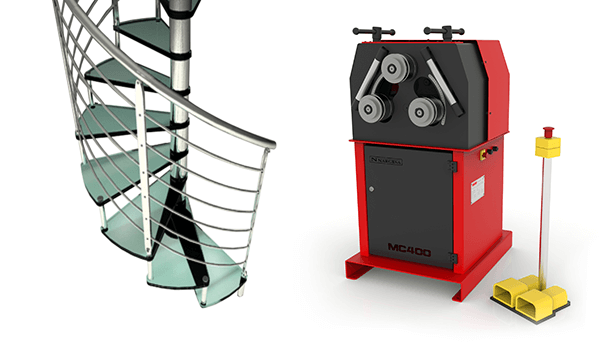

Nargesa section bending machines capacity

In the PDF file you will see and download the bending capacity for Profile Formers. This are guidance sizes, it always depends a lot on the material hardness and quality of the pipe of profile.

Download (170.72 KB)

Optional accesories for Ring roller bender section machine MC200

Treated steel rollers

Rollers made of Steel F155 and treated to 62 Rc. Suitable for bending all kind of round steel or stainless steel pipes.

Always clean up the rollers well before using stainless steel not to get the pipe contaminated.

Download (685.73 KB)

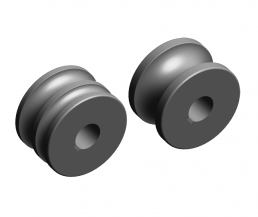

Sustarin rollers

Rollers made of Sustarin to bend round stainless steel pipes, aluminium and delicate materials with thickness not bigger than 2.5mm.

Sustarin rollers do not danage nor get the pipe contaminated.

Download (740.47 KB)

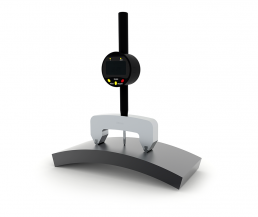

High precision digital radius gauge

Especially designed for measuring radii on profiles.

REF: 140-MED08-00001

The High precision digital radius gauge allows the user to have a direct and immediate reading of inner and outer radius in a range from 55 to 11.250 millimeters or from 2" to 443" inches.

The High precision digital radius gauge measures radii in spherical objects such as tubes, profiles and pipes in a quick and accurate way.

It is really fast and easy to use! It indicates the inner or outer radius of the part we are bending without removing it from the machine and without needing to previously draw and cut a guide template.

- Includes 3V CR2032 lithium battery

- Includes 3 measurement arcs (100, 200 and 300 mm).

- Supplied with a shock-resistant stainless Steel briefcase.

Included accesories for Ring roller bender section machine MC200

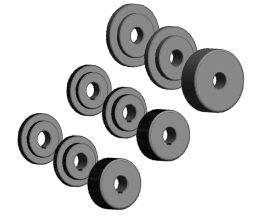

Standard rollers MC150B/MC200/MC200H

It's equipped with 9 standard pieces, by means of which the user can work all kinds of profiles. Square., rectangular pipe, solid round and square bars. U Profile, T profile, angle, flat bar, edged flat bar...

Adjustable rollers. The user may combine the setup position and it will allow bending the differentprofiles, adapting the sizes.

Steel rollers F1140 treated and rectified.

Download (983.52 KB)

+ Info for Ring roller bender section machine MC200

2 BENDING SHAPES: VERTICAL AND HORIZONTAL.

When the user has to bend any kind of profile at radius wider than 2 m or if there are height problems in the facilities, it is really uncomfortable to work vertically. We just have to tilt the work bench of the section bending machine so the bending operation is made horizontally with the help of a support or stands where we place the piece in order to obtain an optimous job. Fo isntance, when we bend archs for a grrenhouse.

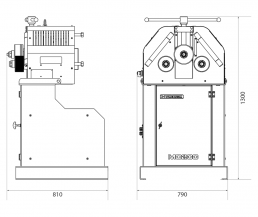

Dimensions of the machine Ring roller bender section machine MC200

Characteristics of the packaging Ring roller bender section machine MC200

Nº Pallets 1.

Width: 700 mm 27,6"

Length: 830 mm 32,7"

Height: 1380 mm 54,3"

Volume: 0,80 m3

Nett Weight: 320 Kg 705,5lb

Gross Weight: 335 Kg 738,6lb

Tariff Item Code: 84622900

Other Features:

- Palletized bench to transport it easily to the working site or storage.

- The machine is sent completely mounted.

- Packeaging with steel pallet and 3-layered cardboard box, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine Ring roller bender section machine MC200

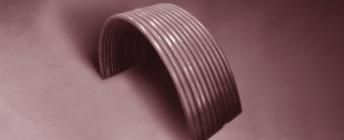

Profile Former MC200 NARGESA, manufactured in mechanized and welded steel unlike others it's not made of wrought iron. It can bend any kind of profiles: Round, square and rectangular pipes, U profiles, T profiles, angles, flat bar, edge flat bar.... Ideal for manufacturing flanges, greenhouses, handrails, tables, chairs, doors, windows... making a great number of circular shapes in all kinds of profiles. Ideal for manufacturing of heat exchangers in copper, aluminum, brass, bronze, iron, steel... especially for bending coil heat exchangers.