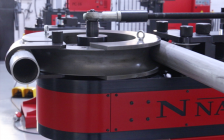

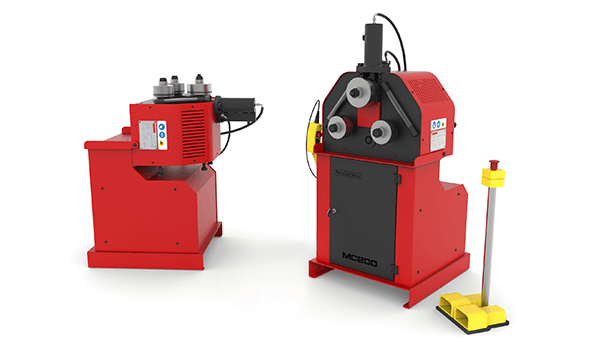

NEW generation of CC90 Non-mandrel tube and pipe bender. Maximum working stroke: 88.9 mm or 3” Schedule 40 or 3” 1/2 Whitworth or 3” ISO x 6 mm 0.2".

The new generation of CC90 Non-mandrel rotary tube and pipe bender can bend up to 180º curves on hollow profiles ensuring the best bent finishes in today’s market. Equipped with a Touch Screen control grant the user interactaction with the standard features offered using the latest 4.0 technology. The sleek look, versatility and faster bending speeds also allows us to have one of best machines offered in our industry. Materials can be round, oval, square, rectangular and made of different metals such as steel, aluminum, stainless steel, copper...

All Nargesa’s Products are according to CE regulations for the manufacturing of industrial machinery.

Our customers say

Technical features

The mandrel-less tube and pipe bending machines Nargesa are perfect for making curves with a constant quality for pipes, tubes, square bars, rods and other profiles.

- Maximum size on S275 round steel pipe: 90mm or 3” Schedule or 3” 1/2 Whitworth or 3” ISO x 6mm.

- Maximum size on aluminum pipe: 88,9mm x 10 mm / 3"1/2 x .393"

- Maximum size on stainless steel pipe 304 /316: 88,9mm x 4mm / 3"1/2 x .157"

- Maximum size on square tube: 60x60x4mm / 2.362" x 2.362" x .157"

- Maximum angle of curvature: 180º

- Automatic rotation speed from 0,75 up 2,2 rpm

- Minimum radius of curvature: 3 times the pipe diameter.

- Maximum radius of curvature: 390 mm or 15,35”

- Repetition on the curve of +/- 0.1 degrees

- Reinforcement tool post support arm for pipes with diameters over 40 mm included.

- 400 ml BEND 8 lubricant included.

- Two bending directions, right or left for easier bending.

- Quick die change over: Maximum 60 seconds.

- 4.0 Technology

- CNC control with 7” touchscreen with more than 20 different languages

- Safety pedal to the right and left.

- Side shelving to store tools.

- All bend dies are made of tempered steel for longer tool life.

- The counter dies are made of bronze alloys to help prevent markings on the outside of the bent profiles.

- Stores up to 10,000 programs.

- Up to 50 different angles on the same piece can be programmed.

- Dimensions can be programmed in inches or millimeters.

- Pivot system with automatic unlocking to help remove material.

- Automatic and programmable spring back correction.

- Automatic unlocking

- Automatic and programmable springback

- Offset head for complex parts.

- Reinforcement tool post support included

- Packaging included

- Motor power: 2,2 KW / 3 HP.

- Electrical voltage: 230/400V Three-phased 50/60Hz

- Intensity: 9/5 A

- Machine weight: 860Kg

- A lower pallet bench to transport the machine to the worksite or storage.

- The CC90 pipe bender is sent completely assembled.

- 3-layer cardboard box suitable for seafreight.

- Optional: NIMF15 wooden container.

All our products are manufactured in our facilities in Spain. Hydraulic and electrical components are all standard from the best leading European trademarks with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato...

What you should know before purchasing a pipe bender

4.0 Technology: Whenever a customer agrees, the manufacturer may remotely connect to their machine to do any software updates completely free of cost and detect any anomalies in the machine without needing to travel to the machine site.

Robustness and speed: The weight of the machine in comparison to other brands provides an idea of how it’s built. Some models can double the others in weight. These are not DIY machines; they’re pipe benders that can work 24 hours a day.

Curve thicknesses and finishes: The original counter-shape designed by Nargesa guarantee a good finish even with a thin-walled pipe.

Offset head and two-directional bending: The offset head design allows for complex curves as the pipe goes below it.

Enhanced energy efficiency: The consumption per machine working stroke has been significantly reduced to save energy.

Automatic unlock: The bending carriage moves automatically to the right or to the left depending on the direction of the curve to more easily release the piece without needing to re-adjust the grip.

Reinforcement strap included: The CNC pipe bender comes standard with a reinforcement arm. It’s used to prevent machine chassis deformations.

Bend 8 Lubricant included: With the purchase of the CC60 CNC pipe bender, you’ll receive a 400 ml bottle of special bending lubricant.

Download (448.81 KB)

Optional accesories for Non-mandrel tube and pipe bender CC90 CNC

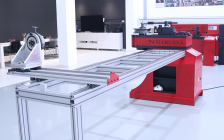

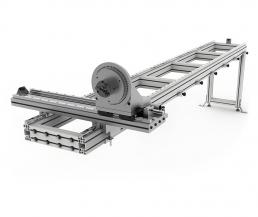

Cc90 2-axis positioning gauge

The gauge of the CC90 allows to make mass produced parts, much faster, more accurate and repetitively.

- Adjustable longitudinal positioning with 6 positions

- Angular head rotation every 5 degrees

- Four-clamp plate adjustable to round and square tube

- Longitudinal movement with high precision linear guides

- Automatic anti-collision control

- Easy handling and preparation for difficult parts

REF: 140-17-02-50000

Gauge length: 3000 mm

Maximum capacity: 90 mm, 3” Schedule

Weight: 137 Kg

CHARACTERISTICS OF THE PACKAGING

Nº Pallets: 1.

Width: 3130 mm.

Length: 1250 mm.

Height: 720 mm.

Volume: 2,82 m3

Nett weight: 137 Kg.

Gross Weight: 187 Kg.

Otras características:

- The stopper of the CC90 pipe bender is shipped fully assembled, it will only be necessary to place the legs and fix it to the ground.

- Wooden pallet and 3-layer wooden and cardboard box suitable for sea transport.

- Optional: Complete wooden packaging NIMF15.

VIDEO - Positioning gauge instructions book

Download (12.27 MB)

Nargesa Bend8 aerosol lubricant

BEND8 lubricant is a high-additive and low-viscosity aerosol oil. Contains PTFE. Does not contain silicone.

- Enables the finish on the outer bend

- Inhibits roughness and inner marks

- Reduces wear of the tooling

- Especially designed for tubes of small thickness

- Lubricates to reduce friction

- Avoids and disolves corrosion

- Gives shine and protects

- Cleans up and removes dirt

Formats available for this product:

REF. 060-SPR-00003 400 ml bottle.

REF. 060-SPR-00004 Box of 12 400 ml bottles.

Tariff Item Code: 27101999

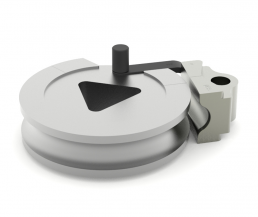

Accessories for round pipes in millimeters · 12 to 90 mm

Rollers made of treated Steel. Units suitable for bending all types of round pipes 12 to 90 millimeters.

The following is supplied with the unit: A main roller, a counter-shape, a clamp with a fastener.

Customers must equip their pipe bender with a specific die to get the desired curving.

The diameter and thickness of the pipe as well as the radius of curvature must be taken into account when choosing a roller.

Check with the manufacturer for other dimensions

Download (439.05 KB)

Accessories for round pipes in Schedule inches · 3/8” to 3” Schedule

Rollers made of treated Steel. Units suitable for bending all types of round pipes 3/8” to 3” Schedule.

The following is supplied with the unit: A main roller, a counter-shape, a clamp with a fastener.

Customers must equip their pipe bender with a specific die to get the desired curving.

The diameter and thickness of the pipe as well as the radius of curvature must be taken into account when choosing a roller.

Check with the manufacturer for other dimensions

Download (867.77 KB)

Accessories for round tubes in inches · 1/2” to 3” 1/2 inches

Rollers made of treated Steel. Units suitable for bending all types of round pipes 1/2” to 3” 1/2 inches.

The following is supplied with the unit: A main roller, a counter-shape, a clamp with a fastener.

Customers must equip their pipe bender with a specific die to get the desired curving.

The diameter and thickness of the pipe as well as the radius of curvature must be taken into account when choosing a roller.

Check with the manufacturer for other dimensions

Download (493.02 KB)

Accessories for square pipes CC90

Rollers made of treated Steel. Units suitable for bending all types of square pipes 20 to 50 millimeters and 3/4” to 2” inches.

The following is supplied with the unit: A main roller, a counter-shape, a clamp with a fastener.

Customers must equip their pipe bender with a specific die to get the desired curving.

The dimensions and thickness of the pipe as well as the radius of curvature must be taken into account when choosing a roller.

Check with the manufacturer for other dimensions

Download (367.53 KB)

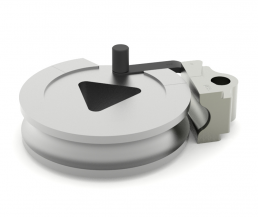

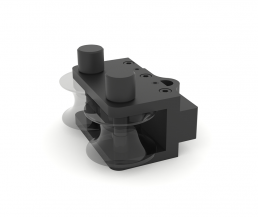

Supporting roller kit CC90

REF: 140-17-02-00002

The CC90 Supporting Roller Kit is used to bend pipes with a diameter equal to or more than 3" Schedule x 3,05mm or 3" 1/2 x 4mm. This unit is comprised of:

A roller holder: The roller holder is made up of three highly resistant steel pieces that are precision mechanized and treated on the surface. They’re fixed and centered with rectified bolts to ensure proper operation.

The coupling axis: The coupling axis is made up of a chrome Ø20 mm Matera axis

Weight: 24,573 kg

+ Info for Non-mandrel tube and pipe bender CC90 CNC

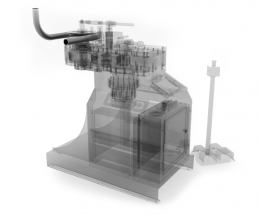

ESA S820 CONTROL PANEL

Nargesa tube and pipes benders are controlled with a very intuitive and easy-to-use 7” color touchscreen with the latest 4.0 technology. Just enter the pipe dimensions, thickness, angle of the curve or curves and choose a die from the library and the control programs the rest of the parameters automatically; elastic recovery correction (springback), recommended rotation speed, whether a tool post support is necessary or not, and if the intended curve is possible... All of this may be modified by the end user based on their own needs. These are some of the most relevant features of this control system.

- Stores up to 10,000 programs.

- Up to 50 different angles on the same piece can be programmed.

- Dimensions may be programmed in inches or millimetres.

- A library of available dies with the possibility of programming new ones.

- A library of differently shaped pipes with varying thicknesses.

- The CNC can be supplied in more than 20 different languages.

- Automatic or manual rotation speed adjustment from 0.7 to 4.5 rpm.

- Manual or automatic operation.

- Automatic elastic recovery correction (springback).

- Piece counter.

- Independent correction of the programmable final curve degree.

- 4.0 Technology.

- On-screen alarm diagnostics.

- Preventive maintenance warning.

- Can be remotely connected by the manufacturer without having to travel to the machine site.

- Warning on screen if the tool post support needs to be used.

- 7” LCD colour touch-screen with 800 x 480 resolution.

- Silicon disk 512MB – Micro SD 4GB for retained data

- 3 analogue inputs, 0-10V - 12 bit resolution.

- 2 analogue outputs, 0-10V - 12 bit resolution.

- 16 digital inputs (24 Vdc).

- 16 digital outputs (24 Vcc, 1,2 A max.) Protected against overloads and short circuits.

- 1 RS232 serial port.

- 1 CAN port with 9 D-Sub F connector contacts.

- 24 Vdc power source.

- 1 USB port.

- Operating temperature: +5 to +50 °C

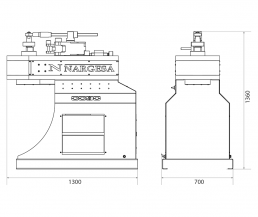

Dimensions of the machine Non-mandrel tube and pipe bender CC90 CNC

Characteristics of the packaging Non-mandrel tube and pipe bender CC90 CNC

Nº Pallets: 1.

Width: 800mm 31,5"

Length: 1440mm 56,7"

Height: 1540mm 60,6"

Volume: 1,77m3

Nett weight: 860 Kg 1896lb

Gross Weight: 920Kg 2028,3lb

Tariff Item Code: 84622600

Otras características:

- Palletized bench to move the machine easily to the working site or storage.

- The machine is delivered completely mounted.

- Packaging with wooden pallet and 3-layered cardboard, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

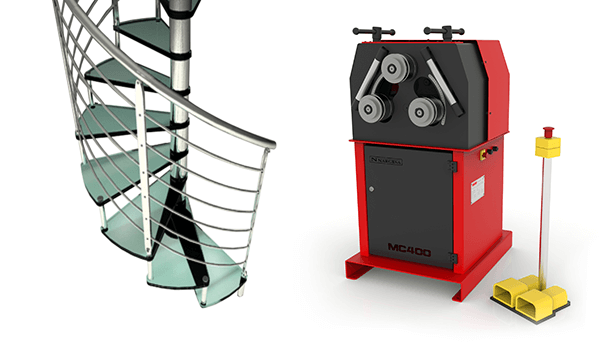

Uses of the machine Non-mandrel tube and pipe bender CC90 CNC

Fixed radius bending machines are used in most branches related to the world of metallurgy. Naval: to build all types of ducts and pipes with different shapes. For the protections and rails of yachts in stainless steel. Construction: for all types of stairs, pool railings, parking protections, gas stations, pillars, boats... Automobile: bumpers, anti-roll bars, protections and windows of "buggies"... Motorcycle: motorcycle chassis, handlebars, motorbikes and bikes parking. Furniture: Manufacture of workout machines, chairs, tables and all kinds of furniture. Agriculture: Structures for animal feeders, machinery, greenhouses... Manufacturing of heat exchangers in copper, aluminum, brass, bronze, iron, steel... especially ideal for bending coil heat exchangers.