Industrial sheet metal bending: Types and characteristics

Sheet metal bending is an essential manufacturing process in the metalworking industry that involves deforming a sheet of metal, commonly called sheet metal, to obtain a specific angle or shape. This process is used to create a wide variety of metal products and components, from simple parts such as brackets to complex structures such as vehicle bodies and machinery components. Before starting to work with a Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003CNC, it is essential to understand the different types of bending.

Types of sheet metal bending

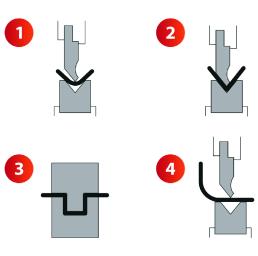

1. Air Bending

Air bending is the folding process performed on the die without the folded sheet reaching the bottom of it. In other words, when the punch reaches its lowest position, there is a gap or an air space beneath the sheet, between it and the die. This allows for obtaining different bending angles using the same tools, which requires working with extreme precision to ensure a perfect result.

Since the introduction of CNC technology to the Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003CNC, the most frequently used bending method is air bending or partial bending. During any bending process, the sheet experiences elastic springback as soon as we stop applying pressure to it. Thanks to CNC, the air bending technique estimates the degree of this springback and lowers the punch while taking this factor into account.

There are two fundamental aspects that must be controlled when performing this type of bending: The position of the sheet upon lowering and the pressure exerted on the material. These two concepts are vital for effectively utilizing this bending technique.

Advantages of Air Bending

- Greater Range of Bending Angles: This technique allows for a wider range of angles in folded pieces using the Hydraulic press brake Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003 CNC. With a tooling kit (punch and die) set at 30°, any angle between 30° and 180° can be achieved through air bending.

-

Faster Execution: Air bending is faster, as achieving a sharper angle only requires lowering the punch by a few millimeters. In contrast, other techniques may require more pressure or increased dwell time for the sheet.

-

Lower Pressure Requirement: The necessary pressure is lower than in other working methods.

-

Reduced Friction: The sheet experiences fewer marks due to the limited friction surface with the die.

-

Less Wear and Tear: Punches and dies have an increased lifespan.

-

Lower Tonnage Requirement: A folding machine with lower tonnage is needed compared to the tonnage required for the same bending using another technique.

Disadvantages of Air Bending

-

Reduced Bending Precision: The precision of the bending angle is lower compared to other bending methods. The precision is approximately within +/- 1 degree.

-

Elastic Springback: This technique works with elastic springback, but it doesn't eliminate it. For this reason, it's a challenging technique to use for working on large radii or pieces with significant springback.

2. Bottom Bending

Bottom bending is the folding process performed on the die, pressing the sheet with the punch until it reaches the bottom of the die. The resulting bending angle depends on the punch and die used.

With the bottom bending technique, the sheet comes into contact with the bottom of the V of the lower die. This technique is preferred when aiming for greater precision in both the bending angle and the radius of the profile to be folded.

Precision increases because the sheet is formed with lower support, allowing for a more uniform radius at the bend's tip and a more substantial reduction in elastic springback. This ultimately results in a more accurate bend.

For this bending method, it is essential to choose the appropriate punches and dies. The angle and opening of the tools must be precisely calculated to achieve the desired profile, taking into account the elastic springback that the sheet will exhibit.

The punch and die should have the same angle to achieve a better force distribution on the sheet between both sides.

Advantages of Bottom Bending

-

Lower Pressure: Achieve good precision with lower pressure on the Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003 CNC.

-

Mass Production: Increased part repeatability for long production series.

-

Reduced Elastic Springback

-

Less Deformation in Punched Sheets: Holes near the bending zone are less deformed. This deformation is partially corrected as the sheet is pressed between the tools.

-

Higher Precision: Approximate tolerance of 1/2 degree.

Disadvantages of Bottom Bending

-

No Corrections Allowed: It's impossible to correct errors in the bending angle result, as the tools are at their maximum capacity. The punch cannot be lowered further.

-

Limited Range of Angles: This technique is only used to obtain angles between 80° and 90°.

- Need for More Tooling: Specific tools are required for each specific bending job.

-

Increased Friction: Lower aesthetic quality of bent parts due to higher friction between the sheet and the die.

3. Stamping

Stamping allows folding the sheet onto itself to provide more strength to specific areas.

The stamping technique gets its name from the process by which coins are stamped. This is because the stamping process enables the creation of pieces that are perfectly identical to each other, much like coins.

However, the stamping process requires a very high pressure relative to the thickness of the sheet. This technique necessitates a force 4 to 5 times greater than the pressure used in air bending. The tools used in the stamping process must have the exact angle desired for the sheet piece. In fact, the force demanded by the process is necessary to overcome the elastic springback of the sheet, thereby "imprinting" or "stamping" the shape of the tools onto the sheet. Clearly, this is a continuous process, but it's limited to specific thicknesses and certain folding machines.

Advantages of Stamping

- Consistent Outcome

- Tolerance of 1/4 of a degree

- Ability to achieve Minimal Radii in Bent Parts

Disadvantages of Stamping

- Reduced Lifespan of the Folding Machine and Tools

- Increased Friction: Poor aesthetic result of the bent sheet due to high levels of friction.

- Need for More Tooling: Each sheet thickness requires a different punch and die, respecting the angle, radius, strength, and opening of the die.

- Only for Thin Sheet Thicknesses: It's impossible to use this technique for sheet thicknesses greater than 2mm, as the necessary pressure would be excessively high.

4. Sheet Bending or Rolling

This type of bending is a variation of air bending that allows for different curvature radii of a sheet through multiple sequential bends performed on the same sheet. The outcome of this type of bending is an angle with a larger or smaller radius.

Thanks to the CNC capabilities of the Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003 CNC, we can program this type of bending by inputting the curvature radius, the distance between bends, and the angle. The choice of this distance depends on the desired finish; a smaller distance between bends results in better curve definition. With these data entered, the CNC takes care of the necessary calculations to determine the bending angles at each step, resulting in the final curved shape.

Advantages of Sheet Bending or Rolling

-

Capability for Bending: Although sheet metal folders are not the ideal machines for sheet bending, this type of folding allows us to achieve bends very close to a crease that wouldn't be possible otherwise.

-

Wide Range of Bending Radii: This technique enables a wide range of curvature radii in the bent pieces. With a tooling kit (punch and die) set at 30°, using these bending sequences, any curve from 0° to 90° can be achieved.

-

Lower Pressure Requirement: Less pressure is needed compared to other working methods because multiple small-angle bends are performed, requiring less force.

-

Reduced Friction: The sheet experiences fewer marks due to the minimal friction surface with the die and the lower punch pressure.

-

Less Wear and Tear: Punches and dies have an extended lifespan

Disadvantages of Sheet Bending or Rolling

-

Perception of Bends: Unlike sheet bending, rolling through multiple folds doesn't provide the same smooth finish in the final result. The bent sheet using this technique can show the creases.

-

Elastic Springback: This technique works with elastic springback, but it doesn't eliminate it. For this reason, it's challenging to use this technique for working on large radii or pieces with significant springback.

To learn more about different folding techniques, choosing punches and dies, CNC programming, interpreting bending tables, factors to consider for optimal bending, and much more, you can watch the video tutorial on folding using the Hydraulic press brake MP1500CNC and Hydraulic press brake MP3003 CNC.

Leave a comment

Join to our Newsletter

Be part of our Nargesa Community and get all information of the branch, demo clips, campaigns in Machinery…

Comments

Banding machine

Muhammad Faisal - Mon, 07/08/2024

I am interested in your machine kindly send the complete pictures and detail and prices.

+923218289180

My watsup & wechat number

Re: Banding machine

Nargesa - Mon, 07/08/2024

Hello Mr. Muhammad Faisal

We will send you the catalog of these machines in less than 24 hours.

Thank you for contacting us

Press brake bending

Ginni - Wed, 07/31/2024

Informative blogs

Re: Press brake bending

Nargesa - Wed, 07/31/2024

Hello Mr. Ginni

Our sales department will send you the data sheet for this machine, today.

Thank you for contacting us

Hola, estoy interesada en la…

andry alvarez - Fri, 08/23/2024

Hola, estoy interesada en la maquina me gustaria obtener el catalogo y ficha tecnica de la maquina

Re: Hola, estoy interesada en la…

Nargesa - Fri, 08/23/2024

Buenos días,

Muchas gracias por contactar con nosotros. Nuestro departamento comercial le enviará el catálogo y la ficha técnica de los dos modelos de plegadoras que fabricamos.

Saludos cordiales,