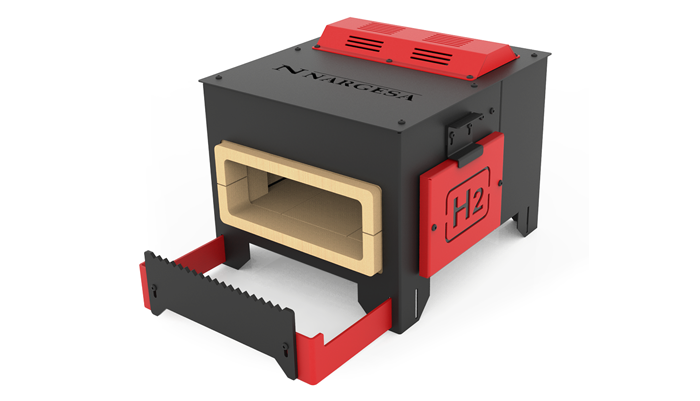

New Generation of PV21 Hot Forging Presses, easier to operate, more precise, quieter, safer, and with many other features

In collaboration with some of the best blacksmiths in Spain, France and the United States, the Prada Nargesa engineers have designed a forging press with all sorts of features. Easier to handle, more accurate, more silent, safer and with many more features that make it the best choice among all the presses currently available on the market as more than 90% of the others unfortunately do not even comply with EC regulations.

All Nargesa products are adapted to EC industrial machinery manufacturing standards.

.

Our customers say

Technical features

The PV21 hydraulic hot forging press is essential to any metal forming process. Designed for demanding use, it combines robustness and precision to offer optimal performance when forging many different types of materials. This section details the key technical characteristics that make the PV21 an outstanding choice for metal forging.

- Operating power: 21 metric tons / 23 US tons

- Stroke: 296 mm / 11.65”

- Useful table surface: 250 mm x 260 mm / 10” x 10.2”

- Repetitiveness: 0.03 mm / 0.001”

- Operating speed: 13 mm/s

- Reverse speed: 75 mm/s

- 22 blows per minute over a 15 mm stroke

- Operating height: 1020 mm / 40”

- Means of operation: Vertical drop for absolute control and the utmost precision.

- Table guided with four 55 mm chrome-plated columns with nothing that alters the results.

- Power: 2.2 kW / 3 CV

- Voltage: 230/440 V three-phase 50/60 Hz

- 220 v single-phase voltage OPTIONAL

- Intensity: 9/5 A

- Built-in pressure gauge.

- Quick start-up: The machine is shipped fully assembled. It just needs to be connected to the grid.

- Manual and automatic operation, to increase productivity to the max.

- Top and bottom limit switches, to eliminate all unnecessary movement.

- Near-zero noise level

- Near-zero maintenance.

- Mobile safety pedal.

- Height and orientation adjustable protection on the front and back.

- Electric engine protection.

- Emergency stop.

- CE marking.

- Standard mold: 130 mm x 80 mm

- Can work with two side molds simultaneously.

- Mold switch time: 45 seconds.

- Self-centering molds which can rotate 90º for parts of all sizes.

- Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures.

- Great variety of tooling and exchangeable molds.

- Custom-manufactured molds.

- A lower pallet bench to easily move the machine to the worksite or storage.

- Standard packaging on a wood pallet, in a 3-layer cardboard box suitable for maritime transport.

- Optional: NIMF15 wooden packaging.

Here are some of the advantages that make us stand out over the competition and should be considered before buying a forging press.

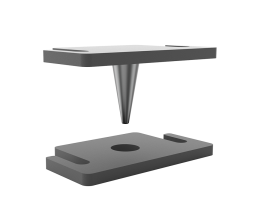

MACHINED TABLE, GUIDED BY 4 COLUMNS WITH A HOLE IN THE MIDDLE

The press table is machined, which ensures it’s perfectly parallel unlike most presses on the market which are guided by beams or lateral iron structures that don’t guarantee parallelism or accuracy during the drop.

The PV21 press is guided with four 55 mm chrome-plated columns to ensure nothing alters the sides.

The 40 mm or 1.57” hole in the middle makes it easier to hot punch directly on the table without needing any tooling on the bottom. There is a box on the inside to collect any material fragments that may come off during the process.

VERTICAL DROP

Many presses operate upwards, forcing operators to move their arms up and down while guiding the piece. This makes the process even more difficult and is by no means necessary for good work. On the contrary, the PV21 forging press drops vertically, always keeping the piece secure on the bottom table which facilitates and speeds up the hot forging work.

MANUAL AND AUTOMATIC OPERATION

When in manual mode, the press only drops when the pedal is pressed down. It remains in a fixed position as soon as the operator’s foot is lifted. This means of operation is particularly useful when doing very delicate work or to center a custom mold.

With automatic operation, the machine drops to the lower limit switch or until the operator’s foot comes off the pedal. Then, it automatically moves up to the top limit switch. If the pedal is pressed down, the press drops and rises repetitively to each limit switch, which can be adjusted to delimit the movement to the minimum necessary for each specific job. This boosts productivity.

TOP AND BOTTOM LIMIT SWITCHES

Many modern presses are activated with a side lever with no limit switches, which means operators always have their hand busy. This makes it quite difficult to make two similar pieces.

To overcome this problem, the PV21 press features 2 adjustable limit switches on one side. The top limit switch allows you to adjust the top position, leaving the opening just right for more productive work. The bottom limit switch controls the final press position, making all the work much easier. With repetitiveness less than 0.03 mm or 0.0001”, the PV21 is the most accurate and precise forging press in the world and is ideal for producing Damask knives and swords.

VERSATILITY

The large work table and 250 mm x 296 mm, or 10” x 10.2” opening make it so operators can work with two molds next to each other at the same time. This is particularly useful for producing knives, swords and forged items like hammers, pliers, etc.

All molds are self-centering for easier error-free positioning. It takes no more than 60 seconds to switch any of them.

All the tooling can be fixed horizontally or vertically. The design of the holes in the table makes it possible to use the same mold, rotating it 90º, which is highly useful when forging swords or large-sized items.

EASY CUSTOM MOLD PRODUCTION

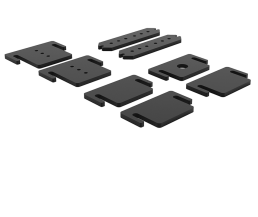

There are no limits to the types of jobs that need to be done meaning you often have to customize molds to save time and money. Prada Nargesa supplies the machine with two additional sets of self-centering plates to weld or screw on any type of custom mold.

SAFETY AND CE MARKING

The PV21 has a safety pedal with a fold-down tongue which prevents the machine from being accidently started. The machine is also equipped with front and back adjustable protective devices that lower the possibility of getting hit with fragments without losing visibility at any time. Plus, the emergency stop button, which is fully accessible throughout the work, and other complementary safety mechanisms make the PV21 forging press more than compliant with all EC machinery manufacturing standards.

Unfortunately, many of the presses on the market nowadays are not compliant with the regulations in various countries. The safety of our operators and all people must be a top priority for everyone.

Optional accesories for Hot Forging Press PV21

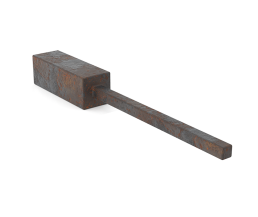

Press mold 21

Pyramid-shaped molds to form the material and stretch it faster.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures. This material maintains its mechanical properties at high temperatures.

REF: 140-18-01-00021

Mold dimensions: 130x80x67mm

Weight: 6.10kg

Optional tooling

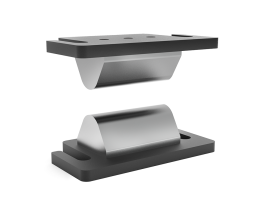

Press mold 22

Molds with a rounded surface to stretch material without excessive deformation.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures. This material maintains its mechanical properties at high temperatures.

REF: 140-18-01-00022

Mold dimensions: 130x80x67mm

Weight: 7.20kg

Optional tooling

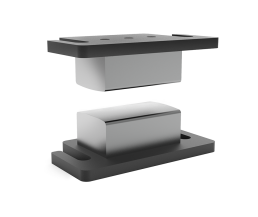

Press mold 23

Flat molds to flatten material with small radius edges, to create steps.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures. This material maintains its mechanical properties at high temperatures.

REF: 140-18-01-00023

Mold dimensions: 130x80x67mm

Weight: 7.30kg

Optional tooling

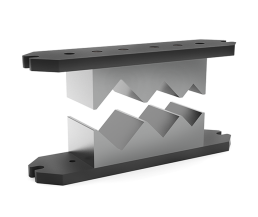

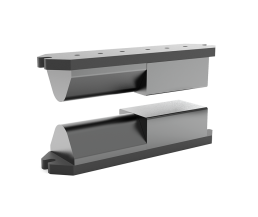

Press mold 24

Dies with three V-shaped slots (2”, 1” 1/2 and 1”) for pressing steel. Specially designed to avoid changing tools by unifying three sizes in the same tool. Ideal for manufacturing parts with Damascus steel.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures. This material maintains its mechanical properties at high temperatures.

REF: 140-18-01-00024

Mold dimensions: 325x80x67mm

Weight: 14,5 Kg

Optional tooling

Included accesories for Hot Forging Press PV21

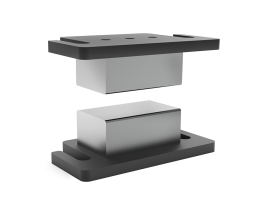

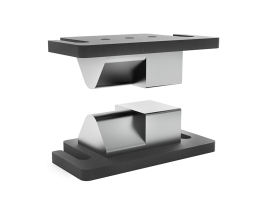

Press mold 20

Molds with two work areas to stretch and flatten material. Highly versatile.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major effort and high temperatures. This material maintains its mechanical properties at high temperatures.

REF: 140-18-01-00020

Mold dimensions: 130x80x67mm

Weight: 6.60kg

Standard tooling

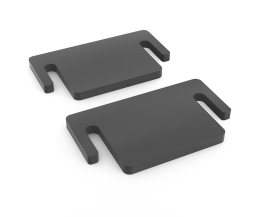

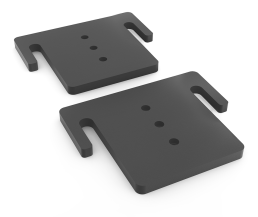

Single base PV21

Two bases to be able to weld or screw any mold manufactured by the customer, as per the work needs.

Bases made of F-111 steel.

REF: 140-18-01-00001

Mold dimensions: 230x135x15mm

Weight: 6.10kg

Standard tooling

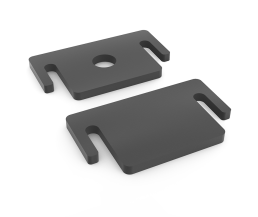

Base with hole in the middle PV21

Two bases to be able to weld or screw any mold manufactured by the customer, as per the work needs. These bases were designed for hot punching.

Bases made of F-111 steel.

REF: 140-18-01-00004

Mold dimensions: 230x135x15mm

Weight: 6.00kg

Standard tooling

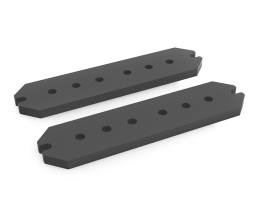

Front-assembly base PV21

Two bases to be able to screw any of the molds we manufacture together, perpendicular to their original position.

Bases made of F-111 steel.

REF: 140-18-01-00005

Mold dimensions: 230x185x15mm

Weight: 7.60kg

Standard tooling

+ Info for Hot Forging Press PV21

At Prada Nargesa, we believe every single professional has their own needs. And that’s why we’ve created a versatile system of bases which come with each machine, enabling our customers to design and manufacture their own molds quickly and efficiently. With these bases in different shapes, sizes and securing systems, we provide everything needed to secure these custom molds to the machine table. This flexibility not only saves time and costs, but also boosts creativity and adaptability in the forging process.

At Nargesa, we’re committed to offering solutions that don’t just satisfy our customers’ expectations but rather exceed them.

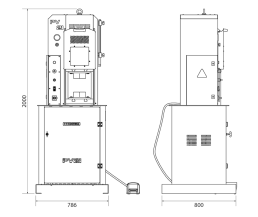

Dimensions of the machine Hot Forging Press PV21

Characteristics of the packaging Hot Forging Press PV21

Uses of the machine Hot Forging Press PV21

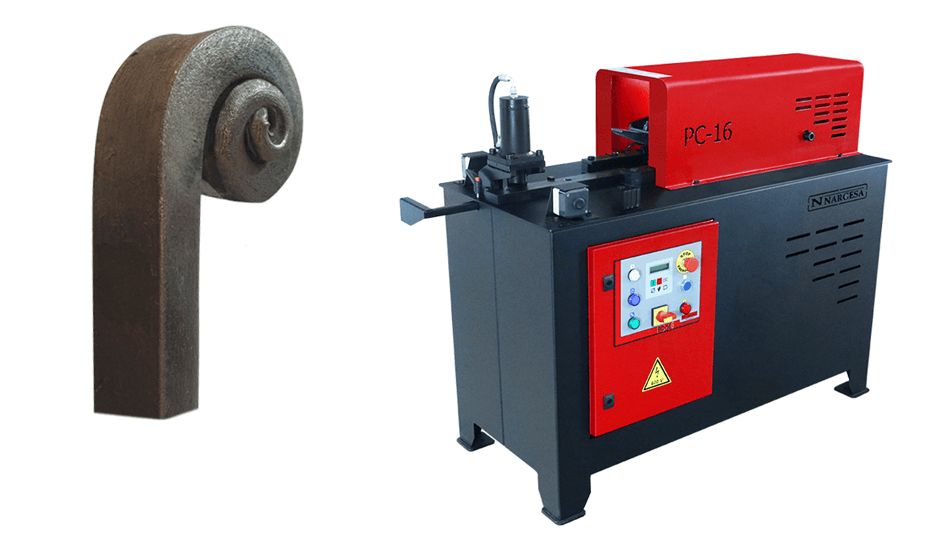

The PV21 hydraulic forging press can create a wide variety of metal pieces with a pressurized hot forming process:

- Swords and knives: Precisely forged edged tools and weapons.

- Hot welds: Particularly used to weld damask and all types of steel.

- Horseshoes: Essential pieces for horse care, forged for resistance and durability.

- Spear tips: Historically used as weapons and hunting tools. These tips are now placed on metal bars, gates, forged fencing...

- Ornamental components: Railings, pergolas, bars, furniture, sculptures, doors, support bases, shelving...

- Forging tools: Forging clamps or pliers, blacksmith tongs, V-shaped fish mouth pipe cutter...

- Sculptures: From small decorative pieces to large artistic set-ups.

- Decorative craftwork: From lamps and light fixtures to chandeliers, designed with fine details and for durability.

- Old farming tools: Hoes, axes and sickles, optimized for field work.

These examples highlight the versatility of this hot forging press when creating pieces that are as functional as they are decorative, taking advantage of its capacity to shape metals with precision and resistance.