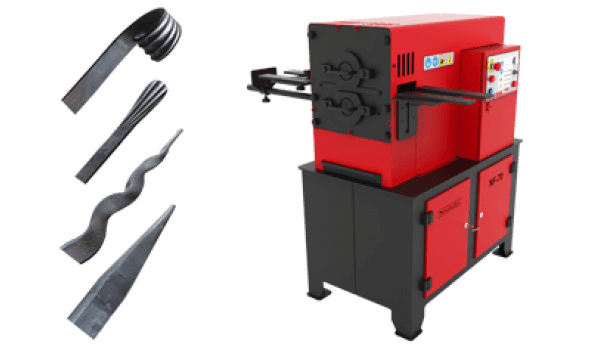

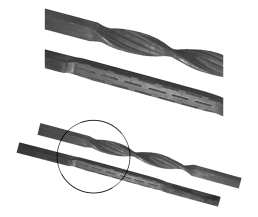

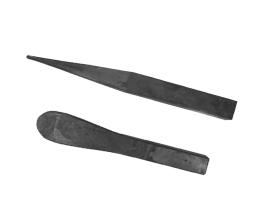

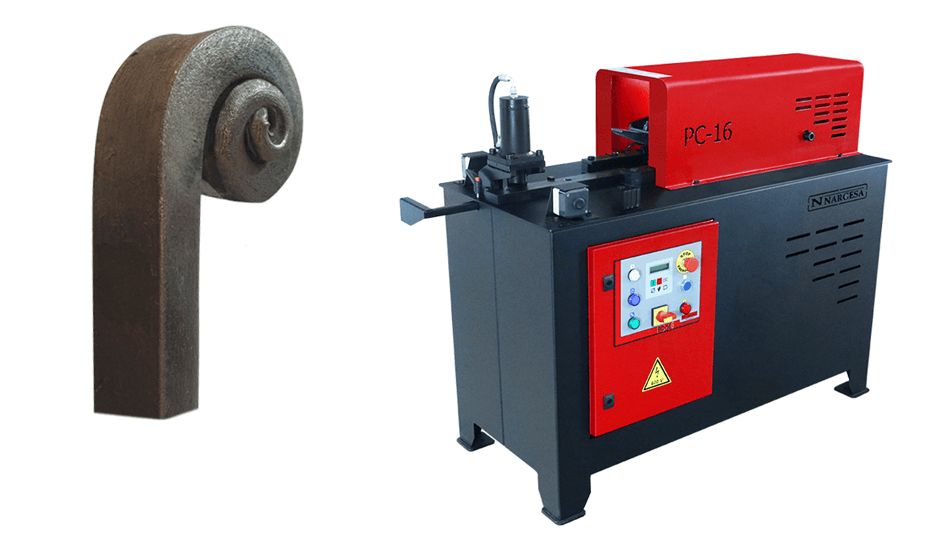

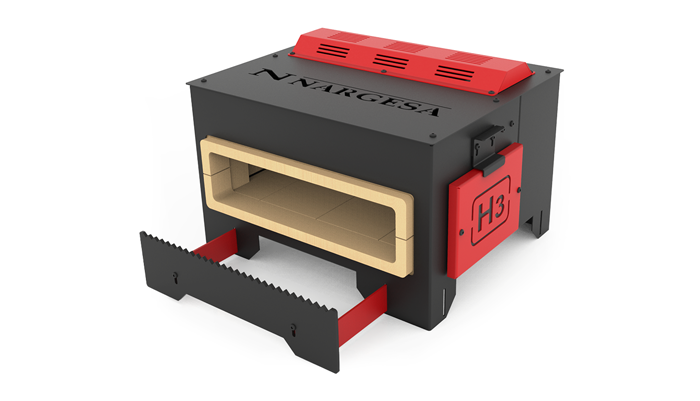

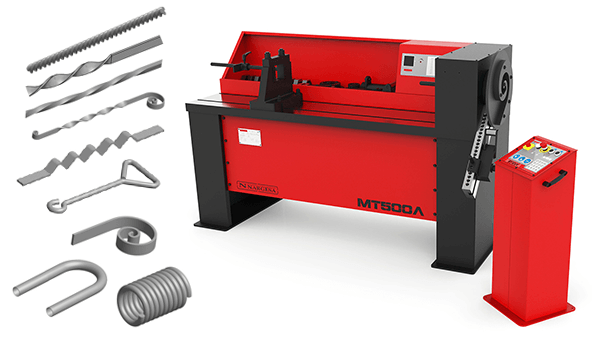

The End Hot Wrought Iron Machine Nargesa NF70, shapes up the arrow ends, flat ends, striated ends, etc.in either round, square or different sizes flat bars.

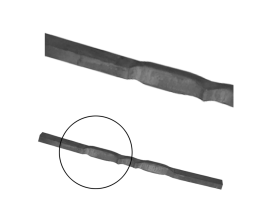

The Wrought iron Machine Nargesa NF70 smashes and molds irons up to obtaining the desired shape depending on the mold design. It forges arrow ends or lances of different kinds; flat, pyramidal, etc. It also makes baluster extremes to accomplish nice ornamental parts by changing the die. It forges and smashes balusters in the middle to make different designs.

All Nargesa products are according to the CE regulations for the manufacturing of industrial machinery.

Our customers say

Technical features

Maximum capacity in round: Mild steel round of 20 mm.

Maximum capacity in square: Mild steel square of 20 mm.

Maximum capacity in flat bar: Mild steel flat bar of 40x10 mm.

Digital screen.

Turns programmer.

Rotation speed: 20 rpm.

Adjustable back gauge.

With standard accessories wrought ends, flat ends, striated and pyramidal ends can be made. (See STANDARD TOOLING below).

OPTIONAL ACCESSORIES (See below) If the customer asks for it, we make molds under request.

Engine power: 5,5 KW/ 7 CV (HP).

Three phased tension: 230/400 V.

For other tension or single phased machines, please ask the manufacturer.

Palletized lower bench to easily move the machine up to its working place or storage.

The machine is sent completely mounted.

Packaging with a wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

Optional: Complete wooden packaging with fumigated wood NIMF15.

ADVANTAGES:

- Easy handling: Any worker is able to carry out this job, even without any previous preparation.

- Readiness: Thousands of parts can be made in a sole working day.

- Value and prestige: There are few craftmen who can make this kind of wrought jobs.

- Sales: Possibility of selling parts with the forged extremes to different companies or steel stores.

All or products are manufactured in our facilities in Spain. The hydraulic and electrical components are all standard from the best leading European trademarks, with technical assitence all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Optional accesories for End Hot Wrought Iron Machine NF70

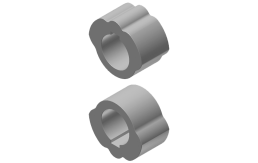

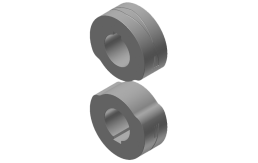

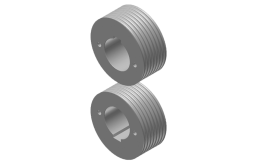

Set of trilobular rollers

REF: 140-12-02-00003

MAXIMUM CAPACITY: Round and square 20mm.

MAXIMUM CAPACITY: Rectangular 50x10mm.

UNITS PER SET: 2 units.

WEIGHT: 4,2 Kg each unit.

Optional tooling.

Set of triple middle marking rollers

REF: 140-12-02-00004

MAXIMUM CAPACITY: Round and square 20mm.

MAXIMUM CAPACITY: Rectangular 50x10mm.

UNITS PER SET: 2 units.

WEIGHT: 8,5 Kg each unit.

Optional tooling.

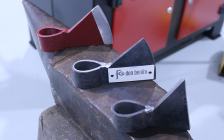

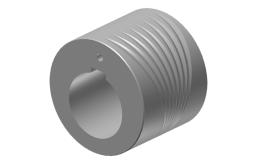

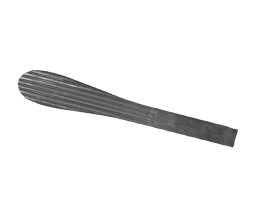

Set of fishtail rollers

REF: 140-12-02-00005

MAXIMUM CAPACITY: Round and square 20mm.

MAXIMUM CAPACITY: Rectangular 50x10mm.

UNITS PER SET: 1 unit.

WEIGHT: 7,7 Kg each unit.

Optional tooling.

Included accesories for End Hot Wrought Iron Machine NF70

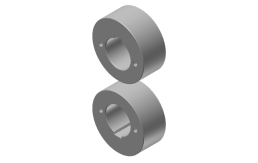

Set of flat rollers

REF: 140-12-02-00001

MAXIMUM CAPACITY: Round and square 20mm.

MAXIMUM CAPACITY: Rectangular 50x10mm.

UNITS PER SET: 2 units.

WEIGHT: 4,2 Kg each unit.

Standard tooling.

+ Info for End Hot Wrought Iron Machine NF70

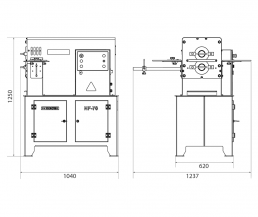

Dimensions of the machine End Hot Wrought Iron Machine NF70

Characteristics of the packaging End Hot Wrought Iron Machine NF70

Nº Pallets: 1.

Width: 1120 mm.

Depth: 1120 mm.

Height: 1500 mm.

Volume: 1,88 m3

Nett Weight: 493 Kg.

Gross Weight: 540 Kg.

Tarif Code: 84622290

Other features:

- Palletized bench to move it easily to its working site or storage.

- The machine is sent completely assembled.

- Packaging with wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine End Hot Wrought Iron Machine NF70

The End Hot Wrought Iron Machine Nargesa NF70 forges iron to make all kinds of shapes with different designs: Arrow ends, lance points, flat or striated extremes for volutes, central cast in balusters…These ornamental pieces are used to make gates, fences, windows, doors, headboards for beds, metal furnishing, etc…