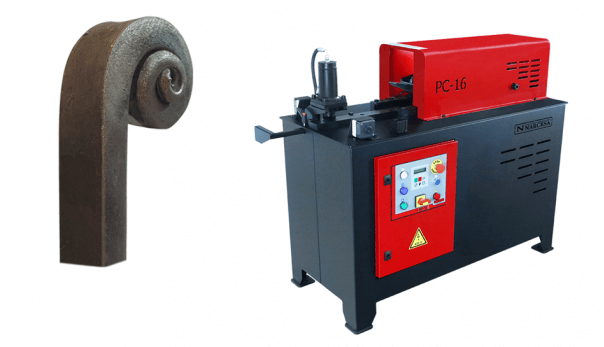

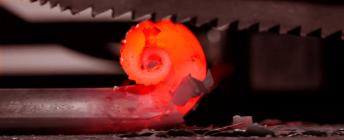

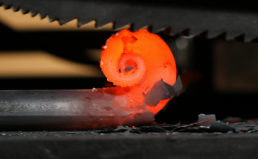

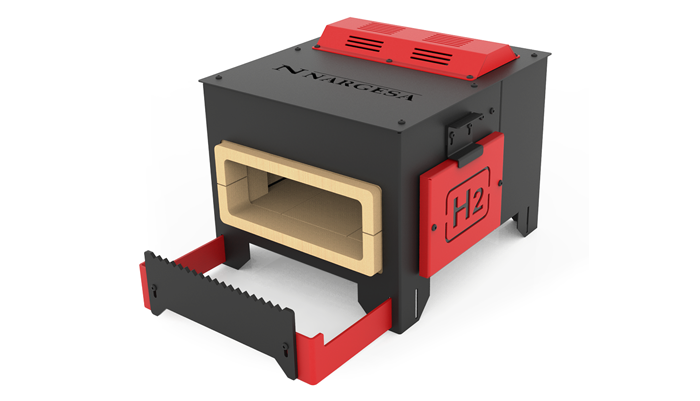

The End Hot Wrought Machine Nargesa PC16, makes snails shaped extremes in round bar, square bar and flat bars of different sizes...

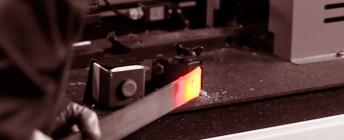

The End Hot Wrought Machine Nargesa PC16, eases up the rolling job of hot steel. It rolls up the snail forged shaped end. This decorations are commonly used as extremes in scrolls and decorative parts.Gates, windows, fencing, metal furniture, etc...

All Nargesa products are according to the CE regulations for the manufacturing of industrial machinery.

Technical features

- Adjustment of displacement or turns.

- Adjustment of pressure according to material thicknes.

- Safety double command for the cycle drive.

- Hydraulic clamp for the piece fastening.

- Maximum capacity in round: 20 mm.

- Maximum capacity in square: 20 mm.

- Maximum capacity in flat bar: 50x10 mm.

- Working speed: 45 mm/s.

- Return speed: 70 mm/s.

- Cycle time: 10 secodns.

- Pieces per minute: 4 pieces.

- Engine power: 2,2 KW/ 3 CV (HP).

- Three phased tension: 230/400 V.

- For other tension or single phased machines, please ask the manufacturer.

- Palletized lower bench to easily move the machine up to its working place or storage.

- The machine is sent completely mounted.

- Packaging with a wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging with fumigated wood NIMF15.

ADVANTAGES:

- Easy handling: Any worker is able to carry out this job, even without any previous preparation.

- Readiness: Thousands of parts can be made in a sole working day.

- Value and prestige: There are few craftmen who can make this kind of wrought jobs.

- Sales: Possibility of selling parts with the forged extremes to different companies or steel stores.

All or products are manufactured in our facilities in Spain. The hydraulic and electrical components are all standard from the best leading European trademarks, with technical assitence all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

+ Info for End Hot Wrought Iron Machine PC16

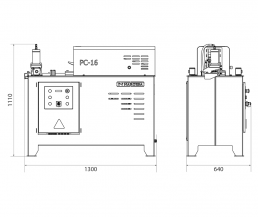

Dimensions of the machine End Hot Wrought Iron Machine PC16

Characteristics of the packaging End Hot Wrought Iron Machine PC16

Nº Pallets: 1.

Width: 1350 mm.

Depth: 680 mm.

Height: 1280 mm.

Volume: 0,93 m3

Nett Weight: 336 Kg.

Gross Weight: 355 Kg.

Tarif Code: 84622900

Other features:

- Palletized bench to move it easily to its working site or storage.

- The machine is sent completely assembled.

- Packaging with wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine End Hot Wrought Iron Machine PC16

The Hot Wrought Machine Nargesa PC16, rolls up hot steel making a snail shaped extreme. It is used to create scrolls and designs for ornamental forging in doors, windows, gates, metal furniture, etc...