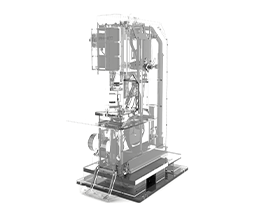

The Power Hammer PH50 with compressor incorporated, to make all kind of pieces for the ornamental forging. It's got 50 kg stroke.

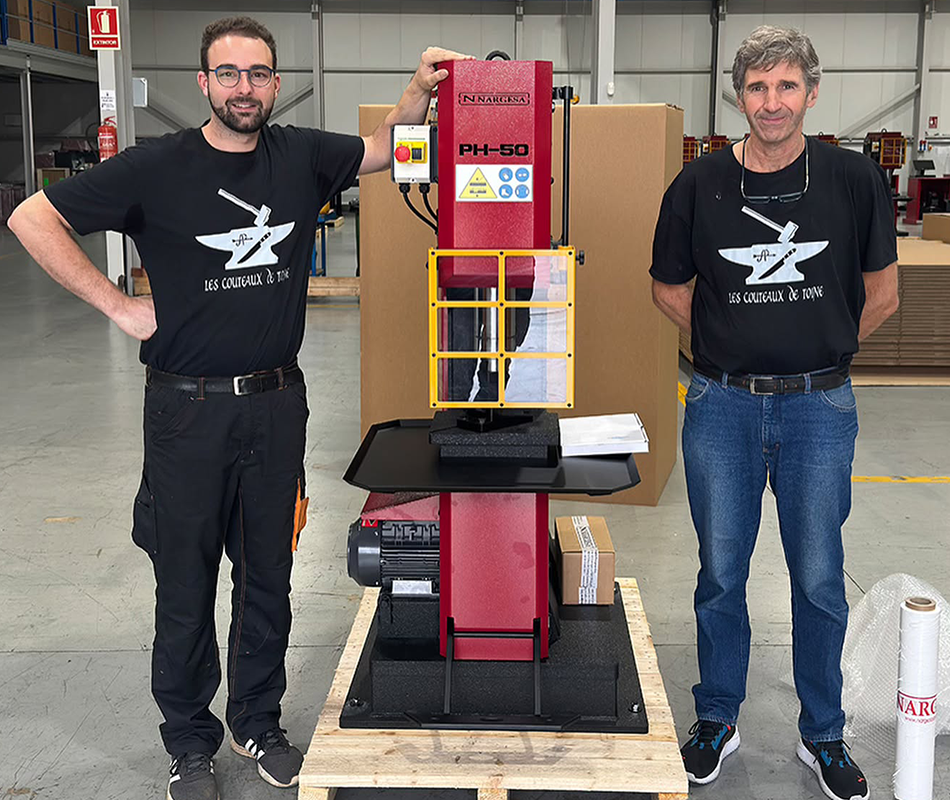

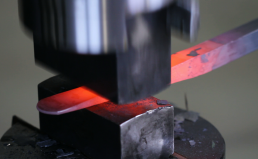

Power Hammers PH50 Nargesa, are manufactured in welded and mechanized steel sheet. It is used in many blacksmith workshops to make all kinds of parts for the ornamental forging, which eases the job of moulding hot iron. Different tooling are used with it to inlay, mould, give shape, cut, pierce, rivetting and embossing, etc all kinds of metal. In collaboration with some of the best blacksmiths in Spain, France and the United States, the Prada Nargesa engineers have designed a power hammer with all sorts of new advances in comparison to the other drop hammers on the market up until now. Easier to manage, more precise, safer, quieter and with no need for any civil engineering work for installation in addition to many other features, it’s the best choice available. All Nargesa products are adapted to the CE standards for the manufacture of industrial machinery.

Our customers say

Technical features

The Drop Hammer PH50 Nargesa works by two cylinders, one at the back and another one at the front which is the one that impulses the stem for the stroke. The motor for the powerhammer moves the rod of the back cylinder or compressor and the compressed air goes to the front cylinder through the valves that control the stroke displacement.

- Built-in compressor.

- Maximum drop precision, controlled via a next-generation valve.

- Welded and die-cut steel frame.

- Automatic greasing system.

- Lapped cylinders designed with low-friction technology.

- Intake and exhaust mufflers.

- No need for civil engineering work or special foundations for installation.

- Automatic inner ventilation.

- Inner tray to collect greasing oil.

- Near-zero maintenance.

- Double mechanical stop protection.

- Height and orientation adjustable protection on the front.

- Drive system pedal protection.

- Electric engine protection.

- Emergency stop.

- CE marking.

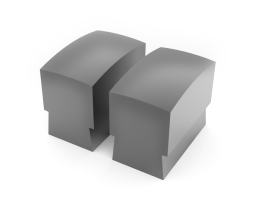

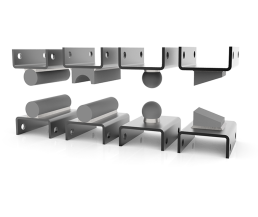

- Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

- The power hammer can be moved with a forklift or a lifting hook.

- Great variety of tooling and exchangeable molds.

- Custom-manufactured molds.

Technical Features

- Nominal dropping weight: 50 kg / 110 lb

- Strokes per minute: 240

- Ram range: 180 mm / 7”

- Operating range: 220 mm / 9”

- Maximum round working capacity: 70 mm / 2.75”

- Maximum square working capacity: 60x60 / 2.36”

- Engine power: 2,2 kW / 5,5 HP

- Electrical voltage: 230/400 V three-phase 50/60 Hz

- Single-phase: 220 V voltage OPTIONAL

- Intensity: 18/10 A

- Weight: 1002kg

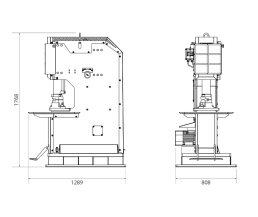

- Dimensions: 808x1289x1768mm

The machine is sent completely assembled.

Packaging with wooden pallet and cardboard box.

Optional: Complete wooden packing NIMF15.

All our products are manufactured in our facilities in Spain. Hydraulic and electric components are completely standard from the best European leading trademarks, with technical support all over the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc...

Before purchasing a Power Hammer...

Before purchasing a power hammer, a few basic details are needed before making a final decision:

- BUILT-IN COMPRESSOR: The PH50 power hammer has a built-in compressor. This means, unlike with other brands, no external compressor is needed. A 50 kg or 110 lb power hammer without a built-in compressor would need a 5 HP external compressor.

- NO NEED FOR SPECIFIC CIVIL ENGINEERING FOR INSTALLATION: Only 4 holes are needed in a concrete floor to insert the 4 chemical bolts that come with the machine when installing the PH50 power hammer.

- WELDED STEEL FRAME: The machine frame is not casted; it’s made of welded and die-cut steel. This reduces the possibility of cracking, as occurs with cast power hammers.

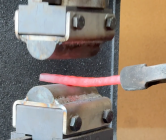

- MAXIMUM CONTROLLED DROP PRECISION: We achieved maximum precision with the ability to even close a box of matches or position an egg and collide with it without breaking it.

- LAPPED CYLINDERS DESIGNED WITH LOW-FRICTION TECHNOLOGY: The friction between the sleeve and piston is normally mechanical and through steel rings. This causes a risk of seizing up over time.

- INTAKE AND EXHAUST MUFFLERS: Two mufflers, on the intake and exhaust, reduce the noise to xx dB.

- AUTOMATIC LUBRICATION SYSTEM: The lubrication system on the PH50 power hammer features a completely transparent tank next to the power switch to monitor the level of oil in the container without having to use uncomfortable inspection peepholes.

- DOUBLE MECHANICAL STOP PROTECTION: The piston on the front and pedal become completely mechanically blocked in an ideal position to easily and safely change the molds.

- COLLECTING AND FILTERING OIL FROM THE AIR: The Nargesa PH50 drop hammer has a tank that collects this mix and separates the two components.

- SAFETY. CE MARKING: All of our machines are compliant with EC industrial machinery manufacturing standards.

Optional accesories for Power Hammer PH50

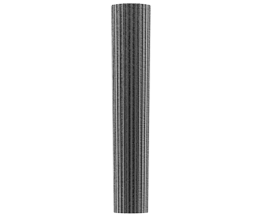

Oil SIL CN-20

REF: 060-BA-00030

High quality refined mineral oil, specially formulated for pneumatic circuits.

It provides optimum performance by lubricating and protecting components, ensuring smooth and efficient operation of pneumatic systems.

Ideal for extending machine life and reducing wear, this oil is a reliable solution for keeping the PH50 Power Hammer in perfect condition.

Container: 5L

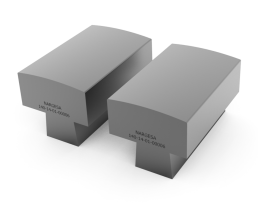

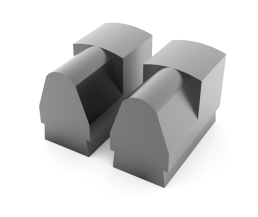

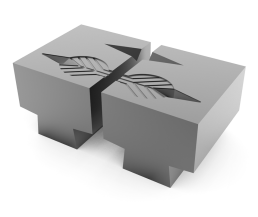

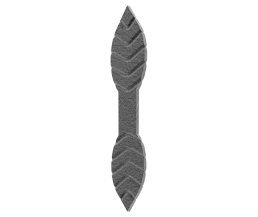

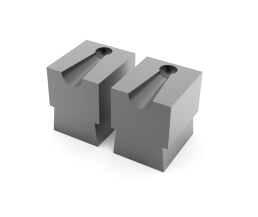

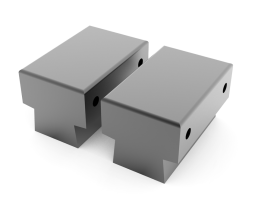

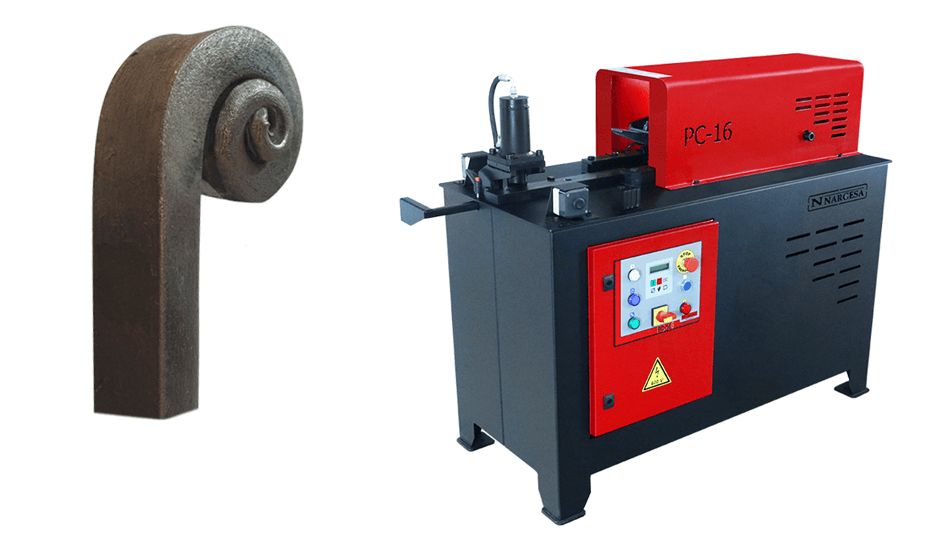

Tool for Power Hammer 04

REF: 140-14-01-00004

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 100x60mm

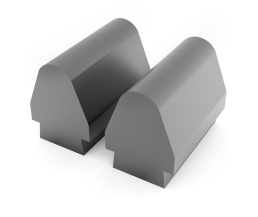

Tool for Power Hammer 06

REF: 140-14-01-00006

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x60mm

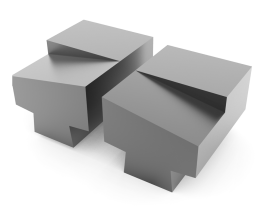

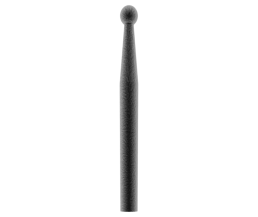

Tool for Power Hammer 07

REF: 140-14-01-00007

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x60mm

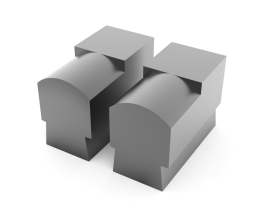

Tool for Power Hammer 08

REF: 140-14-01-00008

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 130x100mm

Tool for Power Hammer 09

REF: 140-14-01-00009

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x60mm

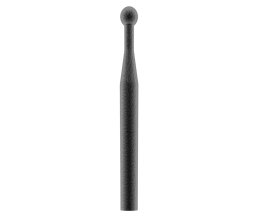

Tool for Power Hammer 10

REF: 140-14-01-00010

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x60mm

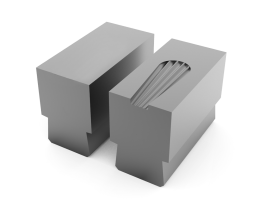

Tool for Power Hammer 13

REF: 140-14-01-00013

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x60mm

Capacity: 12mm round and 12mm square bar

Tool for Power Hammer 18

REF: 140-14-01-00018

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 160x80mm

Tool for Power Hammer 19

REF: 140-14-01-00019

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 130x80mm

Capacity: Ø12mm - 16mm - 20mm

Tool for Power Hammer 20

REF: 140-14-01-00020

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x100mm

Capacity: 12x12mm

Tool for Power Hammer 21

REF: 140-14-01-00021

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 120x70mm

Capacity: Ø 14mm

Tool for Power Hammer 22

REF: 140-14-01-00022

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 135x60mm

Tool for Power Hammer 23

REF: 140-14-01-00023

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 70x60mm

Capacity: Ø 16mm

Tool for Power Hammer 24

REF: 140-14-01-00024

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Nº of pieces: 2

Dimensions: 70x60mm

Capacity: 16mm round and 16mm square bar

Included accesories for Power Hammer PH50

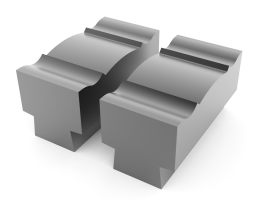

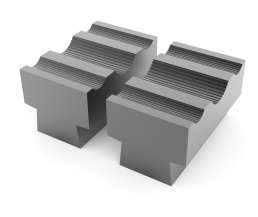

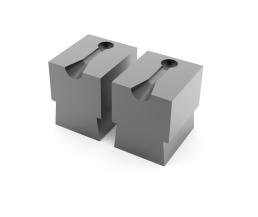

Standard flat mold for Power Hammer PH50

REF: 140-14-04-00001

All our Power-hammers are equipped with an upper standard flat tooling and lower one.

This tooling is the most versatile one.

Molds manufactured and tempered in 1.2344 steel / AFNOR: Z40CDV5 / DIN: X40CrMoV5-1 / UNE: F5318 / AISI: SAE H13 / SKD61 / 45Cr5MoSiV1 to withstand major impacts and high temperatures.

Standard tool

Nº of pieces: 2

Dimensions: 120x78mm

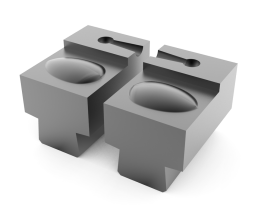

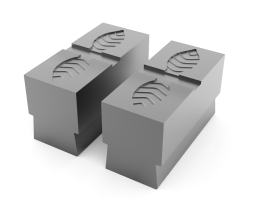

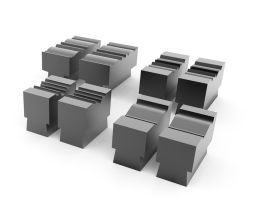

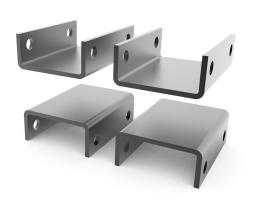

Support braces/ adaptors for Power Hammer PH50

REF: 140-14-04-00002

We supply two sets of Support braces along with the power hammer PH50.

These adaptors enable us to weld or fasten with bolts to them several kinds of elements, such as round and square solid bars, flat bars, rods etc… in order to manufacture our own tools.

Tools made of Steel F111.

Standard tool

Nº of pieces: 4

Dimensions: 120x89mm

+ Info for Power Hammer PH50

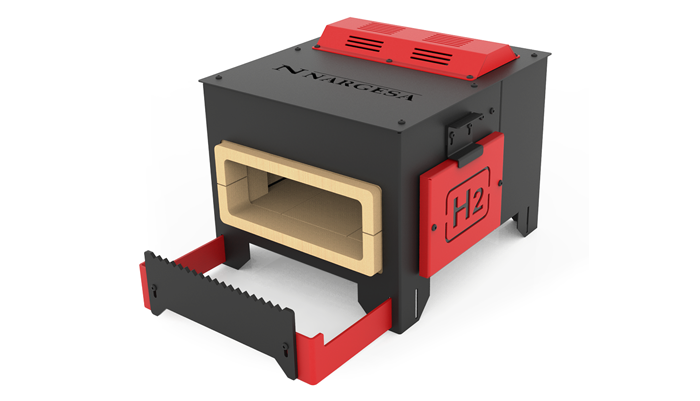

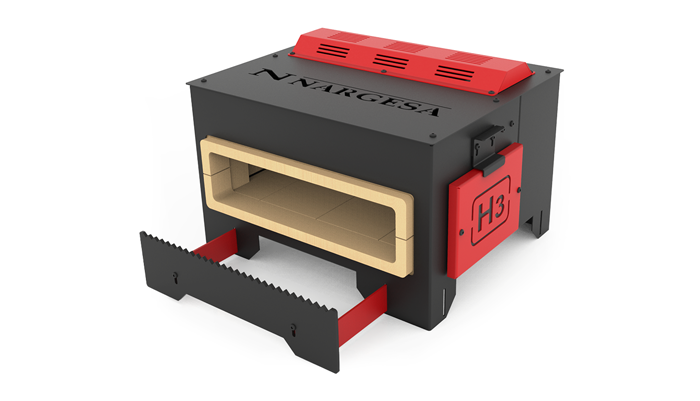

In order to have an optimal result in the different jobs, it is very important to have a good temperature in the part to be molded. Improve malleability, reduce resistance, prevent brittleness and improve stress distribution and fluidity. These aspects are essential during the deformation of metals. The Nargesa H1, H2 and H3 furnaces are manufactured to reach these high temperatures to accomplish a correct work. In addition, the new Nargesa PV21 Hydraulic Forging Press will allow you to hot-form materials, shape and manipulate metal efficiently and with impressive precision, such as for preparing Damascus for subsequent forging with the PH50 Nargesa hammer.

Dimensions of the machine Power Hammer PH50

Characteristics of the packaging Power Hammer PH50

Nº Pallets: 1

Width: 950 mm.

Length: 1430 mm.

Height: 1920 mm.

Volume: 2,60 m3

Nett Weight: 1002 Kg.

Gross Weight: 1088 Kg.

Tariff Item Code: 84621990

Other Features:

- The machine is delivered completely assembled.

- Packing with wooden pallet and retractile film.

- Optional: Complete wooden packaging NIMF15.

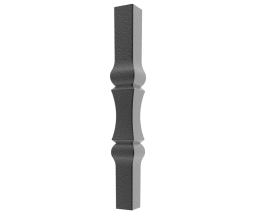

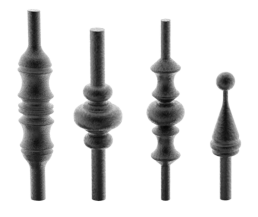

Uses of the machine Power Hammer PH50

The Nargesa PH50 Power Hammer is an essential machine for the metal sector, both for artistic forging and ornamental forging. It allows you to create decorative and functional pieces, with very diverse applications: Manufacture of knives, swords, tools for the restoration of antique furniture, windows, doors, restoration of ancient transport systems such as wagons, train cars, boats, manufacturing of bars, garden accessories such as flowerpots or outdoor furniture, arrowheads or spearheads to decorate wrought steel bars or portals, ornamental chandeliers, wrought iron fences, vintage bed headboards, decorative wrought iron coat racks, metal furniture, frames of mirrors, stretched tips for scrolls, vintage wrought iron lamps, legs for wrought tables, chair backs, bars, ornamental wrought railings, metal doors and windows, ornaments for fences, flower pots, pergolas and wrought sculptures.