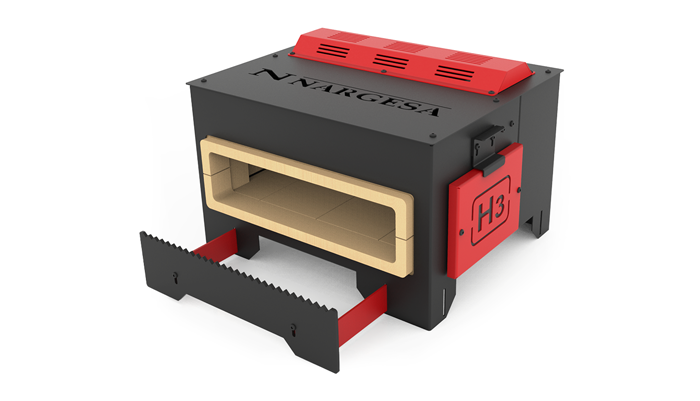

NEW Furnace for the Artistic Forging Nargesa H2, MORE EFFICIENT, SAFER and 100% RESPECTFUL WITH THE ENVIRONMENT. The Furnace is equipped with two burners to heat the iron and work it: molding, bending, piercing, welding, tempering, forging, shoeing horses...

The NEW H2 Nargesa propane forging furnace has been designed to heat irons more efficiently, more safely and respecting the environment. MORE EFFICIENT: Consume up to 75% less gas and reach a higher temperature than any furnace in its category. (over than 1300ºC). SAFER: It has got new security systems for the operator. Fulfilling the regulation RD919/2006. Certified by the General Laboratory of Tests and Investigations: APPLUS Technology Center. 100% RESPECTFUL WITH THE ENVIRONMENT: Emissions below 0.002% of CO. Internal vermiculite coating, 100% natural and recyclable.

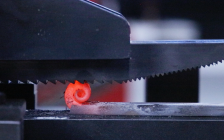

Used in ornamental forge smithies to heat the iron, until it is malleable and can be molded to achieve the desired shapes, work the ends of the rods, manufacture horseshoes, knives, swords, axes, all kinds of pieces of artistic forging, sculptures in iron and wrought iron decoration, iron garden furniture, wrought iron chairs, wrought iron tables... It is a good substitute for the old Forge, much cleaner, faster and more efficient.

Our customers say

Technical features

ADVANTAGES OF THE PROPANE FURNACE H2 FOR THE FORGING

Safety: The safety of the operator is one of the main premises when designing all Nargesa machines. The H2 forging furnace has got all the necessary safety devices for the well-being of the operator that will handle it and it is according to the regulations in force in Spain, the Regulation of appliances that use gas as fuel RD919 / 2006.

- Automatic electronic ignition: Prevents the operator from inserting his hands in the combustion chamber to turn on the gas. No tool is necessary to generate the spark.

- Gas system integrated in the furnace structure: The components were totally protected from impacts that could damage and cause leaks.

- Insulation of the combustion chamber: These elements are formed by a 100% natural material, compacted vermiculite, not harmful to health. 100% recyclable as it does not include glass fibers or ceramics.

- Anti-return valve: This valve regulates the direction of the gas flow preventing it from being addressed to the cylinder.

- Thermocouple safety valve: This device closes the passage of the gas when the combustion chamber cools due to an anomaly, avoiding any possible leak.

Energy efficiency: Saving energy is another topic that our R & D department takes into account for the furnace.

- Fuel consumption: The consumption of Nargesa furnaces has been reduced in a 75%, that is to say, it consumes 1/4 of the fuel used by the same furnaces in its category. With a LPG propane gas cylinder of 35Kg, the H2 Furnace will operate 50 hours with its two burners at full operation. If we only use one burner, then performance will duplicate.

- Gas losses: There is no fuel fuel, all the propane gas that enters the combustion chamber burns, without any sort of waste. This process has been possible due to the new burners, which have been designed and manufactured by Nargesa.

Respect for the environment: It is totally unfeasible to manufacture machinery and not to take into consideration the planet we inhabit.

- Insulating material: The insulating material of the combustion chamber, the compacted vermiculite, is a 100% recyclable material and does not generate waste, increasing the heating (thermic) power of the cavity, over 1300ºC.

- CO Emissions: The emissions emitted by the furnace are 0.002%. In normal environment this value is between 0 and 2. Certified by the General Laboratory of Tests and Investigations: APPLUS Technology Center.

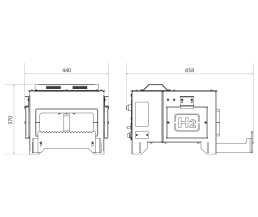

TECHNICAL CHARACTERISTICS

- The Nargesa H2 propane oven has two burners.

- Automatic electronic ignition.

- Gas hose made of stainless steel: this characteristic prevents it from collapsing and burning. This hose does not expire, so it is not necessary to replace it.

- Precision pressure regulator with built-in pressure gauge, allows to adjust the gas pressure more precisely.

- Integrated bar support and adjustable to the different lengths of material. Its shape prevents the material from sliding laterally.

- Possibility to place the material support in any of the three entries.

- Needle flow regulation valves, a lot more accurate.

- All burners can operate independently. A vermiculite separator is supplied with the Furnace to reduce the size of the combustion chamber and thus the heat is not dispersed.

- Double insulation of compacted vermiculite, to avoid heat loss.

- Insulating flange in the material inlets to keep the heat inside the combustion chamber.

- The furnace is covered with heat painting to protect and prevent from heat loss.

- Air flow regulator to adjust this size to the different altitudes. Depending on the work place of the furnace and its altitude regarding the sea, the air flow for the mixture of gas and marine air will be regulated, the suitability for a good combustion.

- Reach temperature, 1300ºC.

- Entries dimensions: 280x100mm (front) 140x100mm (side)

- Adjustable pressure from 0.1 to 1.5 Bar.

- Maximum consumption at 1 bar of 0.7 Kg/h.

- With a LPG propane gas cylinder of 35Kg, the H2 Furnace will operate 50 hours with its two burners at full operation. If we only use one burner, then performance will duplicate.

- LPG Propane Gas Feed.

- Useful internal cavity of the H2 furnace: 324mm wide x 100mm high and 240mm deep.

- Maximum material capacity Ø 80mm.

- Removable side doors to work in the center of the iron bars. The doors are installed without using tools.

- All components are standard and easy to find in any warehouse or hardware store.

- The Nargesa H2 forging furnace is shipped completely assembled.

Its simplicity, dimensions, easy ignition and fast reach of the optimum temperature to work, make out of this furnace a very effective appliance. The Forge Furnaces H1, H2 and H3 comply with the current regulations in Spain, of the Regulation of appliances that use gas as fuel RD919/2006.

High performance of the fraguas de forja Nargesa

The design of the components and the way of operation of the NEW Forging furnaces Nargesa make them a much more competent and productive tool. Energy efficiency is one of its main features, so we have achieved that these forges consume a quarter of fuel that the same equipment in its category, reducing fuel consumption and maintaining all its capabilities.

+ Info for Gas forge H2

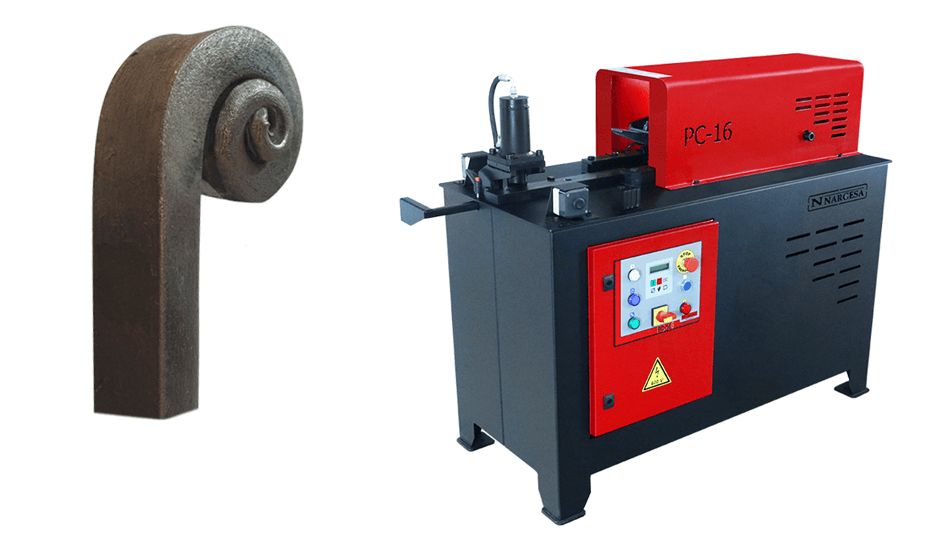

Use Nargesa gas forges for all kind of ornamental forging, to make horseshoes, roll up the snail forged shaped, iron mold, endtreatment of parts,...

You may combine both, Nargesa Furnaces and Power hammers MP60 and End Hot Forging Machines NF70 and PC16, to achieve a lot of ornamental shapes with minimum effort and maximum speed.

Dimensions of the machine Gas forge H2

Characteristics of the packaging Gas forge H2

Nº Pallets: 1.

Width: 800 mm.

Length: 600 mm.

Height: 600 mm.

Volume: 0,288 m3

Nett weight: 40 Kg.

Gross weight: 50 Kg.

Tariff Item Code: 84171000

Other Features:

- The Nargesa H2 forging furnace is shipped completely assembled.

- Packaging with wooden pallet and 3-layered cardboard box, suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

Uses of the machine Gas forge H2

The H2 Nargesa propane forging furnace was designed to heat iron. Used in ironworks to make pieces of ornamental forge, heat the material and thus be able to mold it to get the desired shapes: molding, bending, piercing, welding, tempering, forging, shoeing ... working the ends of the bars, making horseshoes, knives, swords, axes, all kinds of pieces of artistic forging, iron sculptures and wrought iron decoration, furniture iron for garden, wrought iron chairs, wrought iron tables...