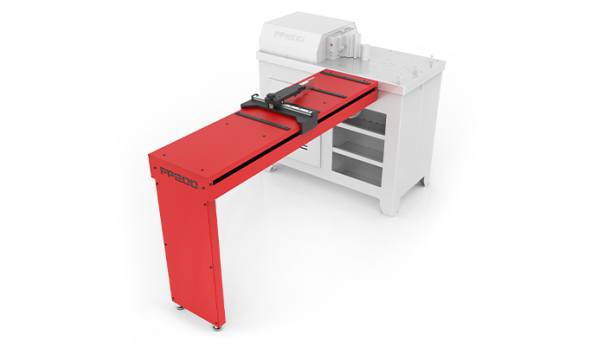

The new bending simulator software for the PP200CNC Horizontal Press Brake is the ultimate tool for manufacturers and operators looking to maximize productivity and accuracy. It is ideal for improving the performance of bending operations and for training future operators, guaranteeing optimal results from the first part while saving time and eliminating material waste.

Developed for Windows environments, it offers a perpetual license with no monthly or annual subscriptions. It allows users to create bending programs in numerical or graphical mode remotely, from a computer, without occupying either the machine or the operator.Technical features

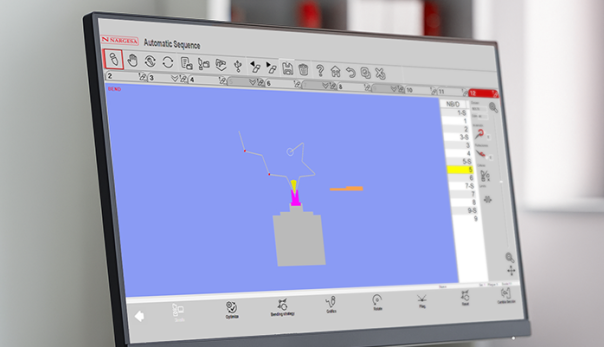

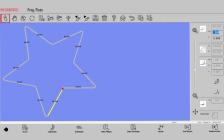

The Bending Simulation Software generates the program from a blueprint or technical drawing, identifying the bend lines and determining the optimal backgauge sequence for each operation. It performs a collision analysis to determine whether the desired part is feasible and automatically calculates the flat pattern of the sheet to be cut, completely eliminating the risk of errors.

Once the program has been generated, it can be saved to a USB drive and later imported into the machine to start production, ensuring optimized cycles with hundredth-of-a-millimetre accuracy.

Forget about spending time figuring out how to produce a specific part. The software itself determines the different ways to manufacture the part.

Advantages of the PP200CNC bending simulator in production

- Offline programming: Very simple and intuitive: in less than 3 minutes you can obtain the program for a truly complex part.

- Direct USB export: Save the program to a USB drive, import it into the PP200CNC and start producing immediately!

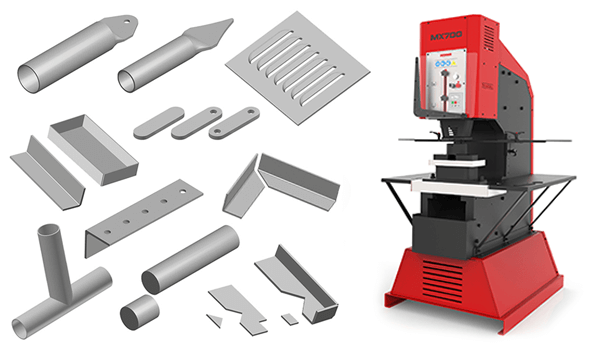

- Automatic calculations with hundredth-millimeter accuracy: By simply entering the data from a technical drawing, the bending simulation software calculates the flat development of the sheet, the final internal radius, the minimum required tonnage, the backgauge dimension and the best solution to manufacture the part.

- Collision analysis: Detects and prevents possible collisions between the tool, machine and part during the bending process, determining process feasibility and ensuring safety.

- Bending process optimizer: Automatically calculates bending parameters such as part orientation and bending angle, based on the characteristics of the material and the final part, taking into account criteria such as productivity and operator safety.

- Back gauge sequencer: Determines the exact position of the gauge at each step of the process. If there is no automatic back gauge available, the software indicates to the operator the position of the different stops.

- Multi-machine compatibility: Can work with different brands and models of press brakes, allowing users to simulate the bending process on a wide range of equipment.

- Perpetual license: Developed for Windows environments, the software offers a perpetual license with no monthly or annual fees, ensuring that the simulator remains operational in the long term.

Advantages for training centres and vocational schools

- Ideal for training: Allows practising and assessing bending processes in a virtual environment without occupying or stopping real machines, reducing risks, material consumption and setup times in the classroom or lab. Ideal for training operators before they use a real machine.

- Virtual simulation: Enables work with realistic virtual simulations, graphically displaying positions and possible collisions in a clear and understandable way. It saves machine downtime and trial material, guaranteeing accurate results from the very first part.

- Sequence optimisation: Makes it possible to optimise the order of bends using 2D graphical generation and to adjust bending parameters in order to provide the most efficient and safest sequence for the operator.

- Intuitive interface: Offers a highly intuitive graphical interface that allows operators and programmers to interact easily with the software, speeding up setup and execution of bending simulations.

- Affordable licence: A perpetual licence that enables vocational schools, institutes and technical academies to incorporate a professional tool without compromising their budget. It allows students to learn using software that is used in real industrial environments.