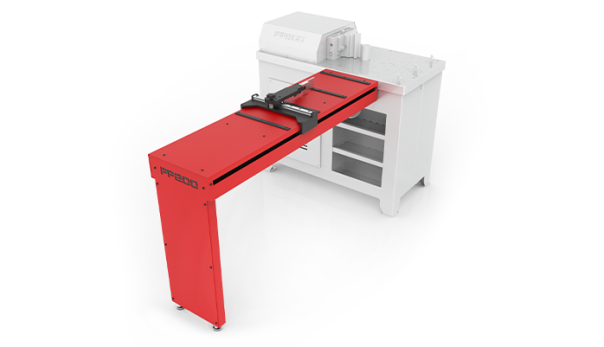

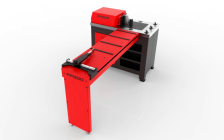

Positioner stop for the PP200 CNC horizontal bending press: Optimized resources, maximum profitability and operational efficiency guaranteed. The positioner stop minimizes manual interventions all while increasing productivity and reducing the time it takes for positioning in different cycles. It offers simple and accessible programming, ESA S625 CNC control, connectivity, 4.0 technology, safety, durability, reliability, two speeds and the utmost precision.

The Positioner stop is an accessory designed and manufactured to get the greatest performance out of the Nargesa Horizontal Hydraulic Press Brake PP200CNC. This positioner stop for the Nargesa PP200 CNC horizontal bending press offers increased productivity and a reduction in the time it takes for positioning in the various work cycles. This innovative design provides the capability of automatically positioning the X-axis during different operations programmed and calculated using the ESA S625 CNC control. This approach significantly helps enhance the operating features as well as the quality of work done with this machine. The implementation of the positioner stop in the PP200 CNC enables individual and mass part manufacturing with considerably higher precision, speed and repetitiveness in comparison to traditional manual methods.

All Nargesa products are adapted to EC industrial machinery manufacturing standards.

Technical features

The positioner stop for the Nargesa PP200 CNC horizontal bending press minimizes manual interventions all while increasing productivity and reducing the time it takes for positioning in different cycles:

ADVANTAGES

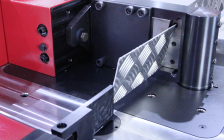

- Precise positioning: Powered by a 1Nm ESA servomotor and moving on high-precision linear guides and ball recirculating skids.

- ESA servomotor: Maximum capacity for specific positioning and extremely precise response to signals from the ESA S625 CNC control unlike those made by other manufacturers.

- Automatic reverse: For all operations there is a fully adjustable safety positioning gauge withdrawal movement.

- Advanced automation: Programming and control by using an ESA S625 CNC that allows manual intervention to be minimized, increasing productivity and reducing positioning times in the different cycles.

- Automatic X-axis positioning: It offers impressive ±0.02mm precision.

- Manual adjustment of cross-carriage the on the Z-axis: It covers all operational possibilities offered by the PP200 CNC flat press, including bending, punching and curving.

- Intuitive user interface: Programming and configuration of all Positioning gauge functions are ruled by an interface designed to be simple and intuitive for the user, thus being accessible to all operators regardless of their level of experience.

- Connectivity and 4.0 technology: The 4.0 technology incorporated into the software gives the customer the possibility of establishing a remote connection with the Nargesa technical service through the Internet, thus permitting realtime software updates, resolution of any anomalies and instant assistance.

- Maximum safety for the operator: Operator safety is a top priority! The multi-speed movement, together with the action on the pedal, allows absolute control by the operator. All moving components of the stop operating and control mechanism are protected within the structure itself and thus avoiding any risk of entrapment.

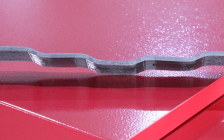

- Durability and Reliability: Its main structural frame is formed by various duralumin alloys, to which anodizing is applied to resist any environmental challenge. Positioning supports manufactured with high alloy mold steel, thus offering high hardness and durability. For the most exposed area of the work table, we have slats made of Hardox®400, a special steel with high hardness and wear resistance.

- Movement in two speeds: The automated gauge software manages two working speeds, one at maximum speed while outside the safety area, and a significantly slower one for movements within this zone.

- Universal Compatibility: The configuration of the automated gauge makes it compatible with a wide variety of materials, dimensions and work processes in both Metric and Imperial systems.

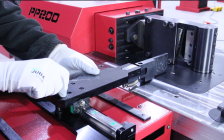

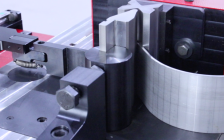

- Two Fingers supplied as standard with the Gauge: The automated stop is equipped as standard with two position supports or “Fingers”: The Flat Support has a large support surface, to work relatively far from the central axis of the machine. The Needle Support has a thinner surface ideal for short-wing folding work, that is, it allows it to be positioned between the die and the punch without interfering.

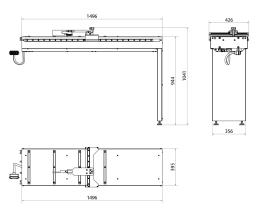

General characteristics:

- Electric motor: Servomotor 0,9Nm, 0,520kW, 5000rpm

- Electrical power: 480V, 400V ,220V Three-Phase · 220V Single-Phase

- X axis stroke length: 1210 mm

- Z axis stroke length: 300 mm

- Displacement speed:1000mm /s

- Positioning accuracy: ±0.02 mm

- Repeatibility: ±0.02 mm

- Maximum structural load: 2.000 Kg

- Dimensions: 1496x1041x426 mm

- Weight: 115 Kg

All of our products are made at our facilities in Spain. The hydraulic and electronic components are completely standard and from the best leading European brands with technical assistance services throughout the world: Rexroth, Bosch, Roquet, Schneider Electric, LG, Telemecanique, Pizzato etc.

+ Info for Automated Gauge for the PP200CNC Horizontal Press Brake

The ALL-NEW positioner stop for the Nargesa PP200 CNC horizontal bending press represents a significant advance in manufacturing efficiency and precision. In comparison to the previous manual system, this positioner stop makes it possible to create unique as well as standard parts with greater precision, speed and repetitiveness. The resources are completely optimized, and ensure the greatest of machine and accessory profitability with fully guaranteed operational efficiency. The most outstanding elements of the new design include:

- Maximum precision: At Nargesa, we’re experts in vertical and horizontal bending to perfection thanks to more than a half century of experience manufacturing bending machines. This allowed us to create an all-new positioner stop with the greatest mechanical precision and high speed movement.

- Servomotor: Unlike those made by other manufacturers, the servomotor on the positioner stop for the Nargesa PP200 CNC horizontal bending press allows us to offer controlled, rapid and constant speed. Communication between the positioner stop and the machine is via CAN BUS, an internal communication system that’s key in industrial environments. The CAN system transmits data at high speeds, is resistant to electromagnetic interference and offers real-time synchronization. It also features a resolver, a sensor that converts angular movement into electric signals used to feed information back to the machine’s control systems. All of this technology prevents accidental collisions with the operator handling the machine.

- Brief programming: Even the most complicated part can be programmed in under 60 seconds.

- Drive by ESA servomotor and HTD crowned belts that allow automatic positioning of the “X” axis with a precision of ±0.02mm.

- Manual adjustment of the cross slide, “Z” axis to cover all the operation possibilities offered by the PP200CNC horizontal press, folding, punching, bending...

- Longitudinal movements of both carriages using high-precision linear guides and recirculating ball runners.

- Automatic anti-collision control managed by the software itself.

- Easy mechanical and electrical installation for quick set up and run.

Therefore, the positioner stop not only enhances precision and speed when manufacturing parts, but also leads to greater versatility and ease of use as an advanced solution for bending, punching and curving operations in the industry.

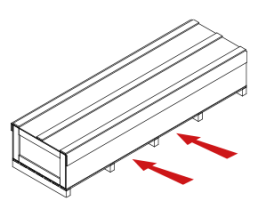

Dimensions of the machine Automated Gauge for the PP200CNC Horizontal Press Brake

Characteristics of the machine: 1496x1041x426 mm

Weight: 115 Kg

Tariff Item Code: 84669400

Other characteristics:

- We supply 4 eyebolts to comfortably handle the positioner stop and couple it to the horizontal bending press safely. It can also be coupled by several operators together.

- The automated positioner stop comes with the necessary parts to be coupled to the horizontal bending press.

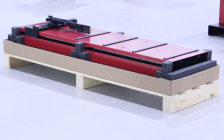

Characteristics of the packaging Automated Gauge for the PP200CNC Horizontal Press Brake

Nº packages: 1

Width: 1620 mm

Length: 540 mm

Height: 460 mm

Volume: 0,40 m3

Nett weight: 115 Kg

Gross weight: 127 Kg

Tariff Item Code: 84669400

Other characteristics:

- Packaging with wooden pallet NIMF15 and 3-layered cardboard box suitable for sea freight.

- Optional: Complete wooden packaging NIMF15.

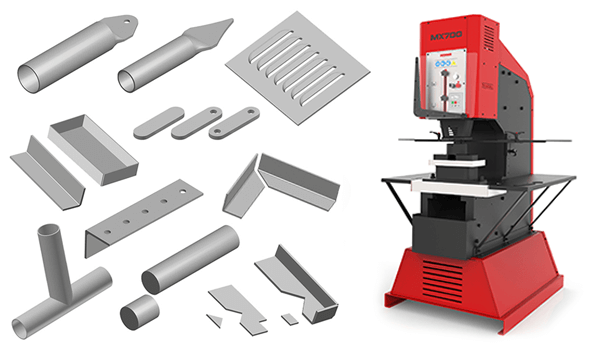

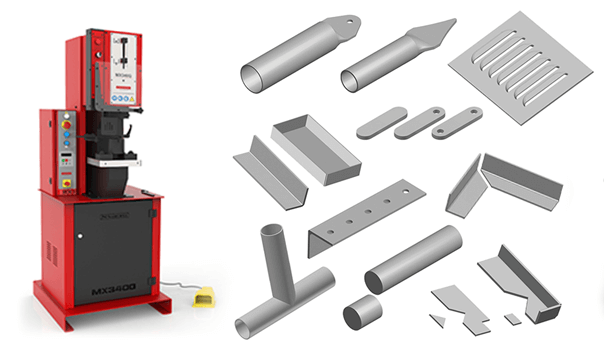

Uses of the machine Automated Gauge for the PP200CNC Horizontal Press Brake

The uses for the positioner stop for the Nargesa PP200 CNC horizontal bending press are based on manufacturing efficiency and precision, mostly for bending, punching and cutting. These functions enable a number of operations on different materials and profiles for versatility and efficiency in all sorts of areas. The positioner stop for the Nargesa PP200 CNC horizontal bending press offers the opportunity to bend plates, fold plates, punch plates, harden profiles, bend profiles, cut plates, shape clamps, punch holes into plates, cut railings, die-cut, hollow out tubes, cut fluting iron, die-cut plates, widen tubes, hollow out spouts, shorten the ends of tubes, shape bars, perforate plates, etc. The applications for these operations are endless and include the manufacture of frames, rails, railings, chairs, tables, shelves, aircraft seats, bicycles, collector rods, wheelchairs, ventilation systems, heating systems, air conditioning systems, handrails, stairs, works of art, beams, columns, rods, electric towers, excavators, cranes, solar panels, aircraft wings, vehicles, trains, planes, balconies, walkways, boats, shelving units, piping, antennas, busbars, communication towers, etc.