Frequently Asked Questions about NARGESA Horizontal Press Brakes

What types of materials can be bent with these presses?

Horizontal press brakes are extremely versatile machines capable of working with both metallic and non-metallic materials, adapting to a wide range of industrial applications and production levels.

Compatible metallic materials:

These machines can bend, cut, shape, punch, and even reduce parts made of:

- Carbon and alloy steel

- Stainless steel

- Aluminum

- Brass

- Copper

Thanks to their power and precision, these presses allow processing different types of steel according to their alloys and ductility, adapting to the requirements of each job.

Non-metallic materials:

In addition to metals, horizontal presses can also work with technical materials such as:

- Composites

- Aluminum composite panels (Alucobond or Alucobon type)

- Technical plastics (depending on rigidity and temperature)

This makes them a flexible solution not only for metal workshops but also for companies manufacturing panels, technical furniture, signs, and architectural elements.

Types of profiles that can be bent

Horizontal presses are capable of working with a wide variety of profiles and shapes, regardless of the material:

- Flat or preformed sheets

- Flat bars of various thicknesses

- Square or rectangular tubing

- Round tubing, including bending

- Structural angle profiles (L)

- T, U, and Z profiles

Thanks to their interchangeable tools and advanced CNC systems, such as in the Nargesa PP200, it is possible to adapt the bending process to different formats, thicknesses, and production needs.

What is the maximum sheet thickness that a horizontal press can handle?

The bending capacity of a horizontal press brake depends directly on the pressing force (tonnage) the machine can exert, as well as other key factors such as material thickness, type, bending length, and the V-die opening.

Although a press may seem low in tonnage, for example, 20 tons, it is important to know that all the force is concentrated in a very small area. This allows thick sheets to be bent over short lengths with high precision and safety.

For example, the Nargesa PP200 model includes an intelligent CNC system that:

- Informs the operator whether the bending is possible.

- Automatically calculates the required tonnage.

- Suggests the appropriate V-die opening.

Practical example of bending capacity

- A 20-ton press can bend:

- 25 mm thick sheet.

- Bending length: 100 mm.

- V-die used: 200 mm.

Quick formula to calculate bending capacity

If there is no CNC system, a practical and reliable formula can be applied:

Tons per meter ≈ Thickness (mm) × 8

Ideal V-die opening ≈ Thickness (mm) × 8

All calculations are based on carbon steel with an approximate resistance of 45 Kg/mm².

Application examples:

5 mm sheet (carbon steel)

- Ideal V: 5 × 8 = 40 mm

- Force per meter: 40 tons

- For 100 mm length: 4 tons

8 mm sheet

- Ideal V: 8 × 8 = 64 mm

- Force per meter: 64 tons

- For 100 mm length: 6.4 tons

Factors you should always take into account:

- Material thickness.

- Type of material (steel, stainless, aluminum, etc.).

- Bending length (bending 100 mm is not the same as 1 meter).

- V-die opening used.

Reference table of tonnage per meter (carbon steel):

- Thickness: 3 mm | Recommended V: 24 mm | Tons per meter: 24 Tn

- Thickness: 5 mm | Recommended V: 40 mm | Tons per meter: 40 Tn

- Thickness: 8 mm | Recommended V: 64 mm | Tons per meter: 64 Tn

- Thickness: 10 mm | Recommended V: 80 mm | Tons per meter: 80 Tn

- Thickness: 12 mm | Recommended V: 96 mm | Tons per meter: 96 Tn

*Remember that if you only bend 100 mm in length, that force is divided by 10.

Can it be used for bending parts as well as folding them?

Yes, horizontal press brakes are not only used for folding sheets and profiles, but they also allow precise bending of metal parts such as tubes, handrails, flat bars, and structural profiles.

One of the most effective techniques for bending materials with this type of machine is to use a mold and a counter-mold with the desired shape. The material is placed between them and, by applying the necessary force, the piece bends by copying the mold’s geometry.

Keys to efficient and safe bending

- It is essential that the press has a pressure regulator that allows applying only the exact force needed for the bending operation.

- This way, tooling damage is avoided, and the mold’s service life is ensured.

- This technique is ideal both for repetitive curves in series production and for unique or custom pieces.

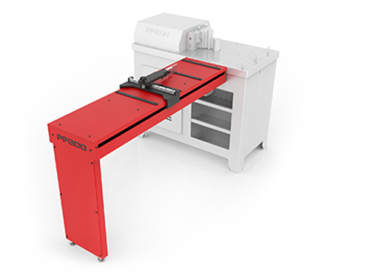

Versatility of the Nargesa PP200 horizontal press

The Nargesa PP200 has been designed with maximum operator flexibility and adaptability in mind:

- It has multiple holes on the table that make it easy to bolt on any type of special tooling or bending mold.

- The head incorporates three simple and quick clamping systems, which facilitate tool changes and improve productivity.

- This makes the PP200 an ideal solution for folding, bending, drawing, straightening, or punching operations—all in a single machine.

Yes, a horizontal press brake is perfectly suitable for bending metal parts as well as folding them. Its design, especially in models like the Nargesa PP200, allows multiple forming tasks to be carried out efficiently, safely, and with a high level of precision.

One of its greatest strengths is, without a doubt, its versatility.

What are the most common industrial applications for this type of presses?

Horizontal press brakes are highly versatile machines, which is why they have a wide range of industrial applications, especially in forming processes, metal part manufacturing, and series production.

Below are the most common applications, classified by sector:

Most common industrial applications of a horizontal press brake

1. Boilermaking and metal structures

- Folding and bending of sheets, flat bars, and structural profiles (L, T, U, Z).

- Manufacturing all kinds of clamps, both flat and curved, for fastening pipes, conduits, structures, machinery, or electrical systems.

- Forming brackets, reinforcements, supports, structural connectors, and joining parts.

- Straightening or correcting deformed parts during the welding or handling process.

2. Metal carpentry

- Manufacturing railings, handrails, and door and window frames.

- Bending square or round tubes for gates, grilles, and decorative structures.

- Bending aluminum or stainless steel profiles for enclosures.

3. Automotive industry

- Forming structural parts for bodywork, frames, or chassis components.

- Producing fastening parts, anchors, and metal supports.

- Bending parts for exhaust systems, wheel arches, and door reinforcements.

4. Machinery and tooling manufacturing

- Producing custom parts such as base plates, supports, connectors, or housings.

- Building customized molds and counter-molds.

- Manufacturing spare parts in low volumes.

5. Metal furniture and decoration

- Bending profiles for tables, chairs, shelves, or decorative structures.

- Bending tubes for industrial design, lighting, or technical carpentry.

- Applications in modern architectural design using steel or aluminum.

6. Electrical sector and electrical panels

- Folding galvanized sheet or stainless steel to manufacture electrical cabinets, enclosures, cable trays, and conduits.

- Forming metallic fastening components, supports, and anchors for electrical installations.

- Bending copper busbars used for current conduction in power panels, transformers, and electrical distribution systems.

Horizontal presses allow copper busbars to be bent with great precision, adapting the exact shape and angle without damaging the conductive material, which is essential to ensure a good electrical connection and avoid losses or overheating.

7. Series production and automation

- In automated industrial environments, horizontal presses with CNC and the possibility of integrating collaborative robots allow the production of large volumes of parts with minimal human intervention.

Advantages for the industry:

- High precision and repeatability in folding or bending.

- Possibility of partial or full automation.

- Adaptable to multiple tasks with interchangeable tooling.

Ideal for small, medium, and large companies.

What accessories or tooling are compatible with Nargesa horizontal press brakes?

Nargesa horizontal press brakes, such as the PP200 model, are designed with a robust and modular structure that allows them to work with a wide variety of standard and custom tooling, offering maximum compatibility and industrial versatility.

Compatibility with commercial tooling systems

These presses are compatible with:

- Bending tooling with the Promecam system (international standard).

- Possibility of adapting on demand systems from:

- Amada

- Colly

- Other commercial format

Adaptation to the customer’s dies and tooling

One of the greatest advantages of Nargesa presses is that they can use:

- Dies and punches already available in the customer’s workshop, as long as they are in good condition and within the machine’s specifications.

- Special tooling custom-made by the customer or third parties.

- Original Nargesa tools and accessories.

This makes it possible to maximize existing resources and reduce investment costs in new tooling.

Flexible and safe mounting

Thanks to their functional design:

- The table and the head have numerous threaded holes that allow any type of tool, mold, or workpiece holder to be bolted on.

- The head has three quick and versatile clamping systems to facilitate tool changes without modifying the structure.

Nargesa horizontal presses are not only compatible with the main tooling systems on the market, but they also accept dies, tools, and accessories already available in the customer’s workshop. This total compatibility makes the PP200 a flexible, cost-effective, and durable machine—ideal for adapting to any production environment.

Do these presses allow straightening or drawing operations?

In addition to folding and bending, horizontal press brakes also allow other highly demanded industrial operations, such as straightening deformed parts or drawing and reducing tubes.

Straightening defective parts

Straightening operations are very common with this type of machine. They allow bent, twisted, or misshapen metal parts to be recovered, avoiding waste and reducing production costs.

- Ideal for correcting errors after welding, cutting, or handling processes.

- Suitable for profiles, flat bars, tubes, beams, and deformed sheets.

- Nargesa offers a special straightening die compatible with its models, designed to facilitate this task on different material sections and formats.

This operation is key in boilermaking, blacksmithing, metal construction, and industrial maintenance.

Drawing and reducing tubes

Another frequent application is reducing the diameter of tubes.

- Allows one tube to be inserted into another, enabling telescopic or nested connections.

- Used in the manufacture of knock-down metal furniture, lightweight structures, and modular systems for greenhouses, scaffolding, etc.

- Optimizes transport, as parts can be shipped disassembled and assembled at the destination.

This operation is also very useful in the manufacture of awnings, tents, carts, metal shelving, and pergolas.

Nargesa horizontal presses are true multifunction workstations, capable of performing folding, bending, straightening, drawing, and reducing with the same precision and robustness.

This versatility allows companies to expand their production capacity without the need to purchase multiple machines.

Do they require specialized maintenance?

In the case of the Nargesa PP200 model, the answer is no. Unlike other horizontal presses on the market that may require periodic lubrication, technical adjustments, or regular inspections, the PP200 has been designed to operate without specialized maintenance.

Minimal maintenance and no additional costs

The mechanical design of the PP200 horizontal press has been conceived to offer maximum reliability with minimal maintenance. There are no complex electronic components or hydraulic systems that require periodic servicing.

The only recommendation is:

- Keep the worktable clean and well cared for to ensure precision and prevent the accumulation of metallic debris.

Advantages of a maintenance-free machine

- Savings in operating costs

- More productive uptime without interruptions

- No need for specialized technical personnel for maintenance

- Reduction of unplanned downtime

The Nargesa PP200 horizontal press stands out not only for its versatility and precision, but also for its complete absence of technical maintenance, making it a valuable tool for workshops, industries, and SMEs looking for efficiency and reliability without hidden costs.

Is it possible to automate the folding process?

Yes, horizontal presses equipped with CNC (computer numerical control) are perfectly automatable, which makes them ideal for modern and efficient production environments.

In particular, the Nargesa PP200 model has been developed with integration into robotic systems in mind, without the need for large investments or complex configurations.

Automation with a collaborative robot

The Nargesa PP200 is equipped with an open and intelligent CNC, which allows it to:

- Connect to any standard robot on the market, whether collaborative or industrial

- Perform automated tasks such as feeding parts, positioning, folding, and extraction, without manual intervention

- Implement simple, fast, and low-cost automation, ideal even for small and medium-sized companies

Benefits of automation in a horizontal press

- Increased productivity and repeatability

- Reduction of human errors in folding or bending

- Continuous operation without direct operator presence

- Possibility of running unattended shifts

Seamless integration

Thanks to its technical design:

- No complex programming is required

- Compatible with standard automation systems (PLC, collaborative robots, robotic cells)

- The CNC includes digital inputs and outputs ready for direct integration

The Nargesa PP200 horizontal press is a solution ready for industrial automation, without the need for costly additional developments.

Its compatibility with robots and open CNC control allows companies to automate processes in an accessible way, increasing efficiency without losing flexibility.

What training is required to operate a horizontal press?

The training required to operate a horizontal press depends mainly on the machine model and the type of control system it uses. There are very simple machines that do not require formal training, and others more advanced with CNC (computer numerical control) that offer greater capabilities, but also require some basic learning.

There are presses on the market that operate with mechanical limit switches and have no digital control. These are extremely basic and do not require specific technical training, making them suitable for repetitive, low-complexity tasks.

Minimal training on CNC presses: the case of the Nargesa PP200

The Nargesa PP200 model, despite incorporating an advanced CNC, has been designed with a very clear focus: maximum ease of use from day one.

Advantages of the PP200 CNC:

- Intuitive interface with different programming levels

- Possibility of operating by entering only two simple values (angle and length)

- More advanced options available but equally easy to program

- Complete manual and step-by-step audiovisual manual included

- 95% of users operate the machine on the same day of installation, without requiring external technical assistance

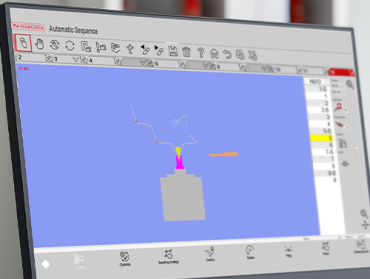

External programming software

Nargesa also offers optional external software that can be installed on any customer computer. This software:

- Allows simulating the folding before performing it

- Warns if the part is feasible according to real parameters

- Automatically generates the CNC program, without the operator needing to make calculations or program manually

This minimizes errors and saves valuable time in each production.

Specialized training is not required to operate the Nargesa PP200 horizontal press brake. Its CNC has been developed to be simple, fast, and functional, allowing any operator with basic knowledge to start working in minutes.

In an environment where time is money, this ease of use becomes a strategic advantage.

Can repetitive bending series be programmed with CNC control?

Yes, the Nargesa PP200 horizontal press brake, equipped with CNC numerical control, allows programming and executing repetitive bending series automatically, precisely, and quickly. This function is ideal both for series production and for single-piece manufacturing where repeatability, precision, and time savings are required.

The PP200 CNC allows you to:

- Program complete folding sequences, save them, and run them repeatedly

- Simulate roll bending (calendering), i.e., create progressive curves through a sequence of small successive bends

- Adapt to a wide variety of geometric shapes with high precision and professional finish

This expands production possibilities beyond simple straight bending, allowing users to manufacture complex parts with curved or composite shapes, without the need for additional machinery.

Optional software for assisted programming

In addition, the PP200 press offers the option of integrating advanced programming software that:

- Simulates the part on-screen, showing the successive bends in real time

- Evaluates the manufacturability before executing the part

- Suggests the best bending sequence to optimize the work cycle

- Automatically generates the CNC program for the machine

This software is ideal for users who want to:

- Avoid manual programming errors

- Save time on setup and testing

- Optimize productivity and final quality

Benefits of advanced CNC programming

- High precision and repeatability in every cycle

- Reduction of downtime and adjustment errors

- Improved finishes and tolerances

- Possibility to access new markets and products thanks to the system’s versatility

With the Nargesa PP200 horizontal press, it is not only possible to program repetitive bending series, but also to perform complex simulations such as roll bending and optimize each part thanks to an intuitive and powerful CNC.

This technology makes it possible to increase productivity, improve finishes, and expand workshop capabilities efficiently and profitably.

Are the presses approved according to European safety regulations?

Yes. All Nargesa horizontal press brakes, like the rest of their industrial equipment, are designed, manufactured, and certified in accordance with current European regulations on machinery and safety.

Full compliance with CE regulations

Nargesa presses:

- Are approved under the framework of the European Union.

- Comply with the European Machinery Directive 2006/42/EC, ensuring the machine is safe to use.

- Incorporate all the necessary elements to protect the operator and anyone in their working environment, including:

- Emergency stop buttons.

- Mechanical safety devices.

- Safe electrical systems.

- Detailed technical manuals with safe use instructions.

Benefits of regulatory compliance

- Legal and operational peace of mind for the end user.

- Greater reliability in demanding industrial environments.

- Facilitates export and certification in public or private projects within and outside the EU.

- Ensures personnel protection, reducing occupational risks.

Nargesa horizontal presses are fully approved according to European safety regulations, offering a productive, reliable, and safe solution for any industry. Their strict compliance with current legislation reinforces their quality and international positioning.

What hydraulic power does each model in the range have?

At Prada Nargesa, after extensive technical studies and market tests, a clear strategy was chosen: to offer a single model with optimized hydraulic power to cover the majority of real industrial applications.

Hydraulic power of the PP200 model

The PP200 model has a hydraulic power of 20 tons, which allows it to:

- Bend carbon steel sheets up to 25 mm thick.

- Perform bending, curving, drawing, reducing, and straightening operations with total reliability.

- Address more than 90% of common needs in boiler making, metalworking, furniture manufacturing, structures, and industrial installations.

Why only one model?

After multiple studies, Nargesa engineers concluded that:

- A 20-ton machine is more than enough for most common workshop tasks.

- Reducing the number of models allows them to:

- Lower manufacturing costs.

- Offer a more competitive final price for the customer.

- Simplify technical service and spare parts supply.

Advantages of this decision

- Savings for the user without sacrificing working capacity.

- Well-dimensioned power: neither oversized nor insufficient.

- More efficient production and more accessible product.

- Versatile, robust machine ready for multiple applications.

The Nargesa PP200 horizontal press has 20 tons of hydraulic force, carefully studied to offer the best balance between working capacity, cost, and versatility. A single solution that reliably covers the majority of needs in the industrial sector.

What is the typical return on investment in industrial environments?

The return on investment (ROI) of a horizontal press brake such as the Nargesa PP200 is fast, measurable, and proven by the real experience of our customers.

Factors that accelerate the return on investment

ROI depends on several key factors:

- Production volume: the more the machine is used, the faster it pays for itself.

- Avoided costs: such as subcontracting, bending errors, setup times, and production downtimes.

- Versatility: the machine performs multiple functions (bending, curving, drawing, reducing, straightening).

- Automation: when integrated with CNC or a robot, operation times and the need for personnel are drastically reduced.

Real customer data

As many of our users have shared with us:

90% of customers recoup the cost of the machine in less than 12 months.

This fast return is due to:

- High productivity from day one.

- Immediate reduction in operating costs.

- Elimination of downtimes and programming errors.

Why does the Nargesa PP200 offer such a fast ROI?

- Zero specialized maintenance required.

- Extremely fast programming (less than 60 seconds per part).

- Compatibility with external software that automatically generates the program and evaluates the feasibility of the bending.

- Affordable initial investment, ideal for both SMEs and large industries.

The Nargesa PP200 horizontal press is an intelligent and profitable investment, with a return on investment proven by most of our customers in less than a year. Its reliability, low operating cost, and ability to produce high value-added parts make it a key tool to increase the profitability of any workshop or industrial plant.